Determining the Right Nozzle Diameter Size and their Effect on the Performance of Picohydro Technology

DOI:

https://doi.org/10.37934/arfmts.102.1.98113Keywords:

Renewable energy, prototype, pico hydro technology, nozzle, waterAbstract

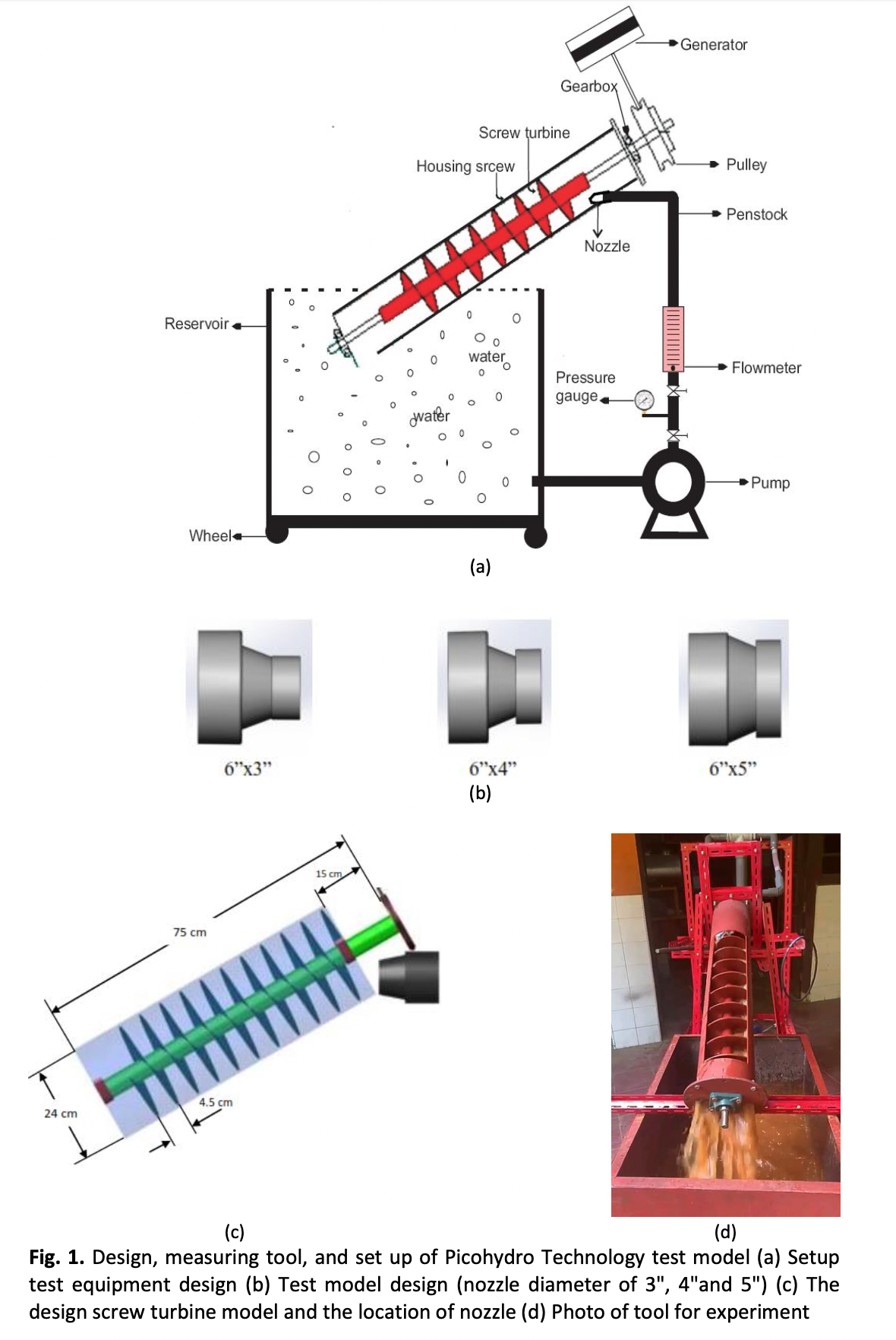

New energy and renewable energy are solutions that can be applied to meet energy needs, especially those that are environmentally friendly. Currently, people, especially those living around energy sources such as rivers and irrigation, can independently create renewable power systems to produce energy. The application of picohydro power generation technology is the best solution in the application of environmentally friendly, independent, and renewable technologies. The purpose of this study was to determine the best performance of the nozzle output diameter of 3", 4", and 5" on picohydro technology using an Archimedes screw turbine. The research method was carried out by means of a prototype experiment using continuously circulated water fluid. The data collection process starts from the water discharge from the flowmeter, the rotation of the turbine blade, the rotation of the transmission, the rotation of the alternator, the pressure in the pressure gauge, and the power generated. The research results obtained information that at the smallest diameter (3") the nozzle pressure to the screw tip is not optimal because the water released by the nozzle only hits part of the screw leaf side, so that the performance is not optimal where the turbine shaft rotation at a maximum discharge of 30 m3/h is obtained at 230 rpm, while if the diameter of the output nozzle is given (5"), a lot of water is sprayed by the nozzle and it fills the screw leaves, which causes water to also overflow onto the screw in front of it, so that the flow does not normally flow from each screw, and it is also possible that the size of the input screw is not proportional to the output screw turbine, where the maximum rotation at a discharge of 30 m3/h is obtained at 247 rpm. For the size (4") it looks higher when viewed from the data obtained, this condition looks ideal in the size ratio between the input and output nozzles so that the resulting flow is also right to drive the turbine screw. The shaft rotation results obtained are 269 rpm for a water discharge of 30 m3/h.

Downloads