Effect of LPG Emission on the Performance of Glass Bending Furnace

DOI:

https://doi.org/10.37934/arfmts.103.1.6474Keywords:

Design of burner, low emission combustion, combustion, LPG, glass bending furnace, swirl burner, heatAbstract

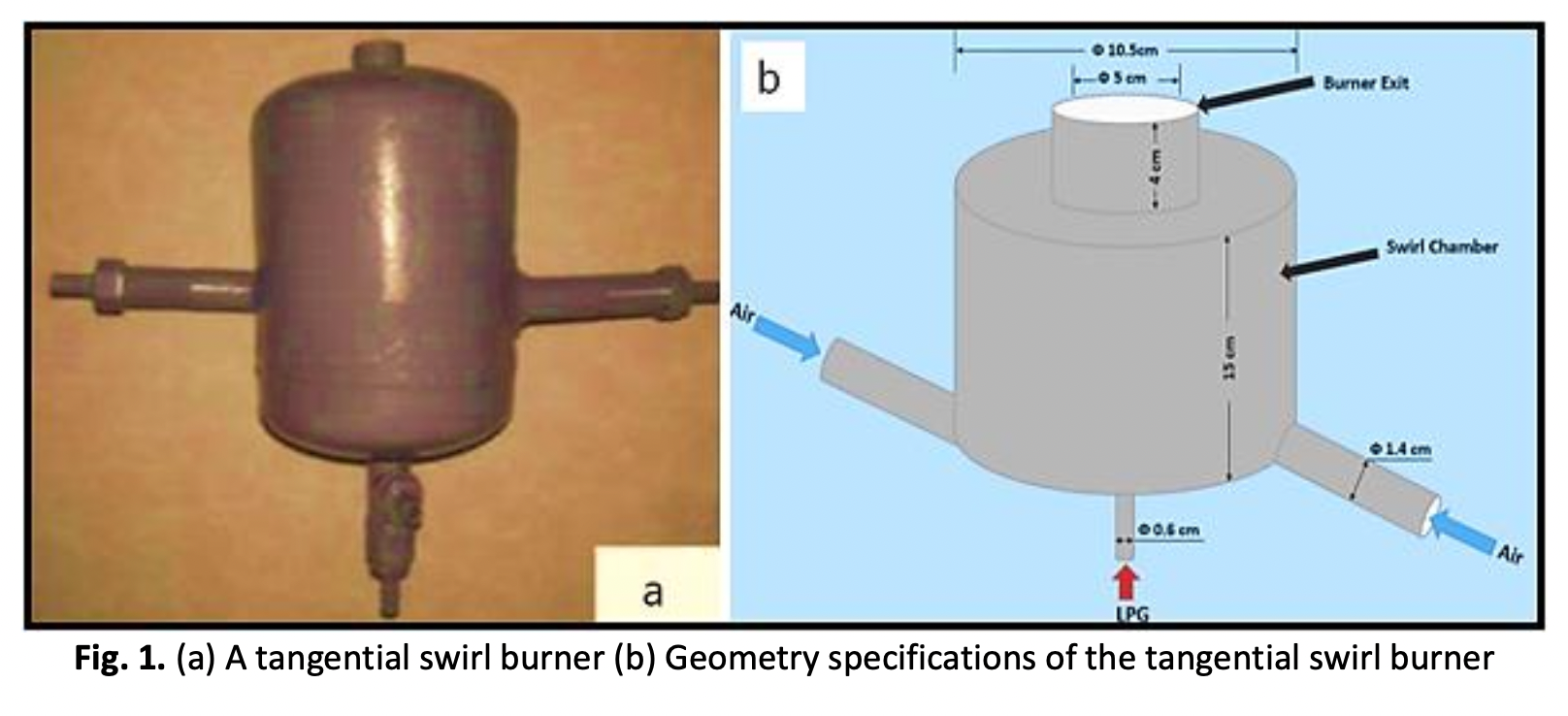

The extant research design LPG give a good temperature distribution for a specific burner design of low consumption burners and relays to a method for bending the glass sheets, in which method the swirl burner LPG is used in a small furnace. Using LPG fuel gives more stability in the combustion process, the LPG is a gaseous fuel that helps to have easy control of the combustion rate and the temperature behavior inside the combustion zone by increasing and decreasing the mixing ratio with air. The heat flux from the flame moves in the front direction due to the momentum of the fuel mixture and the design of the burner rim, which keep the flow adhesive, such behavior leads to creating different temperature zone since the combustion process is a continuous process. The main result is that clean or low emission combustion of LPG fuel will increase the gained temperature and give a good temperature distribution for a specific burner design of low consumption burners and the clean combustion will reduce the unwanted deformation of soot on melting glass surface. Generally, high energy cost and the environmental pollution are the major issues in the glass industries which must be reduced through reduce the fuel consumption of the glass furnaces. For these reasons, this type of furnace can be used in other applications, not only in melting glass.

Downloads