The Influence of Heat Recirculation Segment of Meso-Scale Combustor o Gas and Liquid Fuel Inside Microscale Combustor

DOI:

https://doi.org/10.37934/arfmts.104.1.141151Keywords:

Meso/micro combustor heat recirculation, micro power generatorAbstract

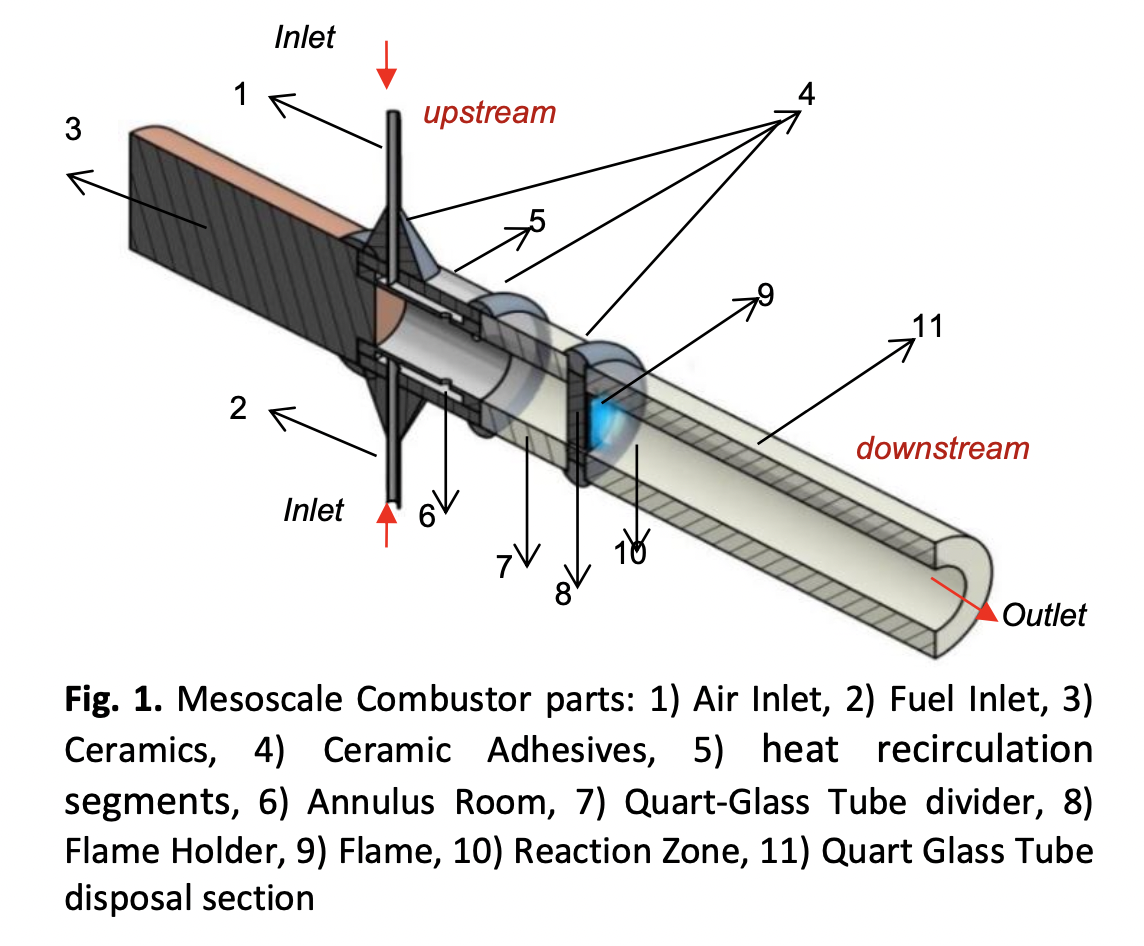

This study aims to determine the effect of heat recirculation segments configuration on the stability of the flame. Mesoscale combustor used is made from duralumin-quart glass tube, and Ø 3.5 mm diameter combustion chamber. The heat recirculation segments part is made of duralumin as a segment of evaporation and air-fuel mixing. Combustor A has heat recirculation segments length of 7 mm, while combustor B has a heat recirculation segments length of 10 mm. The fuel used is liquid hexane and butane gas fuel. The results showed, the stability of hexane flame in combustor A between the equivalent ratio of ɸ 0.73-1.28 temperature can reach 803.8oC. Combustor B is stable at an equivalent ratio of ɸ 0.76-0.98 to a temperature of 580.9oC. Furthermore, for butane flames; combustor A, stable in the range of ɸ 0.68-1.31 temperature to 931.3oC. Combustor B has a stability range of ɸ 0.79-1.41 temperature reaches 857.2oC. Combustor A with a 7 mm heat recirculation segments length is proven to produce wider flame stability, using both liquid fuel and gas. So, combustor A can be recommended to be applied to micro power generators. It should be noted that butane flames appear to have more flame stability than hexane flames. This is because gaseous fuels are more homogeneous (gaseous) so they are more quickly mixed with air.

Downloads