Optimization of Heat Exchanger Network in Olefin Unit of Oil Refinery

Keywords:

Optimization , Heat exchanger network , Heat transfer process , RefineryAbstract

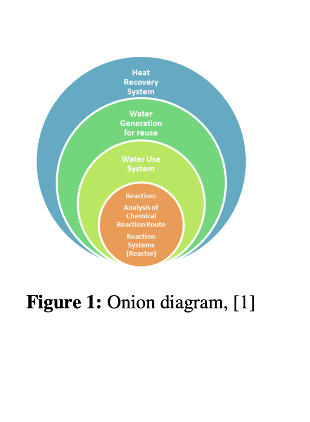

One of the steps to start the optimization is to check the energy use of cold and hot streams from the HEN to utility. In this process, the movement can be either from the first layer to the last layer or from the last layer to the first layer with the purpose of achieving the optimization results in the system. The objectives of the study are to identify the network and exchangers that use more than the energy required, to analyse exchangers required energy saving techniques and to apply the process of optimization in refinery. The analysis were done by formulating the problem and generating mathematical formula to get the best optimization result, which is known as ∆Tmin. This study investigates the systematic approach to retrofit an existing plant using the “Pinch Method”. The method was applied on the distillation unit of Isfahan refinery preheat train. Results show that it is possible to reduce the load of the atmospheric furnace up to 25% and restore the normal operational condition, only by 1MM USD investment. This implies a payback time of 9 months.

Downloads