Experimental Analysis of the Effect of Tube Pass Length on The Characteristics of Heat Transfer in U-Sharp Turned Channels

Keywords:

Heat exchanger, pass length, sharp turn, turbulence flowAbstract

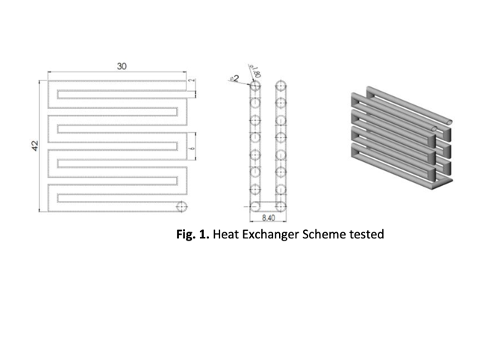

Pipe-shaped ducts with sharp turns are commonly used for flow passages on heat exchangers. Heat transfer characteristics on a sharp turn channel are very complicated; this is due to the emergence of secondary flow caused by turns. In response to this need some researchers have carried out both experimental and numerical studies of heat / mass transfer and fluid flow in rectangular channels with sharp turns of 180 ° for high-speed flow with forced convection heat transfer. Research on the characteristics of heat transfer in tubes with sharp turn technology is still very minimal. Therefore, experimental studies have been conducted to understand the characteristics of convection heat transfer on a U-shaped tube channel, which has a total length of 6 meters, with four variations in the length of the pass and different number of turns. Four combinations of Heat Exchanger (HE) with tube length of 60 cm, 45 cm, 30 cm and 15 cm were drained by hot water into a tube with a temperature of 600C, 700C and 800C, while cooling water with a constant temperature of 260C. The test is carried out until the temperature of the hot water comes out stable with the interval of taking data for 5 minutes. Turbulence flow will increase the heat transfer coefficient on the tube surface.The highest heat transfer coefficient occurs in HE with a length of 30 cm and has 30 turns, while the lowest heat transfer coefficient occurs in HE with a 60 cm pass length and 14 turns.

Downloads