The Effect of Microbubbles on the Reduction of Biochemical Oxygen Demand (BOD) of Palm Oil Mill Effluent (POME)

Keywords:

Wastewater , microbubbles , Palm Oil Mill Effluent (POME) , Biochemical Oxygen Demand (BOD) , treatment time , microbubble flowrateAbstract

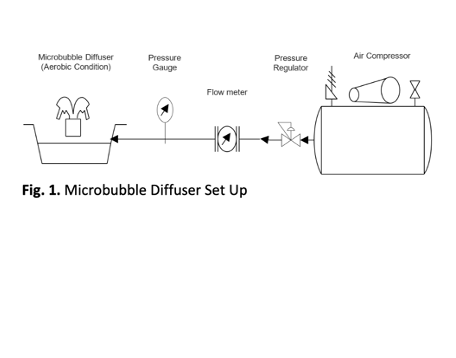

Palm Oil Mill Effluent (POME) is a wastewater discharged from the palm oil industry. It contains large quantity of organic matter in the form of total suspended solids (TSS), volatile suspended solids (VSS), total solids (TS), oil and grease which is the major contribution to the water resources pollution especially rivers or lakes if left untreated. Raw POME has high value of Biochemical Oxygen Demand (BOD) which is more than 30,000 ppm, thus it must be treated before it can be discharged to the water resources. Therefore, this paper presents a new method of POME treatment using microbubbles. Microbubble is selected due to its high oxygen transfer coefficient at a low air flow rate that can give a major impact on reducing the BOD of POME. Thus, microbubble can be a factor on reducing the BOD of POME. The POME sample was collected and handled according to APHA standard. The duration of treatment was carried out for 120 minutes by analysing the BOD at the following time intervals; 0, 30, 60, 90, and 120 minutes with introduction of microbubble. The BOD results were measured using Five- Day Biochemical Oxygen Demand method (APHA 5210 B). The lowest flowrate of microbubbles performed better in reducing the Biochemical Oxygen Demand (BOD) with reduction of 26% of BOD at 60th minutes retention time. It is due to the lowest air flowrate produced the smallest size of microbubble whereas the bubble size is one of the key factors with significant impacts on floatation and mixing that affect aeration process.

Downloads