Comparison of Diesel Engine Performance between a Mechanical Pump and a Common Rail Fuel Injection System Equipped with Real-Time Non-Surfactant Emulsion Fuel Supply System

DOI:

https://doi.org/10.37934/arfmts.91.2.4150Keywords:

Diesel vehicles, commonrail, Emulsion fuel, Non-Surfactant, NOx, smokeAbstract

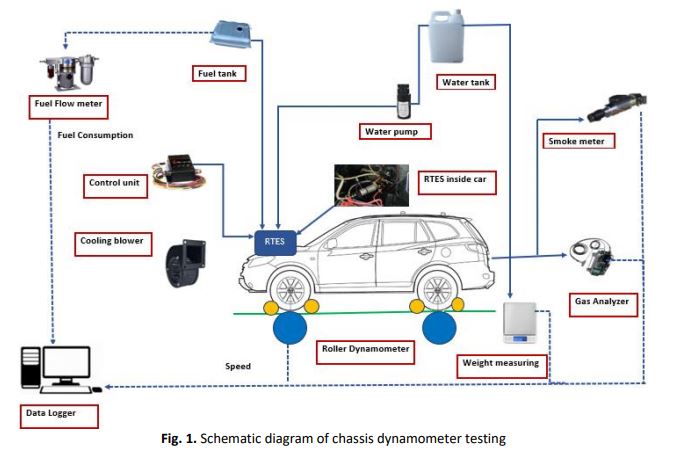

The global focus in emulsion fuels is due to the advantages over conventional diesel fuels. It has the capabilities to simultaneously reduce the emissions of NOx and smoke. It also said to reduce the fuel consumption of diesel engine by significant percentages. However, due to the interdependency on surfactant, emulsion fuel does not seem to be possible as alternative fuel in an economic perspective. This is because of the high market price of the commercial surfactant. Therefore, this research focused on non-surfactant W/D that produced by a system known as Real-Time Non-Surfactant Emulsion Fuel Supply System (RTES). RTES has been applied with the goal of investigating the impact on exhaust emissions and fuel consumption of a mechanical pump fuel injection system diesel vehicle (MP) and a common rail fuel injection system diesel vehicle (CR). A one-ton truck represents as MP (Mechanical Pump) and an SUV represent as CR (Common rail) are the test vehicles for the said research. The non-surfactant W/D with 6.5 wt.% of water produced by the RTES used as the test fuel and named as E6.5. It has been emulsified in the RTES right before being injected into the diesel vehicles. The testing was performed on a chassis dynamometer following the West Virginia University 5-peak cycles. The findings show that the utilization of non-surfactant W/D has increased the fuel consumption by 7.39% for MP and 3.2% for CR respectively as compared with base diesel fuel. NOx, smoke emissions and exhaust temperature have significantly reduced by the MP relative to CR vehicles. Overall, the concept of non-surfactant W/D seems to have implementation potential for reducing harmful emissions from both diesel-powered vehicles.

Downloads