Vulcanization Bonded Natural Rubber-Aluminum by Chemically Modified Graphene Nanoplatelets-Epoxy Adhesive without Primer

DOI:

https://doi.org/10.37934/arfmts.110.1.182199Keywords:

Peel Strength, Graphene Nanoplatelets, Epoxy Adhesive, Engine Mount, Vulcanization BondingAbstract

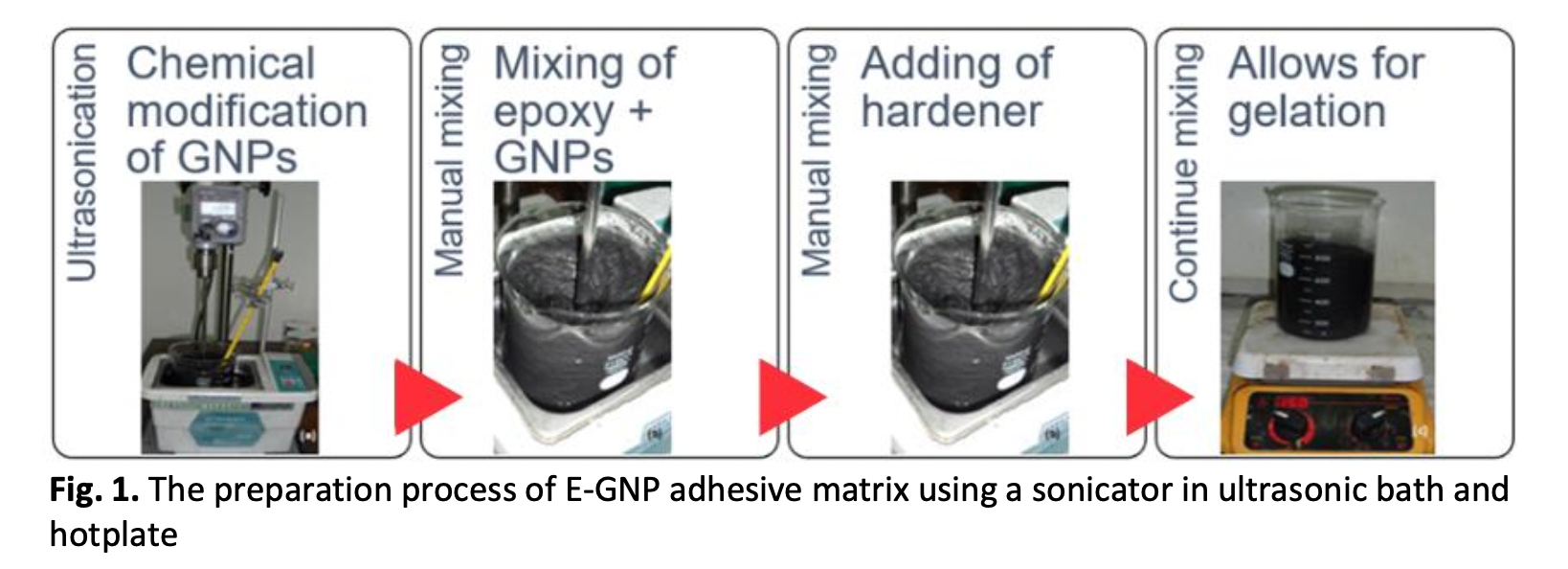

Passive engine mounts have been widely used as the simplest solution to isolate the vibration, noise, and harshness from the engine and chassis for a smooth ride. It is mainly made from rubber and metal, requiring rubber-to-metal bonding. Most studies of rubber-to-metal via adhesive bond report the adhesion properties with the help of a primer. In this study, an adhesive system of graphene nanoplatelets (GNPs) reinforced epoxy resin was investigated for their potential to bond the natural rubber composites (NR) with aluminium alloy (AL-alloy) without any application of primer to assess the GNPs' unique contribution to the adhesion criteria. Chemically treated GNPs were mixed into an epoxy system via an ultrasonication method at 0, 0.5, 3.0, and 7.0 wt% loading variation. The epoxy/GNPs (E-GNP) adhesives were then applied to bond pre-etched Al-alloy sheets with NR composites through the vulcanization bonded. The vulcanization was taken placed in a hot press machine under the temperature of 140°C, a pressure of 100 kg/cm2 for 10 minutes before the samples were subjected to the peel test following ASTM D429. The bonding characteristics were further supported by morphological, compositional, thermal, and structural analyses via Scanning Electron Microscopy, Fourier Transform Infrared Spectroscopy, Differential Scanning Calorimetry, and X-Ray Diffraction. From the results, the E-GNP adhesive system has proven to increase the maximum peel strength of the NR composites-Al alloy by up to 170 % if compared to the control epoxy system. The findings would be a promising technology for improving bonding strength between rubber-metal in diverse applications.

Downloads