Investigation on Standing Wave Thermoacoustic Generator Using DeltaEC

DOI:

https://doi.org/10.37934/arfmts.96.2.5164Keywords:

Thermoacoustic generator, honeycomb celcor ceramic, heat exchangerAbstract

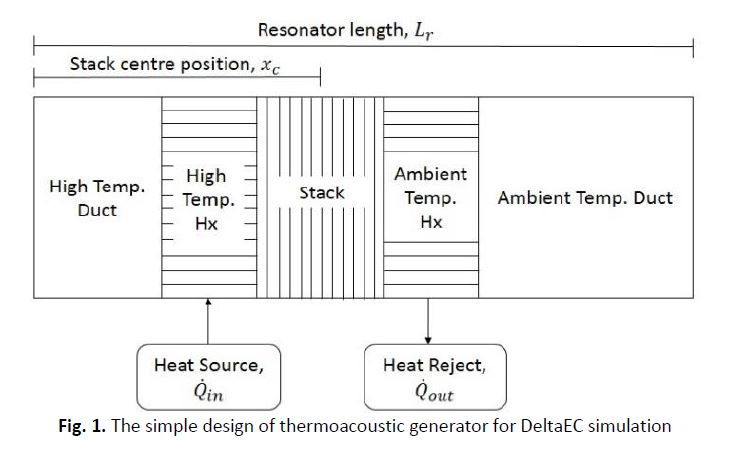

There is currently an urgent demand to reuse waste heat from industrial processes with approaches that require minimal investment and low cost of operation. Thermoacoustic generator (TAG) is a device that converts heat energy into useful work through the use of acoustic wave, porous media (honeycomb ceramic celcor) and heat exchangers that are all enclosed in a custom-defined resonator. This paper reports the basic design of thermoacoustic generator that is tested using a design software known as a Design Environmental for Low-amplitude Thermoacoustic Energy Conversion (DeltaEC). Many studies have highlighted the relationships between the geometry of the stack and the performance of the device. In this study, attention is given on the impact of the length of stack which was found to be the best at a length of 0.6 m when the frequency of the flow is at 127.4 Hz. Performance indicators like the acoustic power and the temperature difference across the stack have been used to analyse the results. The result shows that the highest acoustic power can be achieved when the generator that work with air at an atmospheric pressure is designed with a resonator of 2.14 m long and a stack with a length of 0.6 m. The maximum value for acoustic power is predicted to be as much as 24.01 kW.

Downloads