The Effect of Blended Palm Oil Biodiesel Droplet Properties on Evaporation Characteristics

DOI:

https://doi.org/10.37934/arfmts.112.2.214229Keywords:

Biodiesel, evaporation, heated surface, non-single droplet, single dropletAbstract

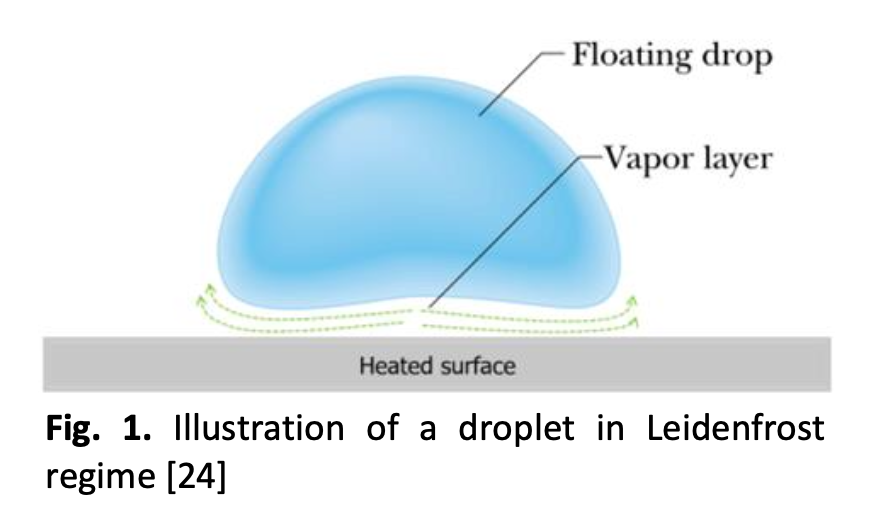

The evaporation characteristics of a single fuel droplet of diesel fuel (DF) and the Malaysian palm oil biodiesel-diesel blend (B10-B50) were studied experimentally. The fuel droplet properties consisted of different ratios of palm oil biodiesel mixtures which could influence the droplet behaviour when impinged on the heated surface. By employing the hot surface deposition test (HSDT) method, the droplets impinging on the heated surface of an aluminum alloy plate were observed to evaluate the droplet's evaporation characteristics including the evaporation lifetime and maximum evaporation point (MEP) of the tested fuels. Furthermore, the deposit’s surface temperature for dry condition (timp=7 seconds) and wet condition (timp=3 seconds) test were also measured during the deposition test. Finally, the deposit development on the heated surface was evaluated through a logarithmic expression of MR/mD = αNDβ. The results showed that the evaporation lifetime of each test fuel decreased with increasing hot plate surface temperature. Furthermore, the MEP was the highest for B30 (380°C), followed by B20 and B40 (375°C), B10 and B50 (365°C), and DF (360°C). In the dry condition test, the recorded average minimum and maximum deposit surface temperatures were observed to be within the range of Td=295°C to Td=325°C for DF and Td=290°C to Td=350°C for B10-B50 fuels. On the other hand, for the wet condition test, the recorded average minimum deposit surface temperatures for both DF and B10-B50 fuels were consistently lower than the hot plate temperature. DF exhibited the most variation, ranging from Td=200°C to Td=300°C, whereas, for B10-B50, the recorded deposit surface temperature was only ranging from Td=150°C to Td=200°C.

Downloads