A Review on Heat Treatment Factor and Precipitations to Improve the Third Generation of Aluminum Lithium Alloys Used in Aeronautic Applications

DOI:

https://doi.org/10.37934/arfmts.95.1.8598Keywords:

Al-Li alloys, heat treatment, strengthening mechanisms, mechanical properties, additive manufacturingAbstract

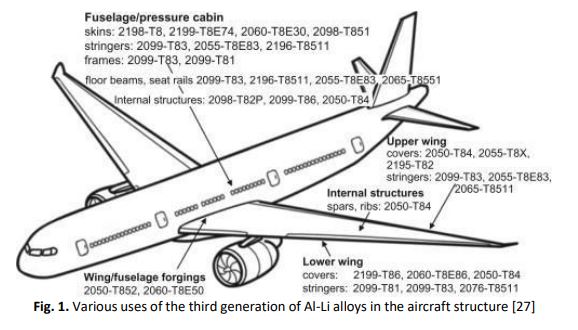

Aluminum lithium (Al-Li) alloys have attracted attention for military applications and aeronautic industry because of their properties especially low density compared to conventional aluminum alloys, the excellent characteristics that are attributed to the lithium addition, and to the different types of precipitations that have a radical effect on mechanical properties of Al-Li alloys. The 3rd generation of Al–Li alloys has been improved to reduce the defects of previous generations by combining the density reduction with high strength. This paper provides a review on the third generation of Al-Li alloys and its applications, the different types of precipitations, heat treatments and their influence on mechanical properties and grain refinement. Most early studies that have been realized by researchers over the last few years on aluminum lithium alloys for additive manufacturing are also reviewed in this paper.

Downloads