Comparison of Drag Reduction Effect on Barge Model Ship Using Ultrafine Bubble and Microbubble Injection

DOI:

https://doi.org/10.37934/arfmts.96.2.134143Keywords:

Energy efficiency, drag reduction, microbubble, ultrafine bubble, injection, optimumAbstract

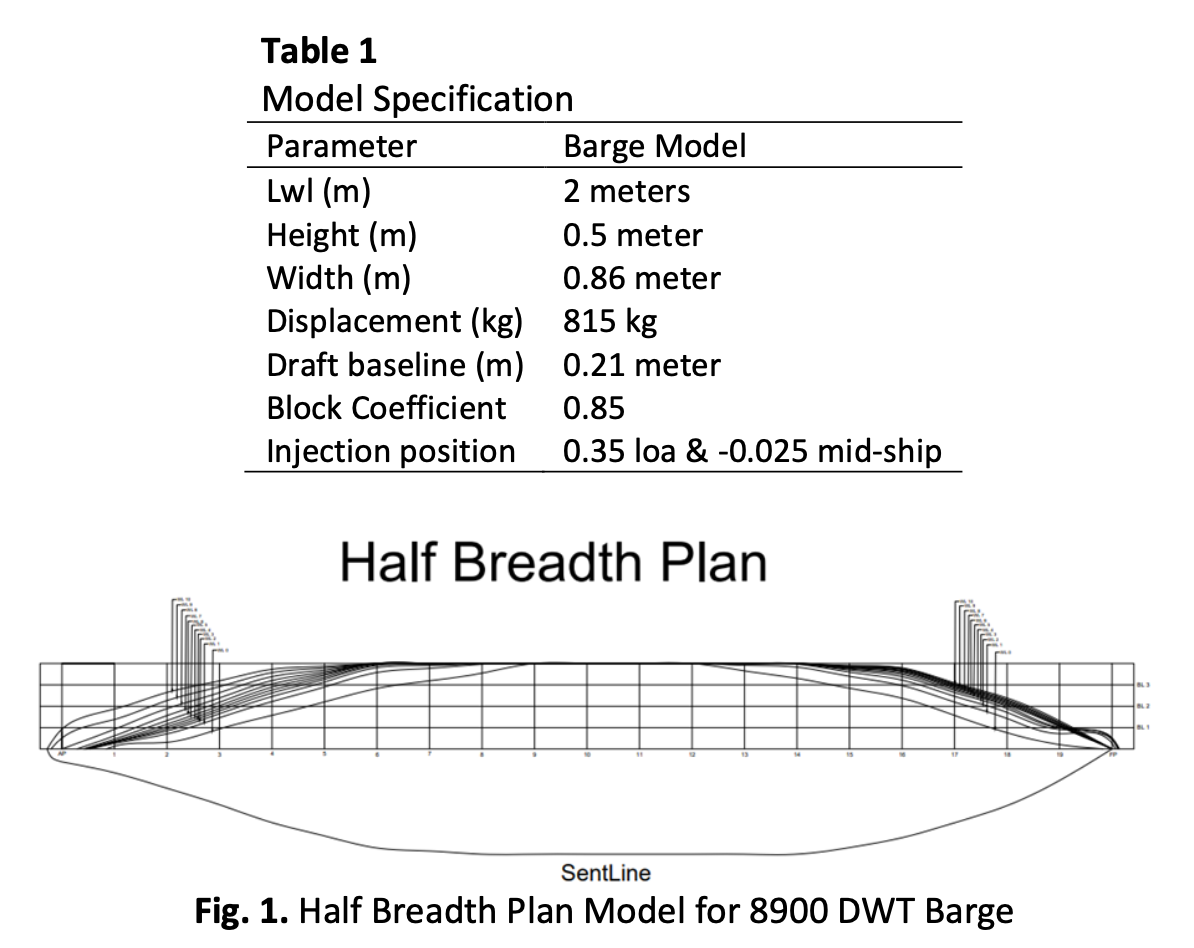

Energy efficiency is a global goal in the fight against global warming. Research on reducing drag is one of the ways to improve energy efficiency. The research method used is the injection of micro-sized bubbles and ultra-fine bubbles used in the barge ship model. Microbubble Drag Reduction (MBDR) and Ultrafine Bubble Drag Reduction (UFBDR) are two methods that can play an essential role in reducing drag on the surface of the ship's hull. Factors that can affect the effectiveness of these methods are the injection ratio, location, and coefficient of drag produced by both methods. The injection method discussed the use of the method, which was reviewed on a 2-meter towing tank and compared the two injection methods. The results provided by this research are to determine the injection ratio and the optimum injection location on the model ship and compare the effect of reducing drag and drag coefficient. The increases total resistance reduction of 6.87% compared to the reduction in resistance by microbubble injection.

Downloads