Nanobubbles Interaction on Flat Plates Affecting Volumetric Gas Flux and Local Void Ratio

Keywords:

Nanobubble, boundary layer, multiplier constants, volumetric flux, plate spacingAbstract

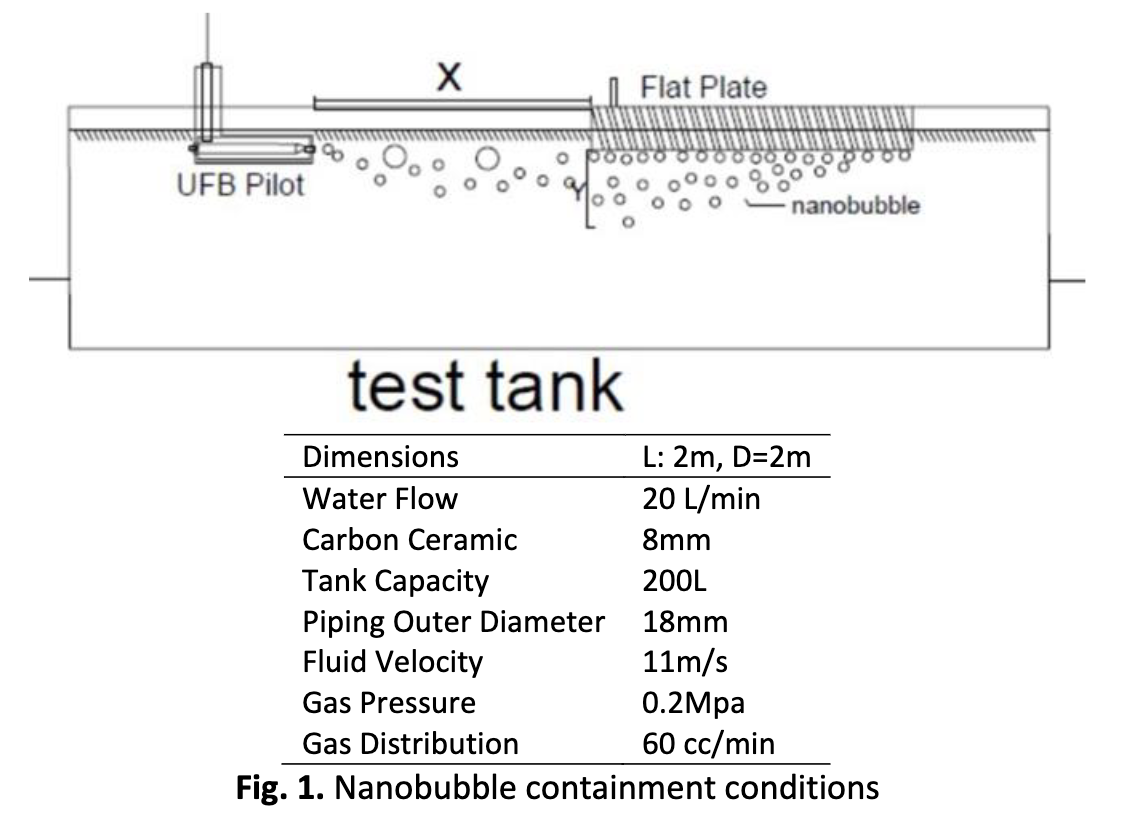

A pipe has a great significance to deposit fluid from one place to another. Distributing solution to the engine, cooling system, and ballast system are crucial for a ship to operate correctly. Drag is one of the obstructions in the internal flow of the pipeline, restricting the fluid to stream smoothly. Majority studies use numerous methods to reduce the effect, such as using microbubble, minimizing the length of pipe installation, and injection of nanobubble. Bubble drag reduction is one of the most modern methods; the previous study showed that 2mm bubble size has a lot less beneficial for decreasing drag than a 40 µm bubble at the same fluid velocity. Based on previous research, this study will show the impact of nanobubble in reducing drag produced by a carbon-ceramic nozzle. This research studies the nanobubble influence explicitly by using diverge types of conditions such as various injection distance, several areas of the plates, and analyze the utilization of nanobubble and microbubble within the boundary layer. The boundary layer investigated by circumscribing volumetric gas flux and gas flux injection and then scrutinize the findings providing a local void ratio. Research towards the boundary layer used a shred of photographic evidence, examine by using Jimage processing to view the distance between the exterior of the plates and the current generated by nanobubble injection. Flux ratio created from the resulting multiplier constant, which is the ß factor that expresses the effectiveness of the nanobubble drag reduction technique. Finally, the result obtained that nanobubble is 0.82912 times more efficient than using microbubble with an injection range of 80mm and a local void ratio of 2.1.

Downloads