Rheological Properties of Natural Fiber Reinforced Thermoplastic Composite for Fused Deposition Modeling (FDM): A Short Review

DOI:

https://doi.org/10.37934/arfmts.98.2.157164Keywords:

Fused Deposition Modeling (FDM), rheological properties, natural fibers, polymer, compositesAbstract

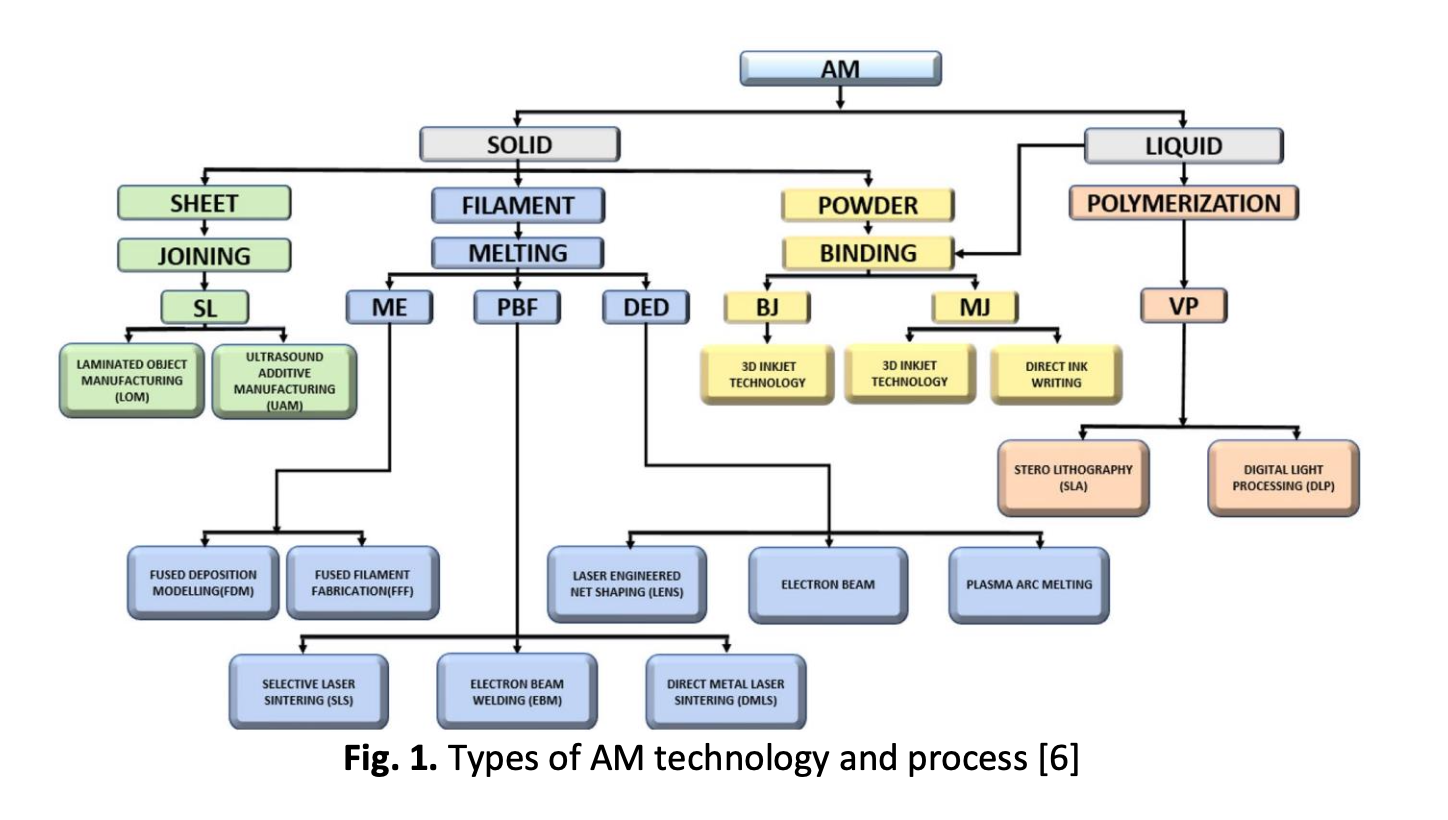

In the development and manufacturing industries, fused deposition modeling (FDM) receives the greatest attention. It is the most important additive manufacturing (AM) technique, which refers to the process of depositing multiple layers of material in a computer-controlled environment to form a three-dimensional product. Research is presently focusing on the development of 3D printed bio-composite polymers with improved performance. Many studies on the development of new composite materials using natural fiber as a feedstock filament for FDM have recently been published. As a result, conducting a rheology characteristics analysis of new composite materials made from natural resources is required. Its major purpose is to describe the flow behavior of the fiber composite material and determine the optimal melting temperature for the extrusion process of producing wire filament. Thus, this paper focuses on rheological properties of fiber-reinforced thermoplastic composite for FDM.

Downloads