Thermal Properties of Wood Dust Fibre and Recycled Polypropylene (r-WoPPc) for Development of Thermoplastic Composites Filaments of Fused Deposition Modeling

DOI:

https://doi.org/10.37934/arfmts.96.2.4250Keywords:

Wood dust fibre, recycle polypropylene, composite filaments, Fused Deposition ModelingAbstract

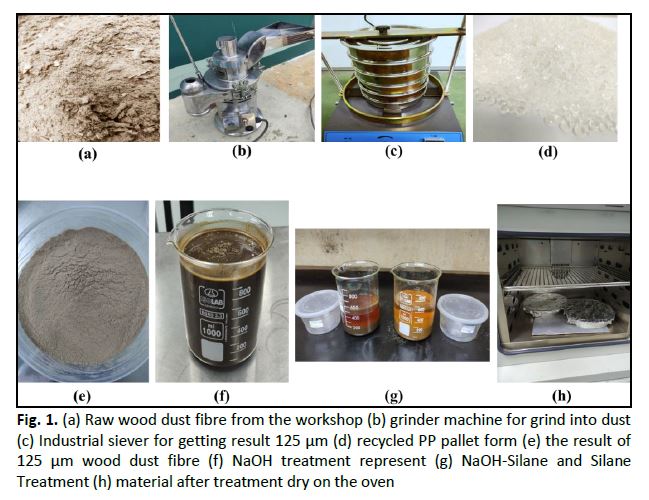

The thermal behaviour of filament materials is one of the most important characteristics to study to produce quality filament since the FDM process strongly relies on heating operations such as mixing and printing. To develop composite filament FDM using recycled polypropylene and wood dust fibre (r-WoPPc), the thermal properties of these recycled materials were investigated. Wood dust and recycled PP are by-products of the furniture and plastics industries, and their thermal characteristics may change during manufacturing. Furthermore, wood dust is typically subjected to several cleaning and treatment processes to have a cleaner and impurity-free dust as well as better adhesion with the recycled PP matrix, which both processes may affect its thermal properties. Therefore, TGA and DSC analyses are conducted to ensure its thermal properties before developing the filament. Untreated, NaOH and silane treated wood dust and recycled PP was subjected to TGA and DSC analyses. Wood dust treated with silane had the highest combustion resistance at 372°C compared to untreated wood dust at 360°C and NaOH treated at 320°C. Meanwhile, DSC analysis of recycled PP indicated that it melted at 167°C, which was used to establish the filament extrusion and printing temperatures. In a conclusion, these studies provided a point of reference for determining filament extrusion and printing temperatures.

Downloads