Thermal and Durability Properties of Sustainable Green Lightweight Foamed Concrete Incorporating Eco-Friendly Sugarcane Fibre

DOI:

https://doi.org/10.37934/arfmts.94.1.6078Keywords:

Lightweight foamed concrete, thermal conductivity, diffusivity, specific heat capacity, water absorptionAbstract

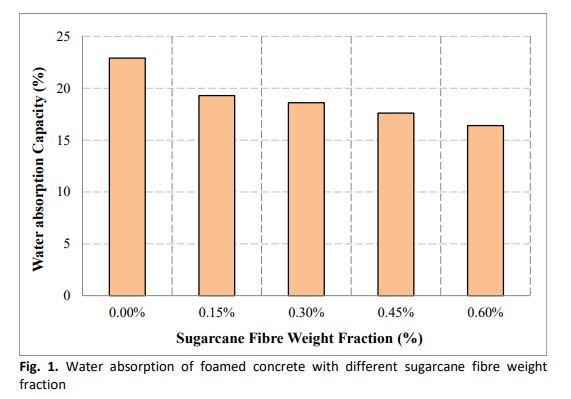

Efforts to modify cement-based mixtures have always enticed the interest of researchers. Lightweight foamed concrete is immensely porous, and its properties diminish with increasing in the number of pores. To enhance its properties, the solid matrix of LFC can be attuned by integrating numerous natural fibres. The influence of eco-friendly sugarcane fibre in LFC was not investigated before in the current body of knowledge. Hence, there is some ambiguity considering the mechanism by which and the extent to which the sugarcane fibre can influence LFC properties. Therefore, this study concentrates on distinguishing the potential use of sugarcane fibre into lightweight foamed concrete. This study aims to determine the durability and thermal properties of LFC with the addition of sugarcane fibre. Low density of 800kg/m3 were cast and tested. Different weight fractions of sugarcane fibre of 0.15%, 0.30%, 0.45% and 0.60% were used. For durability properties, four parameters were appraised such as water absorption capacity, porosity, drying shrinkage, ultrasonic pulse velocity. While for thermal properties were assessed which were thermal conductivity, thermal diffusivity and specific heat capacity. Protein-based foaming agent Noraite PA-1 was utilized to produce the desirable density of LFC. To get the comparable results, the water to cement ratio was fixed to 0.45 while the cement to sand ratio constant at 1:1.5. The results had indicated that the addition of 0.45% of sugarcane fibre gave the optimum results for all the durability and thermal properties considered in this research. At 0.45% weight fraction of SF, the fibres and the cementitious matrix achieved maximum compaction, which stemmed in excellent mix homogeneity. Beyond the optimum level of sugarcane fibre inclusion, agglomeration and the non-uniform dispersion of fibres was observed, which led to decrease in entire durability and thermal properties appraised.

Downloads