Determination of Thermal Properties of Lightweight Cellular Mortar (LCM) of Different Density through Guarded Hot Plate Method

Keywords:

Thermal conductivity, mortar, lightweight cellular concrete, oid size, porosityAbstract

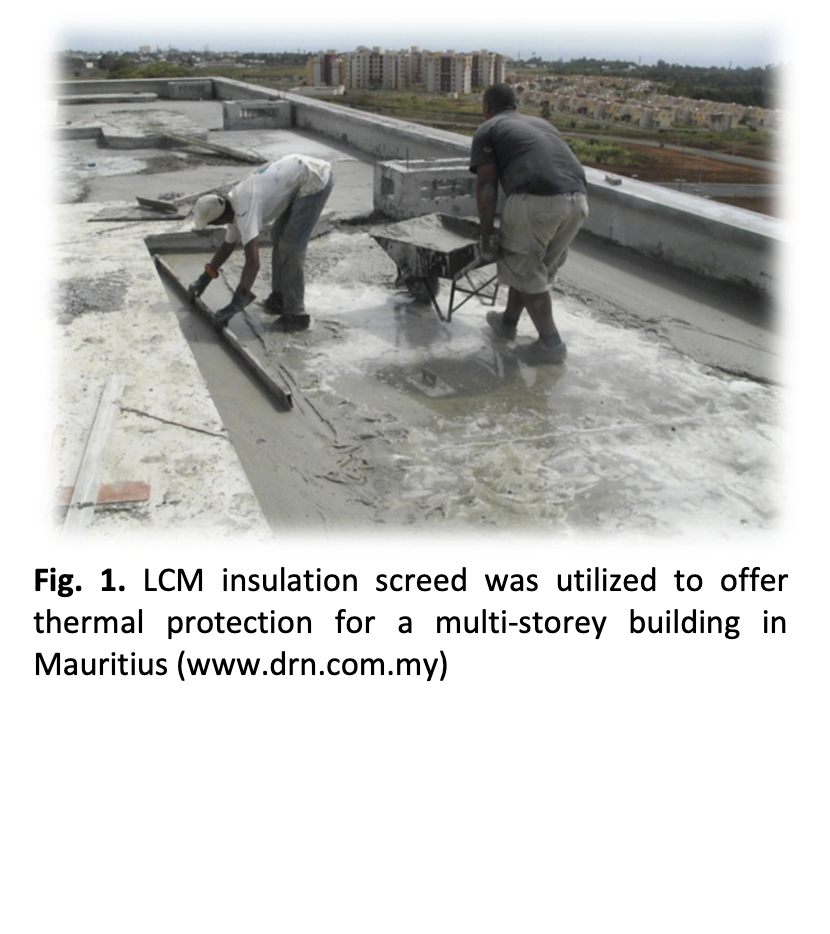

Currently, the construction industry in Malaysia has shown substantial awareness in employing lightweight cellular mortar (LCM) as a building material. The main advantages of LCM are its outstanding thermal properties, low density, excellent fire resistance performance, exceptional impact resistance and worthy freeze thaw resistance. The application of low thermal conductivity building materials is significant to reduce heat gain through the envelope into the building in hot climate country like Malaysia. Hence, the aim of this study is to determine the effective thermal conductivity of LCM of various densities through Guarded Hot Plate Method. The densities were ranging from 550, 650, 750, 850 and 950 kg/m3 with constant cement-sand ratio of 2:1 and water-cement ratio of 0.45. This study focused on the effects of density, porosity and mortar bubble size on thermal conductivity of LFC. Guarded Hot Plate Method was used to attain the thermal conductivity of LCM of various densities. The porosity value of LCM was determined through the Vacuum Saturation Apparatus. In order to scrutinize the effect of mortar bubble size on thermal conductivity of LCM, bubble size measurements were made under a microscope with a magnification of 50x. From the experimental results, it had shown that lower density LCM decodes to lower thermal conductivity. For instance, the thermal conductivity for LCM reduced from 0.30 to 0.24W/mK and further reduced to 0.19W/mK for corresponding densities of 950, 750 and 550 kg/m3, respectively. The density of LCM is controlled by the porosity where lower density LCM specifies higher porosity. The study also revealed that the dominant void size rises as the LCM density declines due to the higher amount of foam used. For example, from a microscopic analysis of the internal images of the three densities of LCM, the dominant void size of the 550, 750 and 950 kg/m3 density LCM has been determined as 0.76mm, 0.66mm and 0.55mm in that order. Hence, thermal conductivity changes significantly with the porosity of LCM because air is the poorest conductor compared to solid and liquid due to its molecular structure. From the results obtained, it can be concluded that LCM has very low thermal conductivity, making it a suitable material for building use as insulating or fire resisting material due to its porous internal structure.

Downloads