Investigation of Sloshing in Different Tank Shapes using Smoothed Particle Hydrodynamics

DOI:

https://doi.org/10.37934/cfdl.15.12.1933Keywords:

Tank shape, sloshing, SPH, dynamic pressure, hydrodynamic forceAbstract

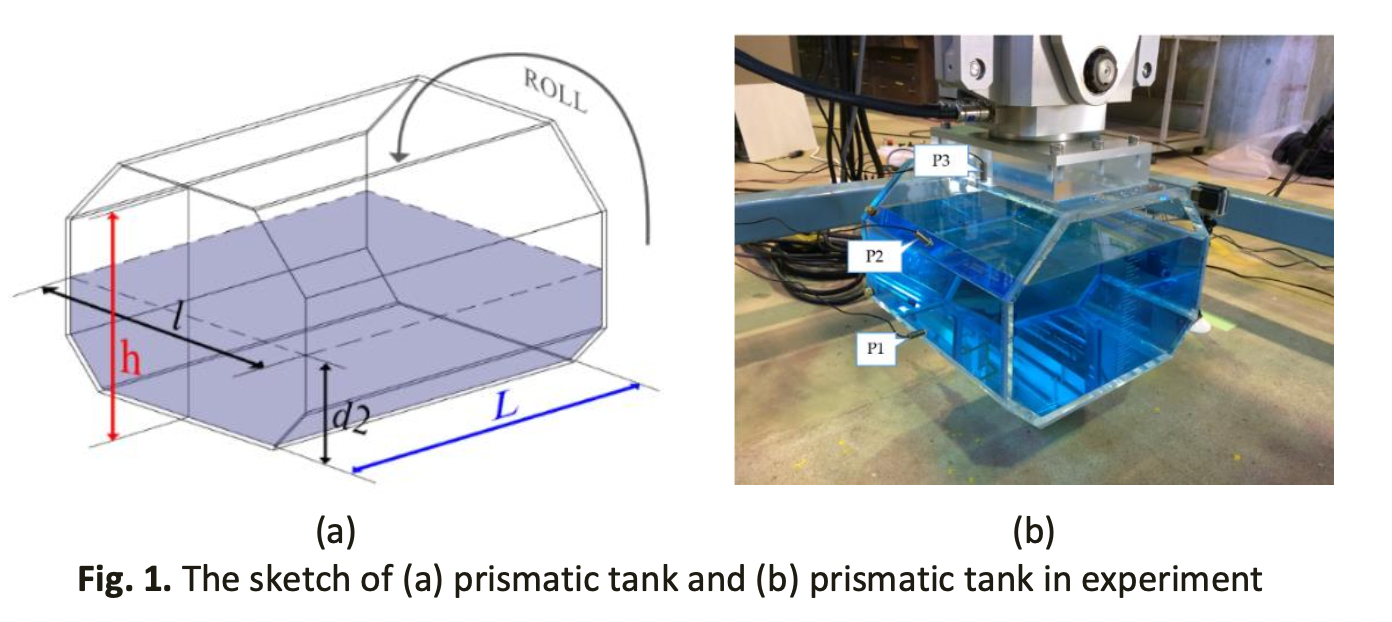

Sloshing is the violent motion of a resonant fluid in a moving tank; when the fluid moves and interacts with the tank, the dynamic pressure from such an interaction can cause large fluid deformations with tank walls. In this study, a 3D numerical simulation of sloshing was carried out with five variations of the tank model, i.e., prismatic, rectangular, tube, spherical, and the new model tank with a filling ratio of 25% and 50%. Forced oscillation motion in a roll used frequencies 1.04 Hz and 1.34 Hz. The amplitude of movement was 8.66°. One pressure sensor was used to measure dynamic pressure in the mid of the tank. Because sloshing deals with large deformation and discontinuities, the particle method was suitable for the application. This study used smoothed particle hydrodynamics based on weakly compressible SPH (WCSPH). SPH is a Lagrangian meshless method known as mesh-free computational fluid dynamics. Open-source SPH solver version 5.0 was used to reproduce sloshing in different tank shapes; in addition, advanced visualization was performed using the VisualSPHysics add-on in Blender version 2.92. The sloshing visualization is more realistic and attractive than conventional SPH post-processing. The results of this study indicate that different tank shapes influence reducing the value of dynamic pressure and hydrodynamic force. It is found that a practical tank shape is a tube tank and a new model tank with a reduced dynamic pressure value of 9% and 11% and a reduced hydrodynamic force value of 36% and 48%.

Downloads

References

Monaghan, J.J. “Simulating Free Surface Flows with SPH.” Journal of Computational Physics 110, no. 2 (1994): 399–406. https://doi.org/10.1006/jcph.1994.1034

Monaghan, J.J., and A. Kocharyan. “SPH Simulation of Multi-Phase Flow.” Computer Physics Communications 87, no. 1–2 (May 2, 1995): 225–35. https://doi.org/10.1016/0010-4655(94)00174-Z

Green, Mashy D., and Joaquim Peiró. “Long Duration SPH Simulations of Sloshing in Tanks with a Low Fill Ratio and High Stretching.” Computers & Fluids 174 (September 16, 2018): 179–99. https://doi.org/10.1016/j.compfluid.2018.07.006

Green, Mashy D., Yipeng Zhou, José M. Dominguez, Moncho G. Gesteira, and Joaquim Peiró. “Smooth Particle Hydrodynamics Simulations of Long-Duration Violent Three-Dimensional Sloshing in Tanks.” Ocean Engineering 229 (2021): 108925. https://doi.org/10.1016/j.oceaneng.2021.108925

Pilloton, C, A Bardazzi, A Colagrossi, and S Marrone. “SPH Method for Long-Time Simulations of Sloshing Flows in LNG Tanks.” European Journal of Mechanics - B/Fluids 93 (2022): 65–92. https://doi.org/https://doi.org/10.1016/j.euromechflu.2022.01.002

Yang, Xi, Zhifan Zhang, Guiyong Zhang, Song Feng, and Zhe Sun. “Simulating Multi-Phase Sloshing Flows with the SPH Method.” Applied Ocean Research 118 (2022): 102989. https://doi.org/https://doi.org/10.1016/j.apor.2021.102989

Trimulyono, Andi, Samuel, and Muhammad Iqbal. “Sloshing Simulation of Single-Phase and Two-Phase SPH Using DualSPHysics.” Kapal: Jurnal Ilmu Pengetahuan Dan Teknologi Kelautan 17, no. 2 (2020): 50–57. https://doi.org/10.14710/kapal.v17i2.27892

Trimulyono, A., D. Chrismianto, Samuel Samuel, and M. H. Aslami. “Single-Phase and Two-Phase Smoothed Particle Hydrodynamics for Sloshing in the Low Filling Ratio of the Prismatic Tank.” International Journal of Engineering, Transactions B: Applications 34, no. 5 (2021): 1345–51. https://doi.org/10.5829/ije.2021.34.05b.30

Ren, Yaru, Abbas Khayyer, Pengzhi Lin, and Xiangyu Hu. “Numerical Modeling of Sloshing Flow Interaction with an Elastic Baffle Using SPHinXsys.” Ocean Engineering 267 (2023): 113110. https://doi.org/10.1016/j.oceaneng.2022.113110

Trimulyono, Andi, Atthariq Haikal, Chrismianto Deddy, and Samuel Samuel. “Investigation of Sloshing in The Prismatic Tank With Vertical And T-Shape Baffles.” Brodogradnja 73, no. 2 (2022): 43–58. https://doi.org/10.21278/brod73203

Trimulyono, Andi, Deddy Chrismianto, Haikal Atthariq, and Samuel. “Numerical Simulation Low Filling Ratio of Sway Sloshing in the Prismatic Tank Using Smoothed Particle Hydrodynamics.” CFD Letters 14, no. 7 (2022): 113–23. https://doi.org/10.37934/cfdl.14.7.113123

Liu, Zhan, Hong Chen, Qiang Chen, and Liubiao Chen. “Numerical Study on Thermodynamic Performance in a Cryogenic Fuel Storage Tank Under External Sloshing Excitation.” International Journal of Aeronautical and Space Sciences 22, no. 5 (2021): 1062–74. https://doi.org/10.1007/s42405-021-00385-9

Liu, Zhan, Kaifeng Yuan, Yuanliang Liu, Martin Andersson, and Yanzhong Li. “Fluid Sloshing Hydrodynamics in a Cryogenic Fuel Storage Tank under Different Order Natural Frequencies.” Journal of Energy Storage 52, no. PA (2022): 104830. https://doi.org/10.1016/j.est.2022.104830

Liu, Zhan, Kaifeng Yuan, Yuanliang Liu, Yinan Qiu, and Gang Lei. “Fluid Sloshing Thermo-Mechanical Characteristic in a Cryogenic Fuel Storage Tank under Different Gravity Acceleration Levels.” International Journal of Hydrogen Energy 47, no. 59 (2022): 25007–21. https://doi.org/10.1016/j.ijhydene.2022.05.243

Subramaniam, Thineshwaran, and Mohammad Rasidi Rasani. “Pulsatile CFD Numerical Simulation to Investigate the Effect of Various Degree and Position of Stenosis on Carotid Artery Hemodynamics.” Journal of Advanced Research in Applied Sciences and Engineering Technology 26, no. 2 (2022): 29–40. https://doi.org/10.37934/araset.26.2.2940

Noh, Arina Mohd, Sohif Mat, and Mohd Hafidz Ruslan. “CFD Simulation of Temperature and Air Flow Distribution inside Industrial Scale Solar Dryer.” Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 45, no. 1 (2018): 156–64.

Adanta, Dendy, Mochammad Malik Ibrahim, Dewi Puspita Sari, Imam Syofii, and Muhammad Amsal Ade Saputra. “Application of the Grid Convergency Index Method and Courant Number Analysis for Propeller Turbine Simulation.” Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 96, no. 2 (2022): 33–41. https://doi.org/10.37934/arfmts.96.2.3341

Musa, Solihin, Nor Azwadi Che Sidik, Siti Nurul Akmal Yusof, Teknologi Malaysia, Jalan Sultan Yahya Petra, and Kuala Lumpur. “Analysis of Internal Flow in Bag Filter by Different Inlet Angle.” Journal of Advanced Research in Numerical Heat Transfer 3, no. 1 (2020): 12–24. https://www.akademiabaru.com/submit/index.php/arnht/article/view/1365

Trimulyono, Andi, Hirotada Hashimoto, and Akihiko Matsuda. “Experimental Validation of Single- and Two-Phase Smoothed Particle Hydrodynamics on Sloshing in a Prismatic Tank.” Journal of Marine Science and Engineering 7, no. 8 (2019). https://doi.org/10.3390/jmse7080247

Domínguez, J M, G Fourtakas, C Altomare, R B Canelas, A Tafuni, O García-Feal, I Martínez-Estévez, et al. “DualSPHysics: From Fluid Dynamics to Multiphysics Problems.” Computational Particle Mechanics 9, no. 5 (2022): 867–95. https://doi.org/10.1007/s40571-021-00404-2

Crespo, A.J.C., J.M. Domínguez, B.D. Rogers, M. Gómez-Gesteira, S. Longshaw, R. Canelas, R. Vacondio, A. Barreiro, and O. García-Feal. “DualSPHysics: Open-Source Parallel CFD Solver Based on Smoothed Particle Hydrodynamics (SPH).” Computer Physics Communications 187 (2015): 204–16. https://doi.org/10.1016/j.cpc.2014.10.00

García-Feal, O, A J C Crespo, and M Gómez-Gesteira. “VisualSPHysics: Advanced Fluid Visualization for SPH Models.” Computational Particle Mechanics 9, no. 5 (2022): 897–910. https://doi.org/10.1007/s40571-020-00386-7

Liu, G. R, Liu MB. Smoothed Particle Hydrodynamics: A Meshfree Particle Method. World Scientific Publishing Company; 2003. https://doi.org/10.1142/9789812564405

Molteni D, Colagrossi A. A simple procedure to improve the pressure evaluation in hydrodynamic context using the SPH. Comput Phys Commun 2009;180:861–72. https://doi.org/10.1016/j.cpc.2008.12.004

Crespo AJC, Gomez-Gesteira M, Dalrymple RA. Boundary Conditions Generated by Dynamic Particles in SPH Methods. Comput Mater Contin 2007;5:173–84

English A, Domínguez JM, Vacondio R, Crespo AJC, Stansby PK, Lind SJ, et al. Modified dynamic boundary conditions (mDBC) for general-purpose smoothed particle hydrodynamics (SPH): application to tank sloshing, dam break and fish pass problems. Comput Part Mech 2022;9:1–15. https://doi.org/10.1007/s40571-021-00403-3