A Numerical Comparison of 2D and 3D CFD Modelling for Contraction and Expansion Geometries with an Emphasis on Solid Particles Erosion

DOI:

https://doi.org/10.37934/cfdl.16.6.157168Keywords:

Contraction expansion, 2D Vs 3D, Erosion, Particles trackingAbstract

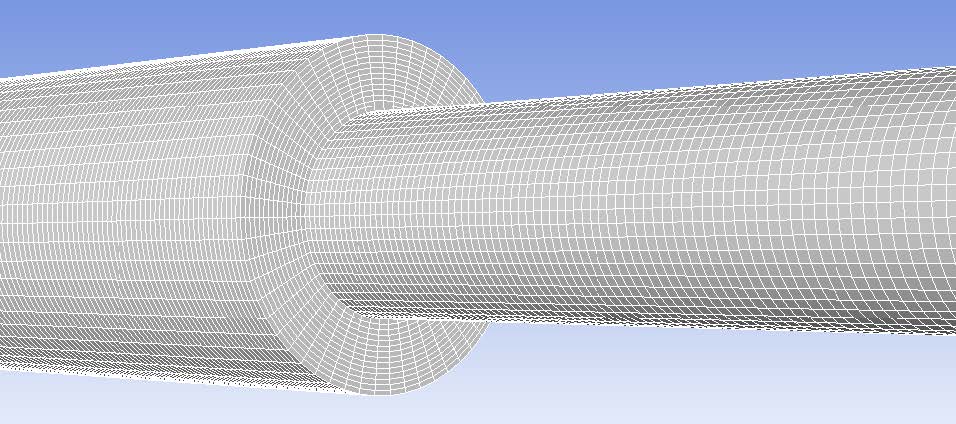

In this study, erosion patterns and magnitude are compared between the outputs of 2D and 3D CFD models in contraction and expansion geometries. ANSYS Fluent software was used to model a circular cross-section geometry with a contraction and the results were compared to published experimental data. The simulation findings showed that there is good agreement between the 2D and 3D CFD models and the experimental data in terms of fluid flow properties such as velocity profiles and magnitude. It also demonstrated that the 2D and 3D CFD models' representations of erosion patterns and magnitudes are equivalent. The 3D CFD simulations were able to provide more information than the 2D CFD simulations, particularly in terms of erosion distribution over the entire geometry.

Downloads

References

Abdulla, Akar. "Estimating erosion in oil and gas pipe line due to sand presence." (2011).

Xu, Yan, Zunce Wang, Sen Li, Fengxia Lv, Yuejuan Yan, and Houzhen Wen. "Analysis of Erosion and Failure in the Sudden Expansion Fracturing Tubing of Deep Gas Wells." In International Conference on Offshore Mechanics and Arctic Engineering, vol. 49149, pp. 293-299. 2010. https://doi.org/10.1115/OMAE2010-21049

Cheng, Jiarui, Yihua Dou, Jiding Zhang, Ningsheng Zhang, Zhen Li, and Zhiguo Wang. "Experimental Study on Particle Erosion Failure of Abrupt Pipe Contraction in Hydraulic Fracturing." Journal of Failure Analysis and Prevention 18 (2018): 382-391. https://doi.org/10.1007/s11668-018-0409-5

Duarte, Carlos Antonio Ribeiro, and Francisco José de Souza. "Dynamic mesh approaches for eroded shape predictions." Wear 484 (2021): 203438. https://doi.org/10.1016/j.wear.2020.203438

Darihaki, Farzin, Ebrahim Hajidavalloo, Amir Ghasemzadeh, and Gholam Abbas Safian. "A localized sand erosion prediction approach for multiphase flow in wells: application for sudden-expansions." Particulate Science and Technology 39, no. 8 (2021): 954-970. https://doi.org/10.1080/02726351.2021.1871990

Li, Qi. "Erosion Prediction on Contractions and Expansions Based on Computational Fluid Dynamics (CFD)." PhD diss., University of Tulsa, 2015.

Zhang, Jun, Farzin Darihaki, Yeshwanthraj Rajkumar, Soroor Karimi, and Siamack A. Shirazi. "Erosion in Sudden Contractions and Expansions." In NACE CORROSION, pp. NACE-2019. NACE, 2019. https://doi.org/10.1016/j.wear.2019.01.106

Darihaki, Farzin, Jun Zhang, and Siamack A. Shirazi. "Solid particle erosion in gradual contraction geometry for a gas-solid system." Wear 426 (2019): 643-651. https://doi.org/10.1016/j.wear.2019.01.106

Agrawal, Madhusuden, Samir Khanna, Ardjan Kopliku, and Tim Lockett. "Prediction of sand erosion in CFD with dynamically deforming pipe geometry and implementing proper treatment of turbulence dispersion in particle tracking." Wear 426 (2019): 596-604. https://doi.org/10.1016/j.wear.2019.01.018

Prasad, S. S., G. Satish, and G. Panduranga. "Comparison of Flow Analysis through Sudden Contraction and Enlargement of Pipes by Providing Smooth Corners." Int. J. Eng. Trends Technol 25 (2015): 205-211. https://doi.org/10.14445/22315381/IJETT-V25P238

Darihaki, Farzin, Ebrahim Hajidavalloo, Amir Ghasemzadeh, and Gholam Abbas Safian. "Erosion prediction for slurry flow in choke geometry." Wear 372 (2017): 42-53. https://doi.org/10.1016/j.wear.2016.12.008

Tsai, Chien-Hsiung, Han-Taw Chen, Yao-Nan Wang, Che-Hsin Lin, and Lung-Ming Fu. "Capabilities and limitations of 2-dimensional and 3-dimensional numerical methods in modeling the fluid flow in sudden expansion microchannels." Microfluidics and Nanofluidics 3 (2007): 13-18. https://doi.org/10.1007/s10404-006-0099-2

Li, Tingwen, Sreekanth Pannala, and Mehrdad Shahnam. “2D versus 3D CFD Simulations of Circulating Fluidized Bed Risers.” In Multiphase Flow Workshop, 2012. https://doi.org/10.1016/j.powtec.2014.04.008

Upadhyay, Mukesh, Myung Won Seo, Parlikkad Rajan Naren, Jong-Ho Park, Thanh Dang Binh Nguyen, Kashif Rashid, and Hankwon Lim. "Experiment and multiphase CFD simulation of gas-solid flow in a CFB reactor at various operating conditions: Assessing the performance of 2D and 3D simulations." Korean Journal of Chemical Engineering 37 (2020): 2094-2103. https://doi.org/10.1007/s11814-020-0646-7

Cammarata, Luca, Paola Lettieri, Giorgio DM Micale, and Derek Colman. "2D and 3D CFD simulations of bubbling fluidized beds using Eulerian-Eulerian models." International Journal of Chemical Reactor Engineering 1, no. 1 (2003). https://doi.org/10.2202/1542-6580.1083

Salehi, M. A., and R. Rahimi. "COMPARISON BETWEEN 2D AND 3D TRANSIENT FLOW SIMULATION OF GAS–LIQUID DYNAMICS IN TWO-PHASE CYLINDRICAL BUBBLE COLUMN REACTORS BY CFD." Int. J. Chem. Sci. 6 (2009): 857-872.

Bullen, P. R., D. J. Cheeseman, and L. A. Hussain. "A study of turbulent flow in pipe contractions." Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 210, no. 3 (1996): 171-180. https://doi.org/10.1243/PIME_PROC_1996_210_312_02