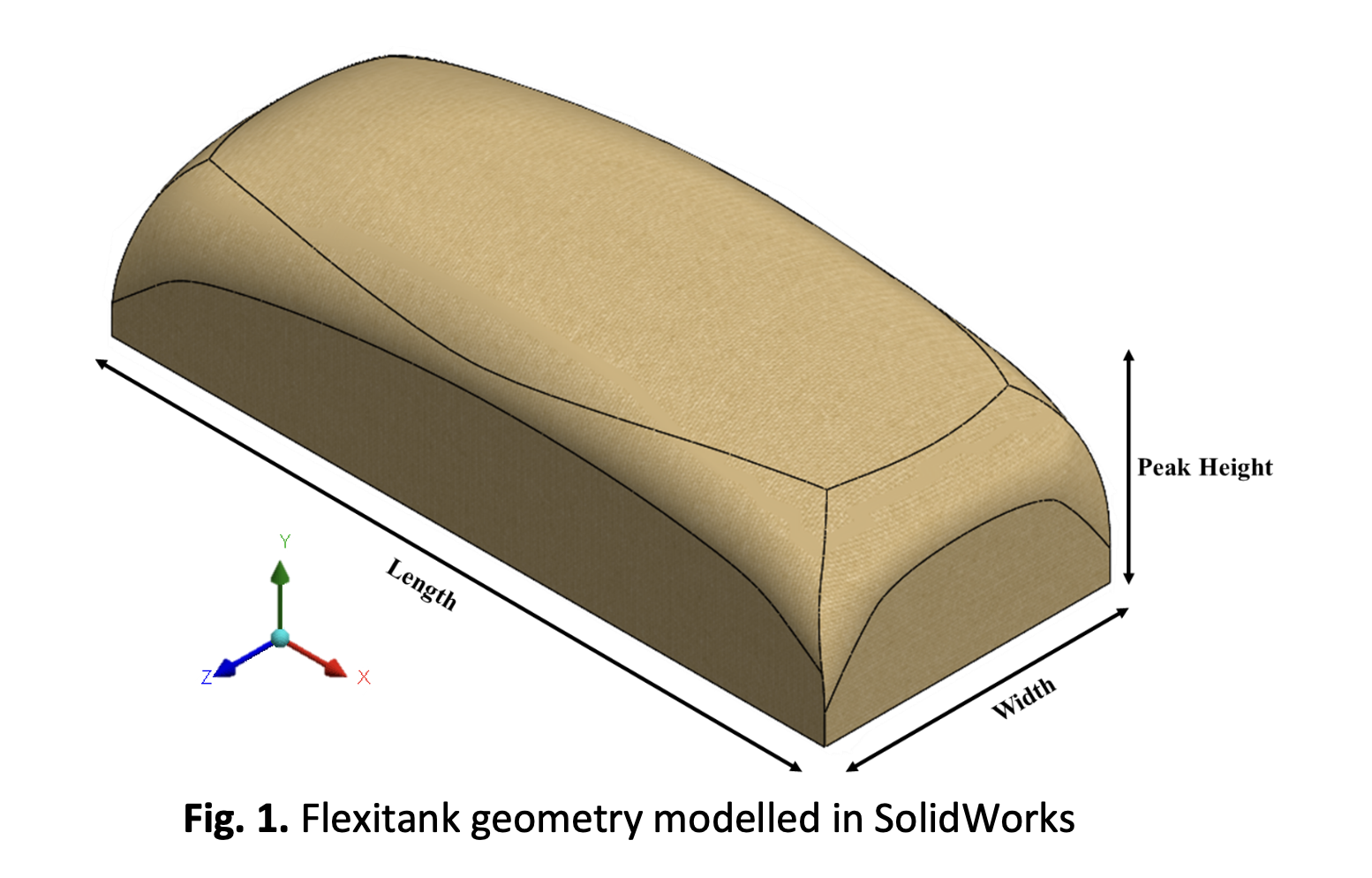

CFD Analysis on Different Filling Volume Capacity and Fluid Density for Flexitank Application

DOI:

https://doi.org/10.37934/cfdl.15.1.115126Keywords:

Bulk Liquid, Transportation, Sloshing, Computational Fluid Dynamics (CFD), Fluid-Structure Interaction (FSI), Flexitank, HydrodynamicsAbstract

When it comes to the structural design of flexitanks used for freight transportation, liquid sloshing is a crucial subject of concern. However, with consideration of the flexitank shape, there is no specific capacity value that can be used as a guide for filling the liquid inside it. This phenomenon may cause a high-pressure impact on the flexitank, resulting in a leakage on the LLDPE package. One of the solutions to reduce the frequency of leaks occurred is to fill up the acceptable volume based on hydrodynamics performance. Therefore, the purpose of this paper is to investigate, using commercial computational fluid dynamics (CFD) software, the hydrodynamic performance of various flexitank filling volume capacities based on different liquid densities. This is evaluated by comparing the hydrodynamics study for filling capacities that are 1%, 2%, and 3% higher than the rated capacity for flexitanks that has been suggested by the Container Owner Association (COA). Due to the flexitanks thin walls, it is important to consider the impacts of fluid-structure interaction (FSI). To do this, a partitioned FSI approach is used by coupling the CFD and FEA solvers for this multi-physics issue. The main standpoint of FSI is that fluid forces are applied to structures, causing deformation. Hydrodynamic parameters such as structural deformation on flexitank, von-mises stress and von-mises strain were used to identify the suitable filling capacity for three different: water, latex, and crude palm oil, as these liquids are commonly used for flexitank. The results indicate that varying the liquid filling capacity affected the hydrodynamic performance of the flexitank. Following that, increasing the flexitank filled with water by 3% and increasing the flexitank filled with latex and CPO by 1% can lead to structural damage as it gives highest maximum value of total deformation for these capacities. Since the situation of the flexitank are in the braking condition, the highest elastic equivalent strain is occurred at the front-top of the flexitank structure.Downloads

Download data is not yet available.