Effect of Impeller’s Blade Number on The Performance of Mixing Flow in Stirred Tank using CFD Simulation Method

DOI:

https://doi.org/10.37934/cfdl.14.5.3342Keywords:

Stirred tank, Impeller, Number of blades, velocity magnitude, CFDAbstract

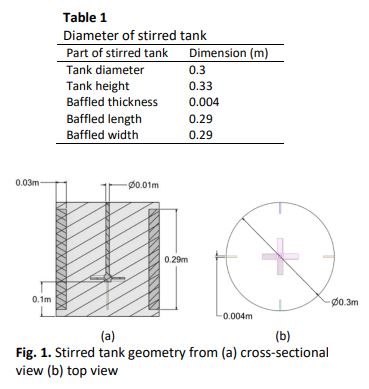

The component of an impeller in stirred tank plays an important role in the mixing process for a wide range of industries. The present study conducted the analysis of impeller design specifically on the number of blades to investigate the flow performance in the stirred tank. The analysis was also performed to identify the location of the particle flow dead zone at the bottom of the tank. The grid development and fluid flow study were accomplished using the CFD simulation method via the Ansys Fluent software package. The impeller design with the arrangement of 3,4 and 5 blades number was involved in this study. The rotational speed of the blade was set constant at 90 rpm. The flow characteristic at the vertical position of a tank at 0.01, 0.1, 0.2 and 0.3 m has been investigated. The general governing equation and solution approach used in this simulation were also presented in this paper. The results showed that 5 blades impeller produced a broader region of high-velocity magnitude distribution compared to the 3 and 4 blades. Hence, 5 blades impeller also relatively produced a higher distribution of velocity magnitude compared to the 3 and 4 blades impeller, typically in the upper region of the tank. However, the effect of a number of blades seemed not significant in the region close to the rotating impeller.

Downloads

References

Hoseini, S. S., G. Najafi, B. Ghobadian, and A. H. Akbarzadeh. "Impeller shape-optimization of stirred-tank reactor: CFD and fluid structure interaction analyses." Chemical Engineering Journal 413 (2021): 127497. https://doi.org/10.1016/j.cej.2020.127497

Shu, Lei, Mingjin Yang, Hang Zhao, Tianfu Li, Ling Yang, Xiang Zou, and Yunwu Li. "Process optimization in a stirred tank bioreactor based on CFD-Taguchi method: A case study." Journal of Cleaner Production 230 (2019): 1074-1084. https://doi.org/10.1016/j.jclepro.2019.05.083

Ameur, Houari, and Youcef Kamla. "Geometrical modifications of the anchor impeller to enhance the overall performances in stirred tanks." Instal 6 (2020): 42-45. https://doi.org/10.36119/15.2020.6.5

Rasool, Adnan AAR, Safaa S. Ahmad, and Faik Hamad. "Effect of impeller type and rotational speed on flow behavior in fully baffled mixing tank." International Journal of Advanced Research (IJAR) 5, no. 1 (2017): 1195-1208. https://doi.org/10.21474/IJAR01/2871

Jaszczur, Marek, Anna Młynarczykowska, and Luana Demurtas. "Effect of impeller design on power characteristics and Newtonian fluids mixing efficiency in a mechanically agitated vessel at low Reynolds numbers." Energies 13, no. 3 (2020): 640. https://doi.org/10.3390/en13030640

Agarwal, Alankar, Gurveer Singh, and Akshay Prakash. "Numerical investigation of flow behavior in double-rushton turbine stirred tank bioreactor." Materials today: proceedings 43 (2021): 51-57. https://doi.org/10.1016/j.matpr.2020.11.208

Ameur, Houari, Youcef Kamla, and Djamel Sahel. "Optimization of the operating and design conditions to reduce the power consumption in a vessel stirred by a paddle impeller." Periodica Polytechnica Mechanical Engineering 62, no. 4 (2018): 312-319. https://doi.org/10.3311/PPme.12372

Joanna Pyzel, “Change and Continuity in the Danubian Longhouses of Lowland Poland,” in Tracking the Neolithic House in Europe, eds. Hofmann D., Smyth J. (New York: Springer, 2013), 183-196. https://doi.org/10.1016/j.jtice.2020.11.013

Gu, Deyin, Mei Ye, Xingming Wang, and Zuohua Liu. "Numerical investigation on mixing characteristics of floating and sinking particles in a stirred tank with fractal impellers." Journal of the Taiwan Institute of Chemical Engineers 116 (2020): 51-61. https://doi.org/10.1016/j.apt.2019.06.028

Hu, Yinyu, Zhe Liu, Jichu Yang, Yong Jin, and Yi Cheng. "Study on the reactive mixing process in an unbaffled stirred tank using planar laser-induced fluorescence (PLIF) technique." Chemical engineering science 65, no. 15 (2010): 4511-4518. https://doi.org/10.1016/j.ces.2010.04.033

Mahrous, Abdel-Fattah. "Computational Fluid Dynamics Study of a Modified Savonius Rotor Blade by Universal Consideration of Blade Shape Factor Concept." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 85, no. 1 (2021): 22-39. https://doi.org/10.37934/arfmts.85.1.2239

Ahmad, Mohd Nazri, Mohammad Khalid Wahid, Nurul Ain Maidin, Mohd Hidayat Ab Rahman, Mohd Hairizal Osman, Ridhwan Jumaidin, and Muhammad Afiq Abu Hassan. "Flow Analysis of Five-Axis Impeller in Vacuum Casting by Computer Simulation." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 61, no. 2 (2019): 181-189.

Gradov, Dmitry, Arto Laari, and Tuomas Koiranen. "Assessment of Interaction between Baffles and Impeller Blades in Stirred Tanks." In MATEC Web of Conferences, vol. 49, p. 04002. EDP Sciences, 2016. https://doi.org/10.1051/matecconf/20164904002

Fluent, A. N. S. Y. S. "Ansys fluent theory guide." Ansys Inc., USA 15317 (2011): 724-746.

Torotwa, Ian, and Changying Ji. "A study of the mixing performance of different impeller designs in stirred vessels using computational fluid dynamics." Designs 2, no. 1 (2018): 10. https://doi.org/10.3390/designs2010010

Qing, Nelvin Kaw Chee, Nor Afzanizam Samiran, and Razlin Abd Rashid. "CFD Simulation analysis of Sub-Component in Municipal Solid Waste Gasification using Plasma Downdraft Technique." Journal of Advanced Research in Numerical Heat Transfer 8, no. 1 (2022): 36-43.

Subramaniam, Thineshwaran, and Mohammad Rasidi Rasani. "Pulsatile CFD Numerical Simulation to investigate the effect of various degree and position of stenosis on carotid artery hemodynamics." Journal of Advanced Research in Applied Sciences and Engineering Technology 26, no. 2 (2022): 29-40. https://doi.org/10.37934/araset.26.2.2940

Caillet, Hélène, Alain Bastide, and Laetitia Adelard. "CFD Simulations in Mechanically Stirred Tank and Flow Field Analysis: Application to the Wastewater (Sugarcane Vinasse) Anaerobic Digestion." Promising Techniques for Wastewater Treatment and Water Quality Assessment (2021): 179. https://doi.org/10.5772/intechopen.93926

Stuparu, Adrian, Romeo Susan-Resiga, and Constantin Tanasa. "CFD assessment of the hydrodynamic performance of two impellers for a baffled stirred reactor." Applied Sciences 11, no. 11 (2021): 4949. https://doi.org/10.3390/app11114949