Optimization of CNC Turning Parameters for cutting Al6061 to Achieve Good Surface Roughness Based on Taguchi Method

Keywords:

Optimization, CNC turning, Surface roughness, Taguchi methodAbstract

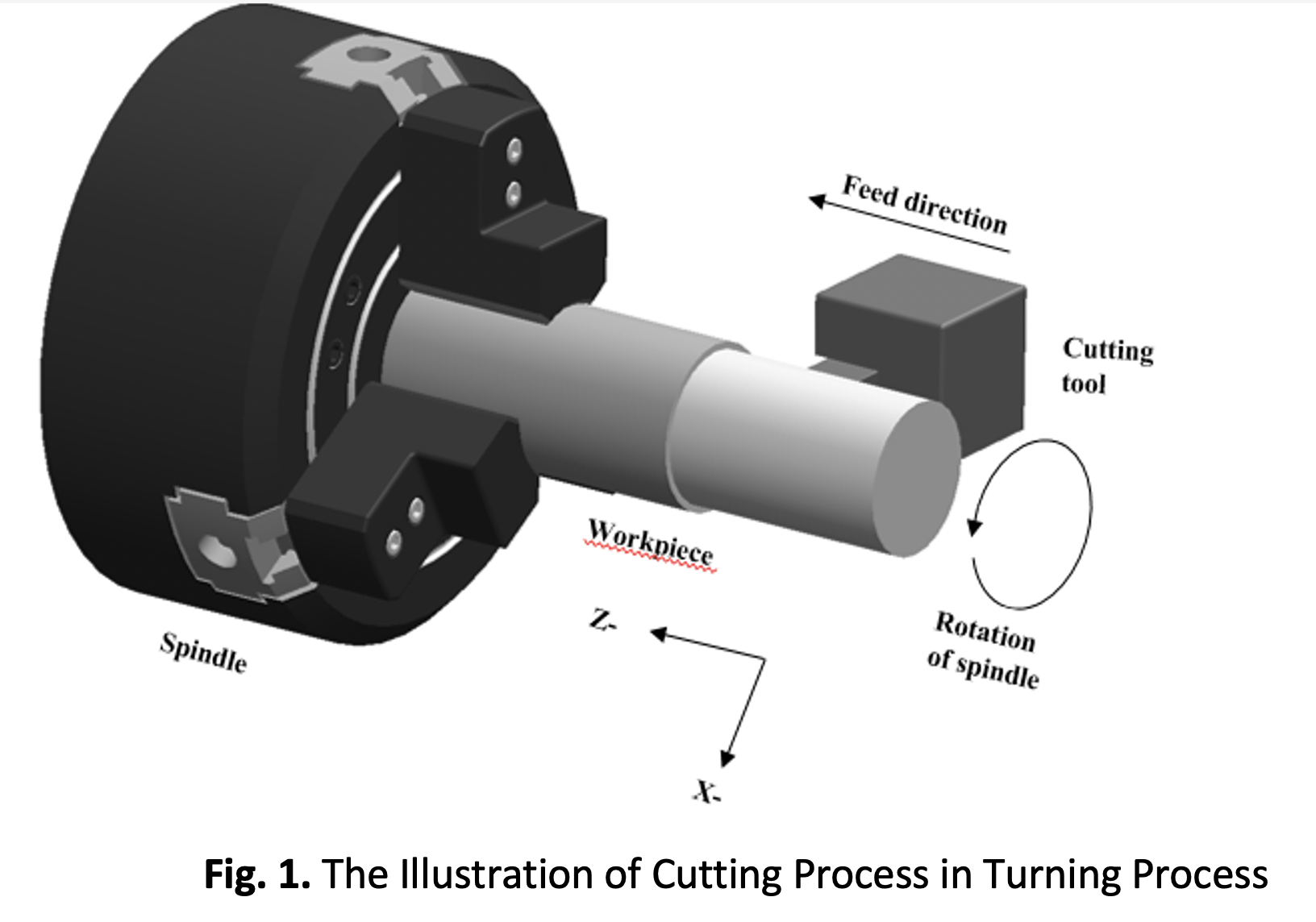

In the machining process of manufacturing sector, surface quality is critical factor in evaluating output of product. One of the machining processes is by CNC turning. The excellent surface finish ensures that the product is in the high quality. The industries are in the requirement of producing more parts with acceptable quality with the shortest period and the least resources. Some materials used for manufacturing parts have various kinds. This study applied Al6061 as workpiece and used Taguchi method to optimize the CNC turning parameter for cutting it. The Taguchi L9 orthogonal array experimental design was used in this research. In the CNC turning process, spindle speed, feed rate, and depth of cut were chosen as controllable process parameters, and surface roughness was utilized to assess performance as a response. The result will be analyzed by main effect plot, ANOVA, and the residual normal probability plot. In this research, 1000 rpm as a spindle speed, 0.08 mm/min as a feed rate, and 0.25 mm as a depth of cut were found to be the optimal parameters for achieving lower. The primary effect plot provides considerable data to support the experiment's principal goal. Furthermore, according to the ANOVA table, feed rate was the cutting parameter with the largest percent contribution to achieve better surface roughness, and the residual normal probability plot revealed that the coefficient model was significant.Downloads

Downloads

Published

2023-01-01

How to Cite

Hidayat, N. A. Mahbubah, M. Nuruddin, S. S. Dahda, D. Andesta, E. Ismiyah, … Y. P. Negoro. (2023). Optimization of CNC Turning Parameters for cutting Al6061 to Achieve Good Surface Roughness Based on Taguchi Method. Journal of Advanced Research in Applied Mechanics, 99(1), 1–9. Retrieved from https://semarakilmu.com.my/journals/index.php/appl_mech/article/view/1454

Issue

Section

Articles