Electrical Discharge Coating of Mild Steel with Fly Ash Suspension

DOI:

https://doi.org/10.37934/aram.112.1.19Keywords:

Fly ash, Electrical Discharge Coating (EDC), mild steel, surface modification, material migrationAbstract

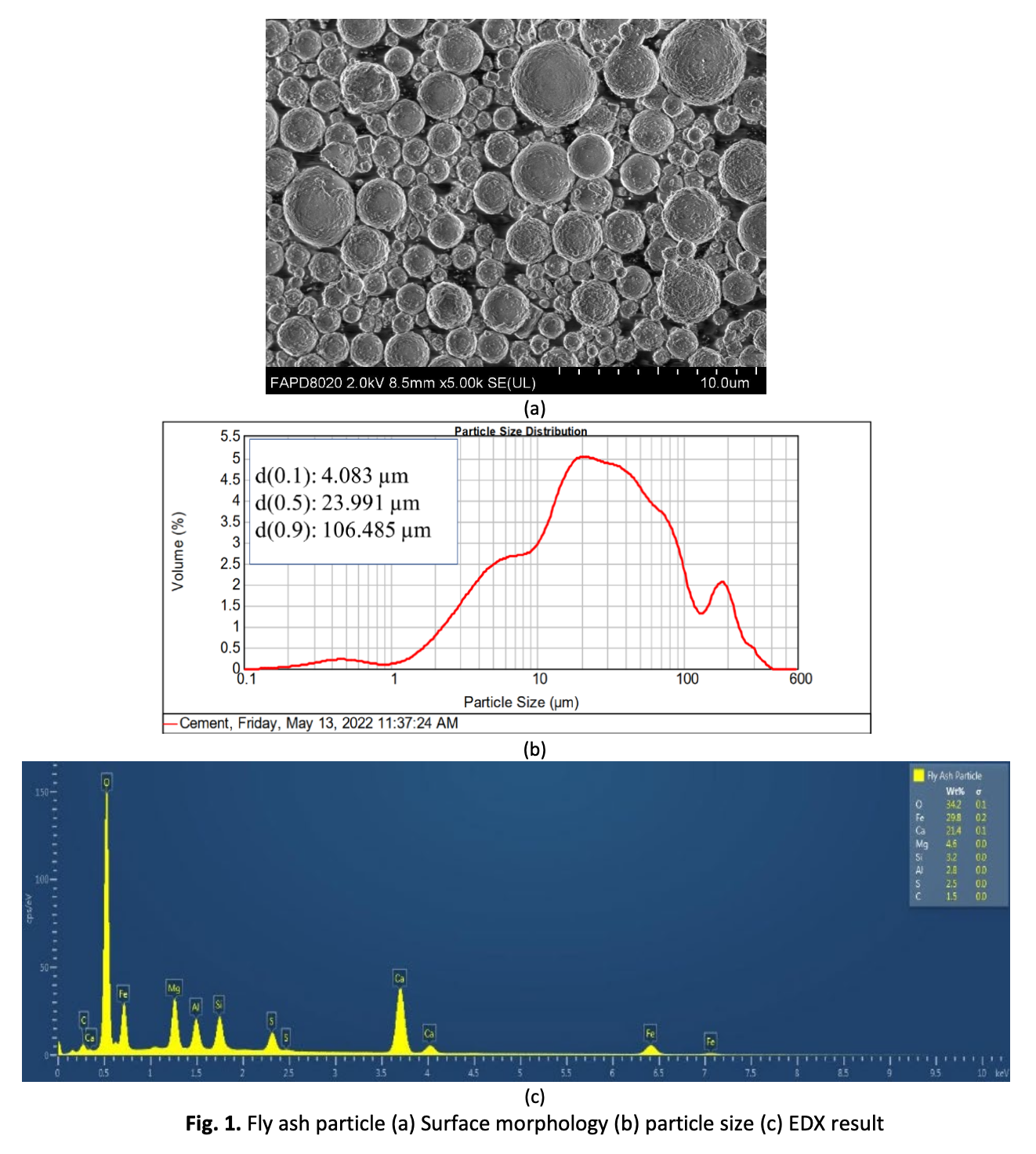

Mild steel is a soft substance that rusts easily. It is easy to wear and corrode when exposed to harsh circumstances, such as in manufacturing sector. As a result, the mild steel surface must be modified to boost its durability and wearability. There are various techniques for coating mild steel and one of them is electrical discharge coating (EDC). In this study, the surface of mild steel was modified using EDC with fly ash suspension. Prior to the experiment, the element content, particle size, and surface morphology of fly ash were investigated. The EDC process was carried out using a Sodick AQ35L die-sinker EDM machine. The effects of varied amounts of fly ash on the features of the coated surface were also investigated. The experimental results revealed that raising the fly ash content increases the micro-hardness of the coated surface. Furthermore, utilising 20 g/l of fly ash powder resulted in the best coated surface finish with the least surface roughness. The concentration of fly ash has a significant impact on the thickness of the coating layer. These findings substantiate the viability of recycling fly ash as an environmentally sustainable coating material for modifying mild steel surfaces through the EDC method.

Downloads