Characterization of Nanocellulose from Orange Peel Waste

DOI:

https://doi.org/10.37934/aram.112.1.1020Keywords:

Orange Peel Waste, Nanocellulose, Crystallite Index, Crystallite SizeAbstract

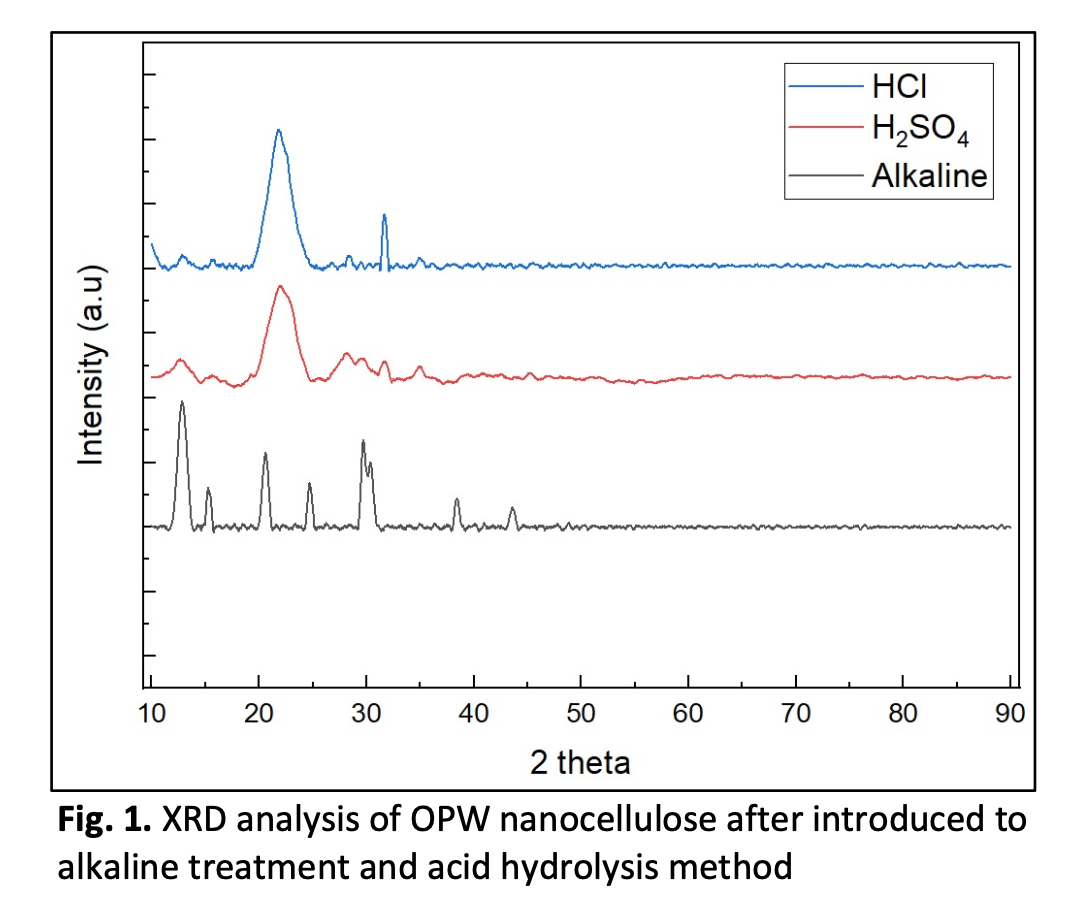

Orange peel is a commercially available natural fiber with an increasing interest in using it as a raw material in a variety of applications due to its high cellulose concentration in the plant. This research aims to determine the preparation of nanocellulose from orange peel waste (OPW) by using chemical treatment of acid hydrolysis method. In order to provide the optimum conditions of nanocellulose of OPW which are possessed high crystallinity in their crystal structure by using acid hydrolysis method and the effects of various acid concentrations on the crystallinity index, crystallite size and morphology of cellulose nanocrystals were studied. However, based on the previous study, using OPW there is limited study has been reported on type of acid and optimum acid concentration as a parameter of using hydrolysis method. Therefore, in this study, the process of preparation OPW nanocellulose by using acid hydrolysis method with the best type of acid used of sulphuric acid (H2SO4) and hydrochloric acid (HCl), optimum acid concentration (30-40 wt%), constant hydrolysis time (120 min) and constant temperature (45 °C) is comprehensively studied. Based on the achieved outcomes, the H2SO4 emerges as the most favorable approach for acid hydrolysis technique, effectively yielding finely dispersed crystalline cellulose while mitigating undesirable aggregation effects. The optimal acid concentration of 30 wt%, coupled with a 120 minute hydrolysis duration and a temperature of 45 °C, yields the most favorable results in terms of both crystallinity index and crystallite size, reaching remarkable values of 87.69 % and 3.19 nm, respectively. The nanocellulose derived from OPW holds significant potential as an environmentally sustainable material, aligning harmoniously with prevailing global trends in design and development for enhanced sustainability.

Downloads