Numerical and Experimental Investigation on Aluminium 6061 Solid Cylindrical Bar Subjected to Close-in Blast Loading

DOI:

https://doi.org/10.37934/aram.113.1.138151Keywords:

ABAQUS, Aluminum 6061, Deformation behaviour, Explosion impact, Explosive compactionAbstract

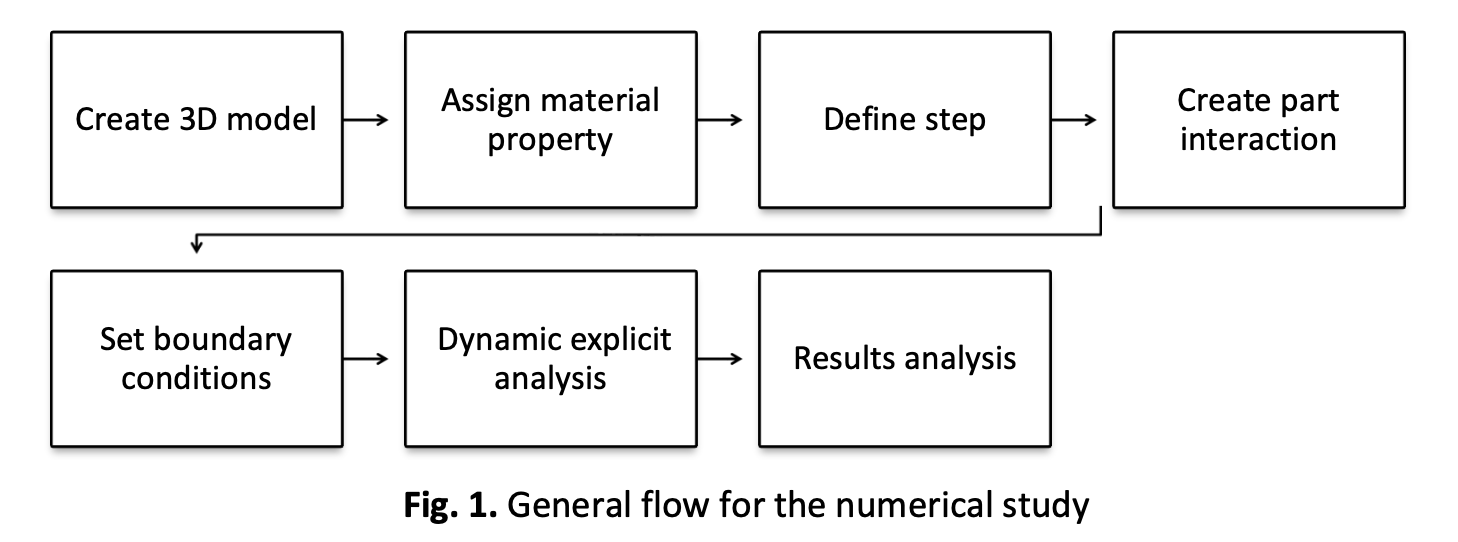

Compaction force generated by blasting load requires strong material such as steel to act as a plunger to spread the force evenly. The problem with this method is retaining the plunger's original dimension from intolerable deformation. This paper uses ABAQUS software to study the ability to predict the response of solid cylindrical aluminium bars (6061) subjected to different close-in blast loads. The solid cylindrical aluminium bars treated as a plunger were evaluated numerically using a combination of the finite element method (FEM) and smoothed particle hydrodynamic (SPH) methods. The plunger was simulated using the Johnson-Cook (J.C.) model, and Jones-Wilkins-Lee (JWL) equation parameters modelled the explosive. Field tests were conducted by detonating explosives of two different weights, which are 100g and 250g, in the designated blast area. Both data and observation were compared and analysed regarding deformation behaviour in term of dimension difference and fracture. Based on the graph of the deformation dimension versus the plunger length, the deformation trend shows a very close relation between numerical and experimental data with a percentage error of less than 4%. The fracture mode generated using FEM is comparable to the actual specimen. This fracture mode can be described as similar to the behaviour of the specimen obtained using the Taylor impact test. Thus, it can be concluded that the numerical analysis performed for this study is consistent with the actual results.

Downloads