Finite Element Analysis of the Main Structure for a New Conceptual Aircraft Passenger Vertical Seat Design

DOI:

https://doi.org/10.37934/aram.112.1.114124Keywords:

Standing seat, aircraft cabin, FEA, vertical seat, standing cabinAbstract

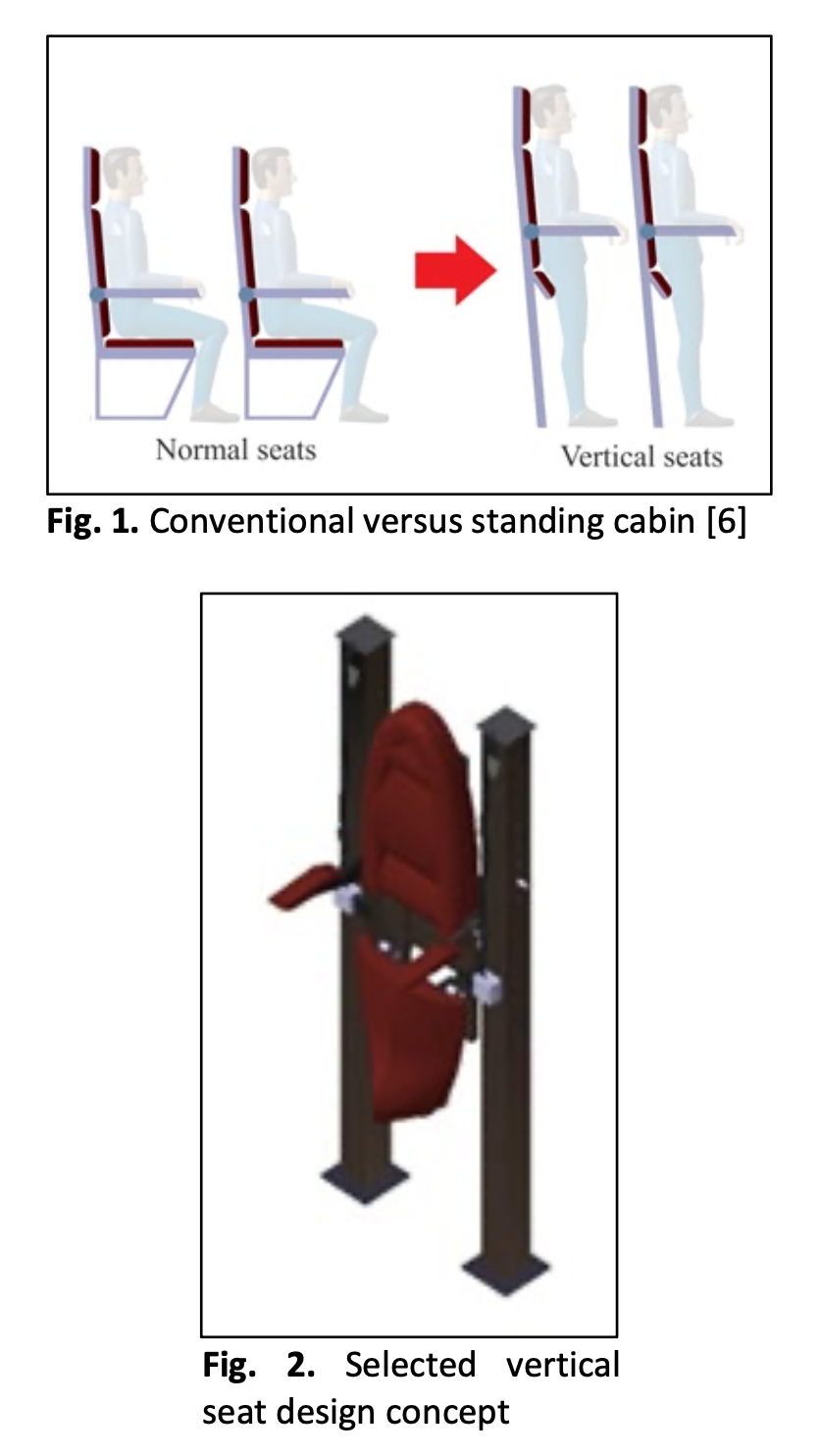

Standing cabin is a new design concept of aircraft passenger cabin whereby passengers are transported in the standing position throughout flight as opposed to current seated position. An important element of this cabin concept is the design of the vertical seat to support the passengers, which has to be in compliance with requirements of aviation regulation. In commercial aircraft applications, weight of passenger seat is a significant factor that can affect flight performance of the aircraft. Meanwhile, the seat’s structure should have adequate strength to ensure proper safety provision to passengers. Hence weight and strength are potentially two conflicting design requirements for the vertical seat, and the optimum structural design should have the best compromise with regards to these two requirements. In this study, parametric study on primary structural design of the proposed vertical seat concept is done to obtain an optimized design that satisfies the strength requirements for safety of passengers without causing high penalty to the overall aircraft weight and performance. The simulation analysis for the main structures of the vertical seat design is conducted through finite element method using ABAQUS software. From the results of the analysis, main structural parts made from aluminium alloy with diameter 90 mm and thickness 3 mm are selected for the optimum vertical seat design. This standing seat design has also been shown to have adequate strength and can satisfy the safety regulation requirement without failure. The maximum stress on the seat’s structure under 9-g forward loading is found to be 147.5 MPa, which is lower than ultimate strength of aluminium. Moreover, the seat’s weight is estimated to be 9.5 kg and the maximum deflection of its main structures under forward 9-g loading is 28.42 mm. All in all, the stress analysis results highlight that the structural strength of the optimal vertical seat design can satisfy the requirements of the governing aviation regulations to provide safety to passengers.

Downloads