Characteristics of Sand-Waste Tyre Rubber Composite as Backfill Material

DOI:

https://doi.org/10.37934/aram.115.1.6171Keywords:

Backfill, Waste Rubber Tyre, Sand-Rubber, Shear Stress, Direct ShearAbstract

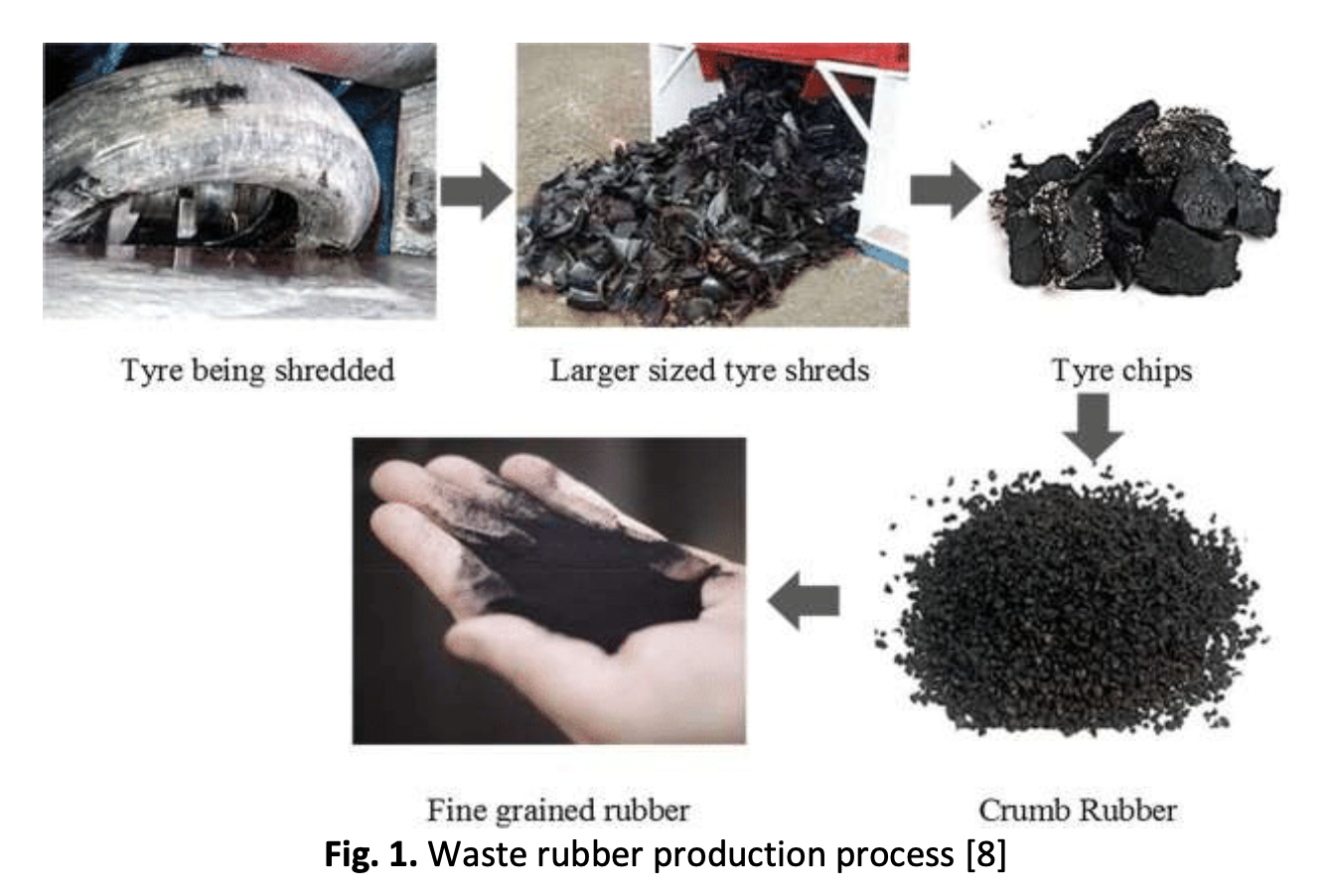

Waste tyre rubber offers an alternative to natural sand as a backfill material, potentially reducing the dependency on natural sand usage in construction. The purpose of this study is to investigate the properties of waste rubber as a potential backfill material for retaining walls and to assess the shear strength characteristics of the sand-rubber composite when used as a backfill for retaining walls, ultimately identifying the optimal sand-rubber composite ratio for effective backfill application. This study employed sieve analysis and specific gravity testing to identify the physical attributes of waste tyre rubber. Subsequently, direct shear box tests were conducted utilizing ratios of 100%, 50%, 75%, and 25%. Two types of rubber were utilized in this study Granulated Rubber (GR) with particle sizes ranging from 1 to 5 mm, and Mulch (MR) with particle sizes exceeding 25 mm. The findings reveal that the Cu value for waste rubber is less than 2.50 and the Gs value is less than 1.5, indicating favourable characteristics. Moreover, the 25% GR and MR compositions exhibit the highest shear stress values at 0.0347 N/m² and 0.0296 N/m², respectively. In conclusion, it has been determined that the optimal proportion of waste rubber for the application of the sand-waste tyre rubber composite as a backfill material is 25%.

Downloads