An Analysis of Urban Vehicle Body Aerodynamics Using Computational Fluid Dynamics for the Shell Eco-Marathon Challenge

DOI:

https://doi.org/10.37934/araset.30.2.7591Keywords:

Aerodynamics, urban vehicle, shell eco marathon, bodywork, computational fluid dynamics, fuel efficiencyAbstract

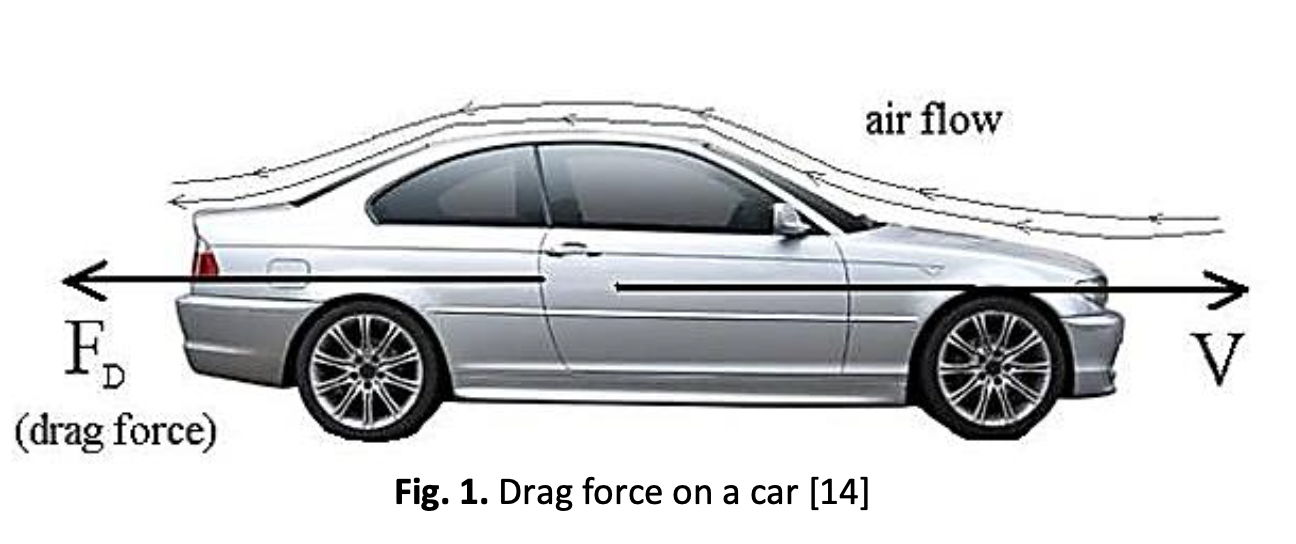

The Shell Eco-Marathon challenge is an annual competition held to challenge students in innovating the most fuel efficiency vehicle for either a prototype or an urban concept vehicle. An urban concept vehicle is designed for fuel efficiency using electricity as source of power. Apart from the use of electricity as an alternative to internal combustion engines, the design of the vehicle is also crucial for efficiency. The car bodywork design needs to be aerodynamically designed to minimise drag and subsequently use less energy to move. The design must also incorporate structural integrity to protect the driver as well as providing airflow for sufficient ventilation both inside the passenger and the engine compartment. Five models for the rear and front designs were produced using CATIA and analysed using Computational Fluid Dynamics in ANSYS Fluent. The models underwent a virtual wind tunnel on three different air velocity speeds, 20 km/h, 30 km/h and 40 km/h to generate a force report of drag force and coefficient on each design. The front design is chosen based on the lowest drag coefficient and force while the rear design is selected based on a balanced downforce while achieving the lowest practical drag force. The results demonstrated that the air resistance faced by a car was highly influenced by both front and rear design of the body.

Downloads