Durability Properties of Lightweight Foamed Concrete Reinforced With ‘Musa Acuminate’ Fibre

DOI:

https://doi.org/10.37934/araset.29.2.145158Keywords:

Foamed concrete, Musa acuminate fibre, Water absorption, Porosity, ShrinkageAbstract

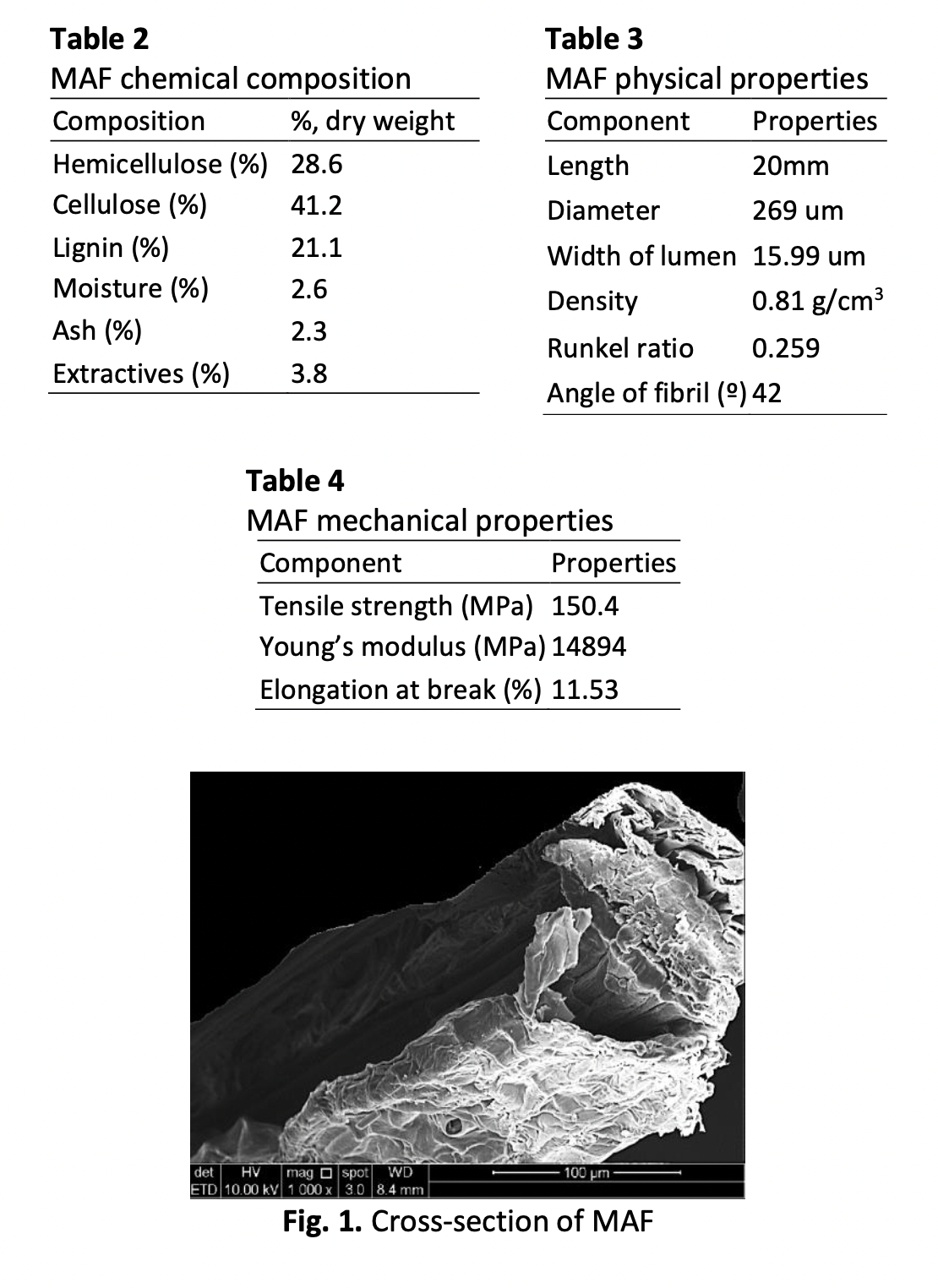

The demand for lightweight building materials that are easy to work with, self-compacting, and environmentally friendly has been acknowledged by the construction industry globally. Given this demand, it has been discovered that a recent innovative material, lightweight foamed concrete (LFC), may be able to reduce the weight of ordinary concrete. Besides, utilizing LFC with the addition of natural fibres is seen as a great effort to assist sustainability. Corrosion of reinforcing steel, which affects the behaviour and longevity of concrete buildings, is one of the most significant challenges in the construction of reinforced LFC. Therefore, the focus of this work is on identifying the possible application of Musa Acuminate fibre (MAF) in LFC. The intention of this study is to ascertain the durability characteristics of LFC with MAF. The cast has a low density of 550 kg/m3. We'll employ several volume fractions of MAF that are 0.15%, 0.30%, 0.45%, and 0.60%. The ability to absorb water, porosity, drying shrinkage and ultrasonic pulse velocity are the four criteria that will be evaluated. For the purpose of creating the necessary density of LFC, the protein-based foaming agent Noraite PA-1 was used. A constant water-to-cement ratio of 0.45 and a constant cement-to-sand ratio of 1.5 were used to get comparable results. The findings showed that for all of the durability attributes taken into account in this research, an increase of 0.45% MAF produced the best results. This resulted from the MAF and LFC cementitious composite's better bonding performance. Additionally, the fibres served as an anti-micro crack, preventing LFC cracks.

Downloads