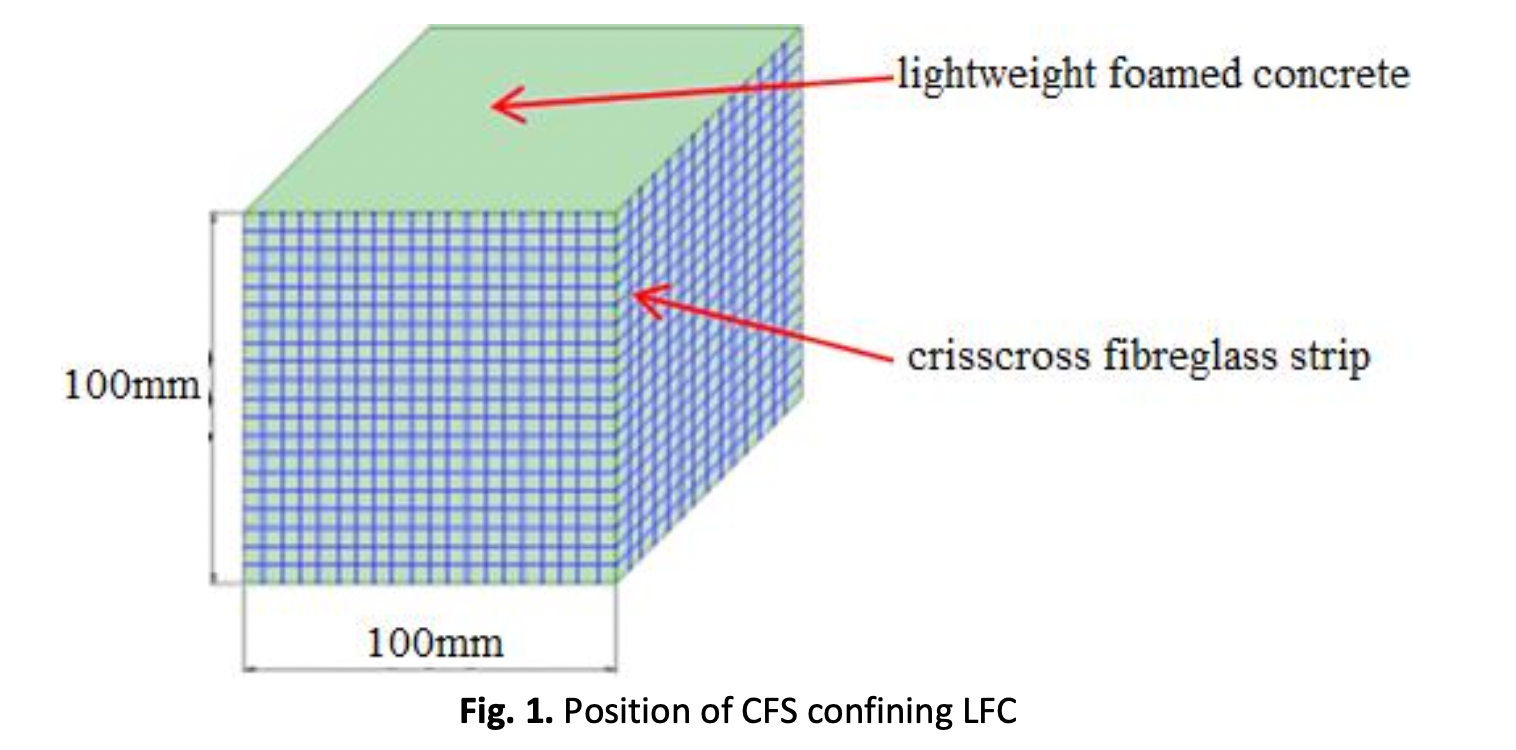

Influence of Crisscross Fiberglass Strip on Axial Compressive Strength of Lightweight Foamed Concrete

DOI:

https://doi.org/10.37934/araset.29.2.135144Keywords:

Foamed concrete, Compressive strength, Textile fabric, JacketingAbstract

Concrete use as a building component is already associated with the global construction sector. Since extensive research on concrete has been conducted for many years, there is a growing interest among researchers to conduct studies to increase the capacity of concrete for use in the building sector. Lightweight foamed concrete is one of the cutting-edge solutions developed for lighter and more sustainable buildings. Although this type of concrete has several benefits, its strength is still viewed as being inferior to that of regular concrete. By limiting the LFC with a crisscross fiberglass strip, the authors of this work will demonstrate improvements in LFC behaviour in terms of its compressive strength (CFS). To examine its improvements, 3 different LFC densities were cast and contained with 1 to 3 layers of 160 g/m2 CFS. For this test, the cement-to-sand ratio was fixed at 1.1:5, and the water content was set at 0.45. The results revealed that the compressive strength of LFC confined with 1 to 3 layers of CFS increased by 153%, 97% and 102% were acquired for 600, 1100 and 1600 kg/m3 densities respectively. This demonstrates that the number of layers used affects how positively the confinement of CFS affects the compressive behaviour of LFC.

Downloads