Computational Study on Thermal Management of IC Chips with Phase Change Materials

DOI:

https://doi.org/10.37934/arnht.26.1.3443Keywords:

CFD, IC chips, Phase change material, Thermal controlAbstract

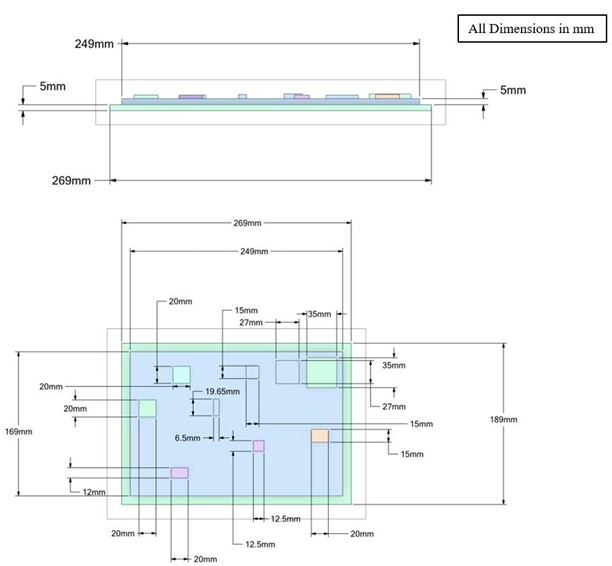

This paper presents an implicit transient numerical formulation for a novel passive thermal management system using minichannels to cool heterogeneous IC chips on a substrate board. The proposed design incorporates phase change materials (PCM) within minichannels situated around the periphery of the IC chips. By direct conduction from the substrate board, the PCM absorbs latent heat, facilitating its phase transition from solid to liquid, thereby enhancing the thermal cooling performance of the system. The study compares the thermal performance of three configurations: a system without PCM, a system with minichannel-coupled PCM, and an optimized single minichannel positioned near the heat source. The effectiveness of different PCMs, namely paraffin wax, N-Eicosane, and ATP 78, is also evaluated. Results indicate that N-Eicosane outperforms the other PCMs in providing effective cooling. Specifically, the implementation of N-Eicosane PCM results in a system temperature reduction from 53.234°C in the generic model to 51.520°C. This constitutes a significant temperature drop of 1.74°C compared to the generic model, with an additional reduction of 0.5°C and 1.35°C when compared to paraffin wax and ATP 78 PCM, respectively.

Downloads