Steam Methane Reforming in a Swirling Flow: Effect of Reformer Design Parameters

DOI:

https://doi.org/10.37934/arfmts.104.1.93105Keywords:

Steam methane reforming, hydrogen, reformer designAbstract

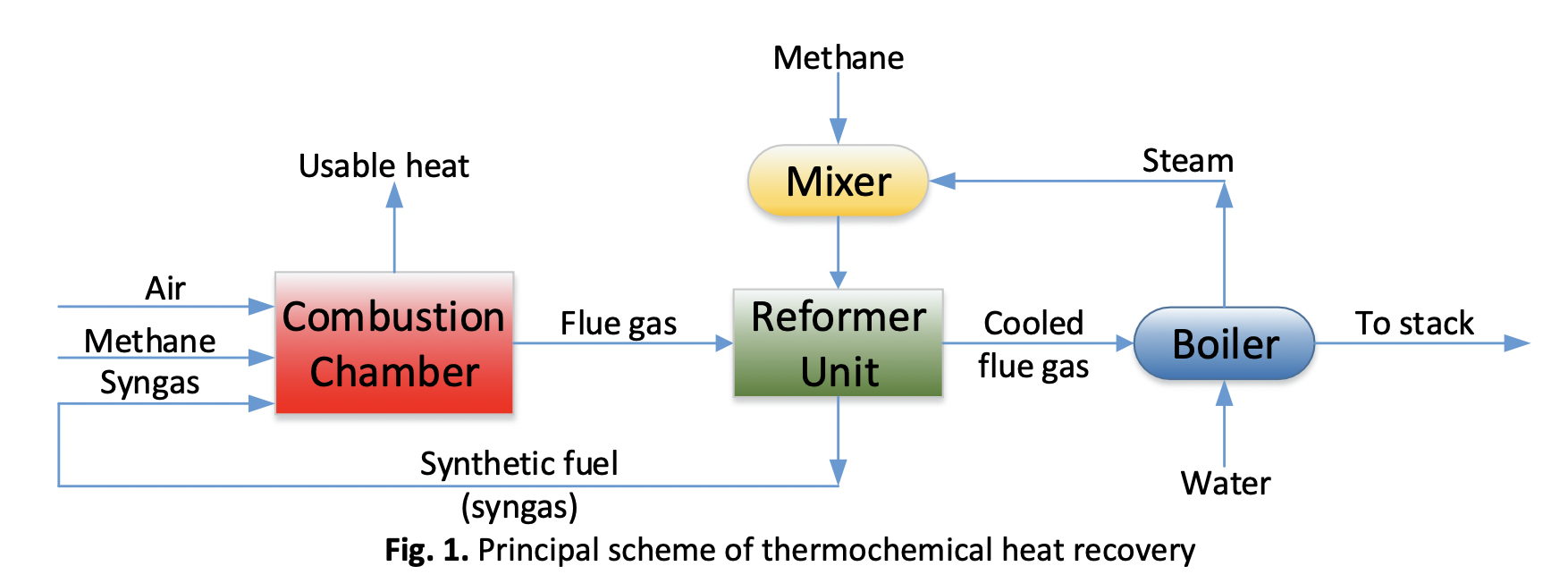

Climate change is mostly driven by extensive fossil fuel combustion. Therefore, the transition to clean energy sources and energy efficiency technologies are of great importance. Thermochemical regeneration (TCR) is a method of combined energy efficiency improvement and clean fuel production. Reactor design has a significant impact on the process efficiency and therefore is a key parameter. In the present study, three different reactor geometries were considered: cylinder, square-shaped tube and complicated cylinder. Ansys Fluent was used to model the steam methane reforming reactions in porous media. The influence of the reactor shape on the operating conditions (pressure, velocity, temperature, CH4 conversion) was assessed. Complicated cylindrical shape produced the highest amount of H2 but had the highest pressure drop. Square-shaped tube performed better from the production of H2 per unit of pressure drop perspective. Moreover, the effect of swirled flow on the process performance was studied. In summary, the effective reformer design was chosen and swirl flow suggestions were proposed.

Downloads