Effect of the Catalyst Shapes and the Packed Bed Structure on the Efficiency of Steam Methane Reforming

DOI:

https://doi.org/10.37934/arfmts.104.1.124140Keywords:

Steam methane reforming, hydrogen, reformer designAbstract

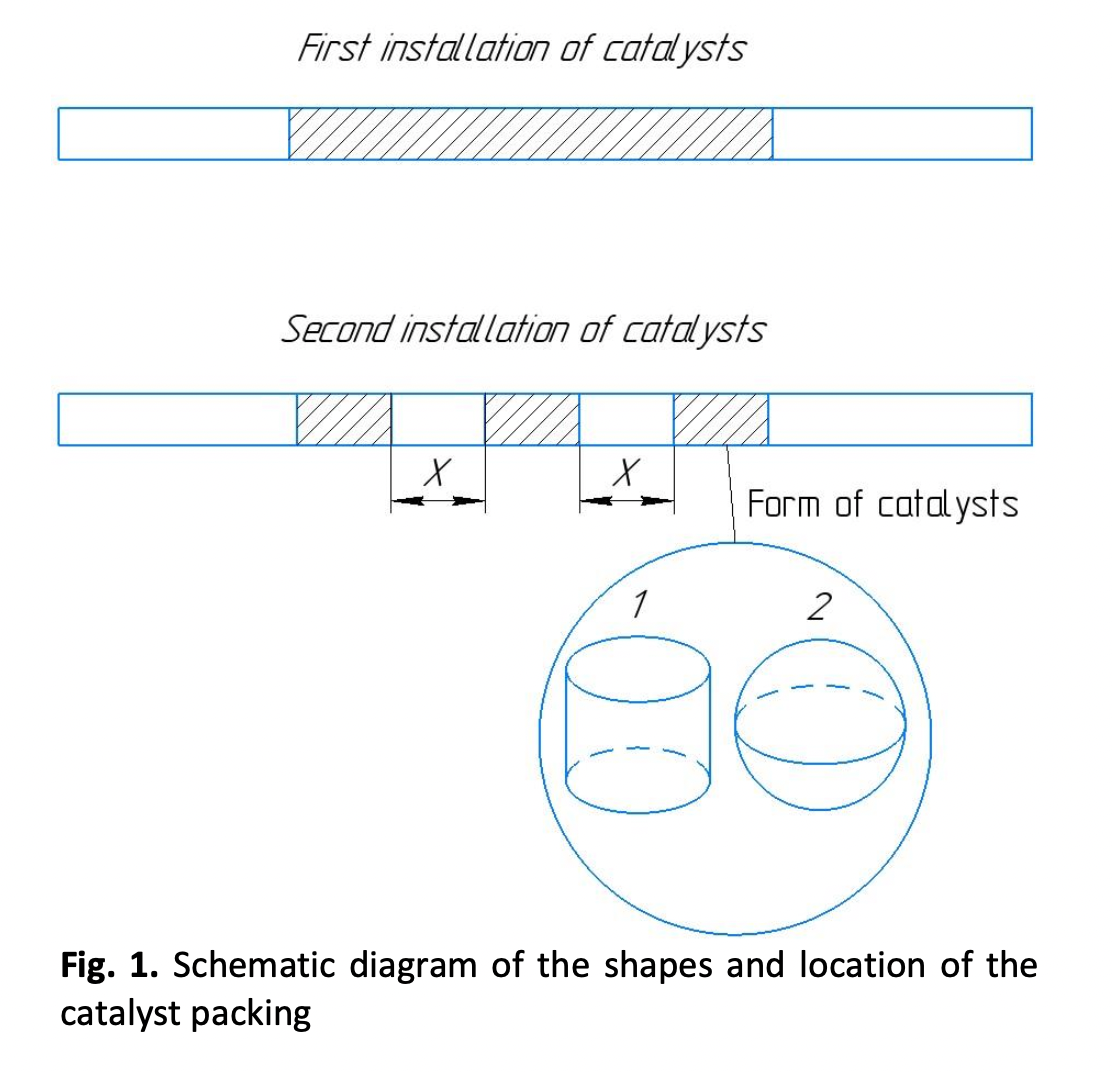

One of the promising technologies for on-board hydrogen production is methane steam reforming in reactor with packed bed. The study of the effect of various catalytic packing arrangements on the steam methane reforming process is of considerable interest. The present article analyses the influence of catalyst shapes and packing arrangement on steam methane reforming reactions efficiency. The reformer tube contains several packings with a changing relative position; additionally, two forms of catalysts, a ball and a cylinder, are also used. The pressure drop depending on the packing location, methane conversion and hydrogen yield were analysed. It was found that the packing arrangement with spacing allows better distribution of the supplied heat. Due to the distance between the packing sections flow becomes more turbulent after each section, which intensifies the heat transfer and mixing of the mixture. The highest hydrogen yield is observed on catalytic packings located at a distance of 40 mm from each other and consisting of cylindrical catalysts. The most uniform pressure drop occurs at a packing arrangement without spacing. The increase in methane conversion observed with the increment in spacing distance, but the difference is insignificant. Therefore, the arrangement of catalysts with spacing can be used for the improvement of steam methane reforming process.

Downloads