Drying Behavior of Moringa Oleifera Leaves using Tray Dryer

DOI:

https://doi.org/10.37934/arfmts.105.2.182191Keywords:

Moringa oleifera, drying, tray dryer, color, protein, iron, total phenolic content analysisAbstract

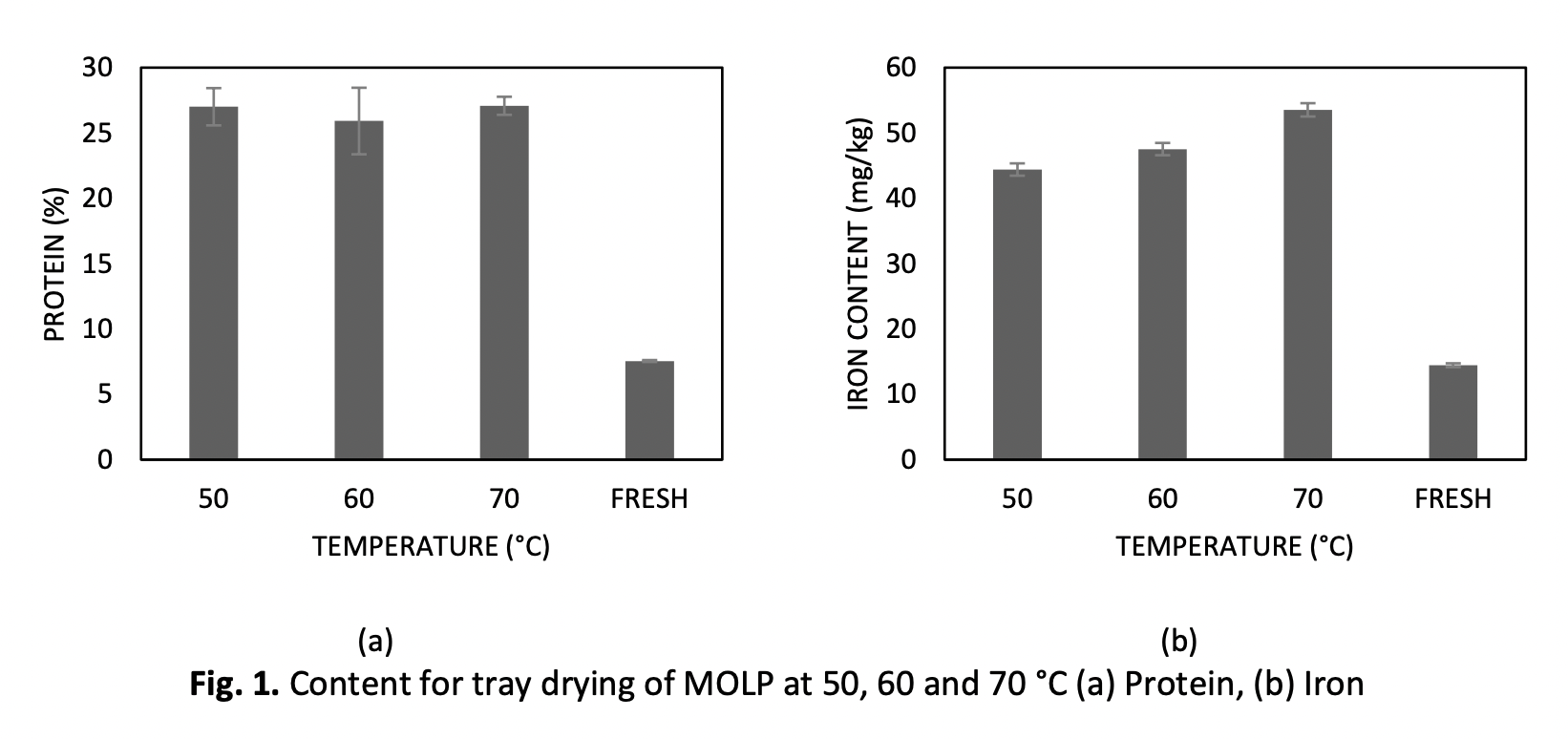

Moringa oleifera leaves have been dried in a tray drier to investigate the drying behaviors of Moringa oleifera leaves at three different temperatures for their moisture content, color, iron and protein content, as well as total phenolic content. Three levels of temperatures were chosen varying from 50, 60 and 70 °C in this study. Drying time reduced significantly with the rise in temperature. The final moisture content of dried leaves at 50, 60 and 70 °C was 4.89, 4.79, and 4.59 % and reached equilibrium moisture content at 4, 2, and 1.5 hours. For the water activity, all the dried leaves give a low amount of water activity from 0.0912 to 0.1838 at 70 - 50 °C where the higher the temperature the lower the water activity. This indicates that the lower the temperature, the slower the drying time required to decrease moisture content to below 5 % and a smaller amount of water activity. This ability to preserve its taste and nourishment. For the color changes, the value for greenness (-a) has no significant difference but notable differences were detected between the color parameters of fresh and dried leaves for whiteness L value and yellowness b. This shows that drying under a tray dryer has the same color as the fresh M. oleifera leaves. There was no notable difference in the value for protein but a significant difference (P<0.05) in the value for iron contents of the fresh and dried leaves. The total phenolic content (TPC) obtained from this study was 46.97 - 55.78 mg GAE/g FW for drying at 50 to 70 °C. Results from this study discover a great option for large-scale drying using method.

Downloads