Comparison of Thermal Effectiveness and Crevice Corrosion Risk of Fin Geometry on All-Aluminum Microchannel Heat Exchangers

DOI:

https://doi.org/10.37934/arfmts.105.2.192203Keywords:

Computational Fluid Dynamic (CFD), Microchannel heat exchanger (MCHE), crevice corrosion, pitting corrosion, corrosion hotspotAbstract

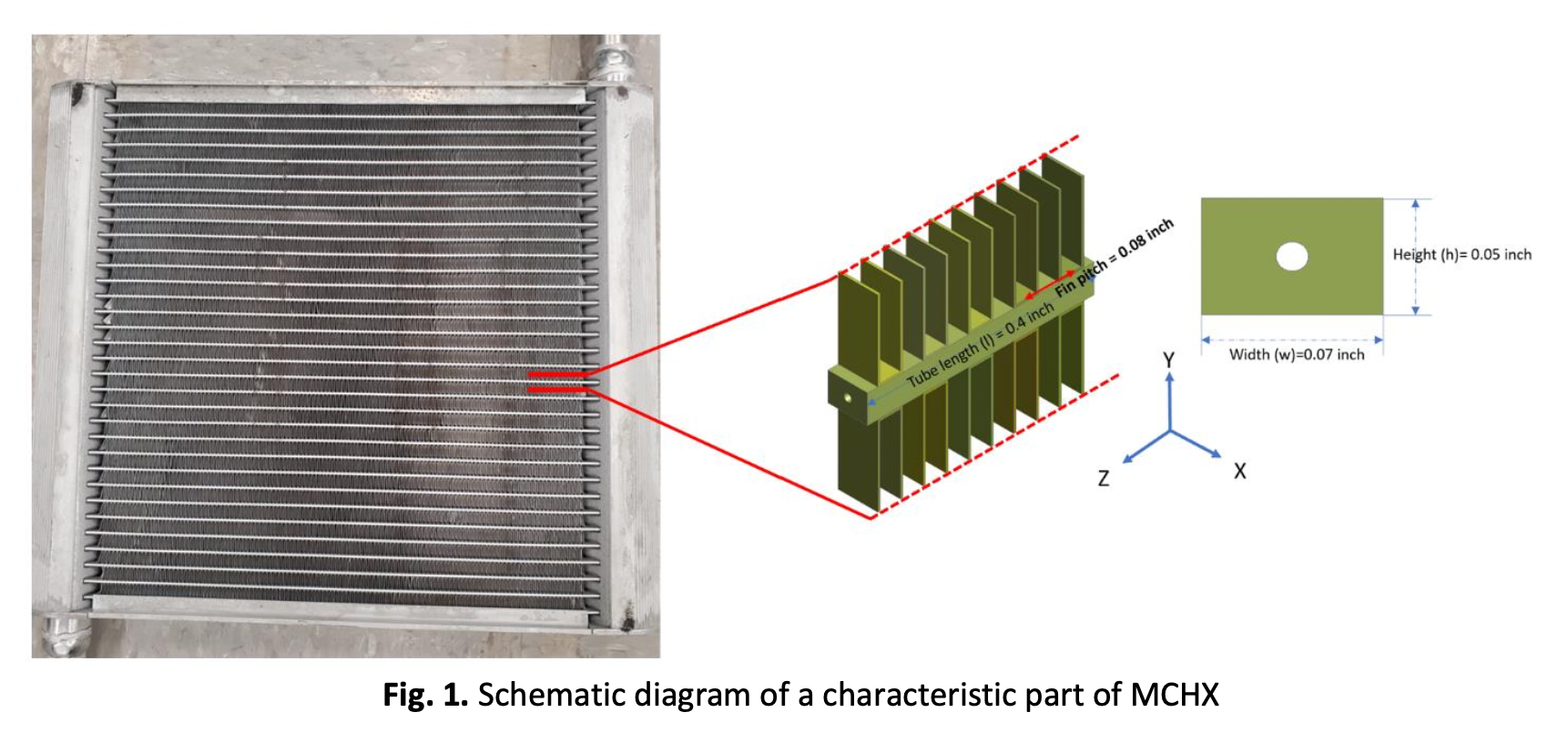

All-aluminum microchannel heat exchangers have recently gained popularity in the heating, ventilation, and air conditioning industry. Despite their attractive thermal performance design, these heat exchangers make coils used in automotive, commercial, and residential applications prone to crevice corrosion. This study uses high-fidelity conjugate heat transfer simulations to model a micro channel heat exchanger system that includes fins and tubes with crossflow to compare their thermal effectiveness to gain insight into potential crevice corrosion of the MCHE alloy. This study considers three fin geometries (louver, step, and saw) with the same tube and circular shape microchannel and identifies the corrosion hot spot and thermal effectiveness. A predicted flow field also identifies crevices between fins and tube surfaces as critical corrosion hot spots often associated with low-velocity regions. The crevice volumes for the louver, step, and saw fin shapes are calculated as respectively. Results also show that the same circular microchannel louver shape fin has higher effectiveness than the step and saw shape fin. The thermal effectiveness for microchannel tubes with louver, step, and saw shape fins are 0.337, 0.20737, and 0.2895, respectively.

Downloads