A Review on Cooling Methods of Lithium-Ion Battery Pack for Electric Vehicles Applications

DOI:

https://doi.org/10.37934/arfmts.115.2.113140Keywords:

Battery thermal management system, lithium-ion-battery, electric vehicles, phase change materialsAbstract

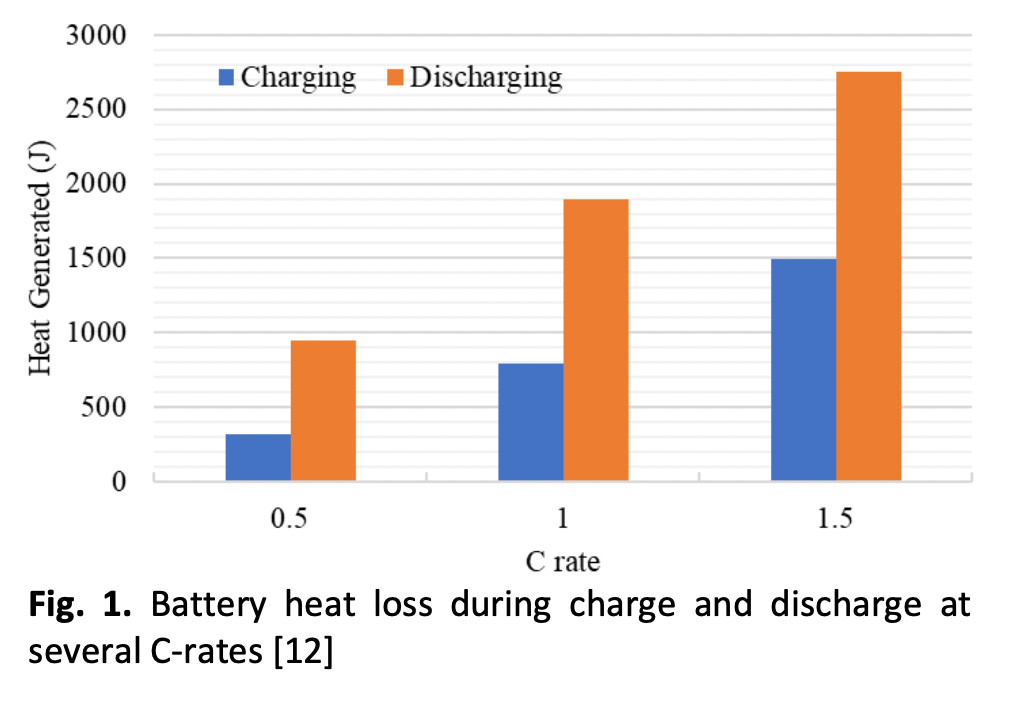

The thermal concerns, such as capacity loss, uneven temperature distribution and thermal runaway of the battery packs made of lithium-ion batteries (LIB) used in electric vehicles (EV), limits its applicability, especially in situations of high-power demand. This article analyses the causes of heat generation in lithium-ion battery packs, focusing on their dominance over total heat generation. It discusses the thermal issues arising from heat generation, their root causes, and influencing parameters. Further, it examines the effect of cooling systems on peak battery temperature and temperature uniformity, as well as their design, operating, and performance parameters. The review suggests that, when designing a cooling system, entropic heating should be considered alongside Joule heating during low discharge rates and high temperatures, which are the conditions that prevail when an EV cruises on highways in hot weather. Capacity fade of battery is caused by temperature-dependent factors such as the growth of the SEI layer, rise in separator resistance, and active material loss. Hence an effective battery cooling system should maintain a temperature range of 15°C to 35°C and ‘ΔTmax’ below 6°C. Out of the reviewed cooling systems, air cooling is found to be simple and cost effective, but inefficient for large battery packs. PCM based cooling technique offers greater temperature uniformity but is sensitive to melting point. Liquid cooling is most efficient but adds cost and complexity. Evaporative cooling can serve as a middle ground between air and liquid cooling with further research to put it into practice. The future research in battery thermal management may focus lowering the energy consumption of the cooling systems by taking into account, the precise cooling needs as per the modes of battery operation.

Downloads