A Review of the Effects of Plate Configurations and Electrolyte Strength on Production of Brown Gas Using Dry Cell Oxyhydrogen Generator

DOI:

https://doi.org/10.37934/arfmts.99.1.18Keywords:

Electrolysis, brown gas, oxyhydrogen generator, HHO gasAbstract

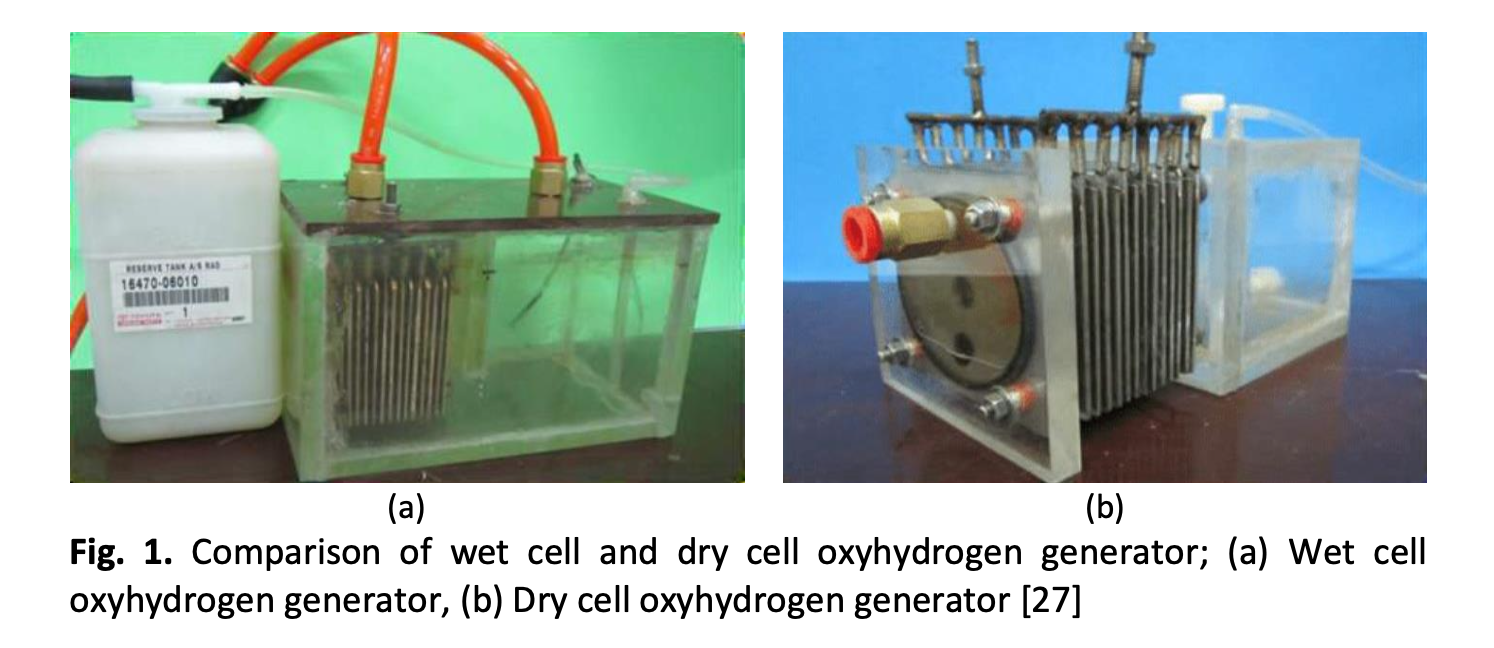

The production of brown gas (HHO gas) performance depends on the attribute of the oxyhydrogen generator. However, it is found that the main issue in the production of brown gas is the complexity of the oxyhydrogen generator system, electrolysis efficiency and safety. Therefore, this paper presents a review of the factors that affect the production of brown including the types of electrode materials, plate configurations, types of electrolytes, and the concentration of electrolytes. Furthermore, this study is also conducted to find out what are the suitable condition for each parameter stated in the research when using a dry cell oxyhydrogen generator in the production of brown gas. Therefore, it is found that by increasing the number of neutral plates and electrodes, the production of brown gas increases. Besides, the ideal plate orientation is the vertical position, and the suitable gap distance between each plate is 2 to 3 mm. Furthermore, the larger the cross-sectional area of plate, the higher the production of the brown gas. Not to mention, the ideal electrolyte that boosts the production of the brown gas is potassium hydroxide (KOH). In addition, dry cell oxyhydrogen generators are more preferred in the production of brown gas as it is much safer and offers more benefits than wet cell oxyhydrogen generators. This further demonstrates that the attribute of the oxyhydrogen generator does influence the production of brown gas.

Downloads