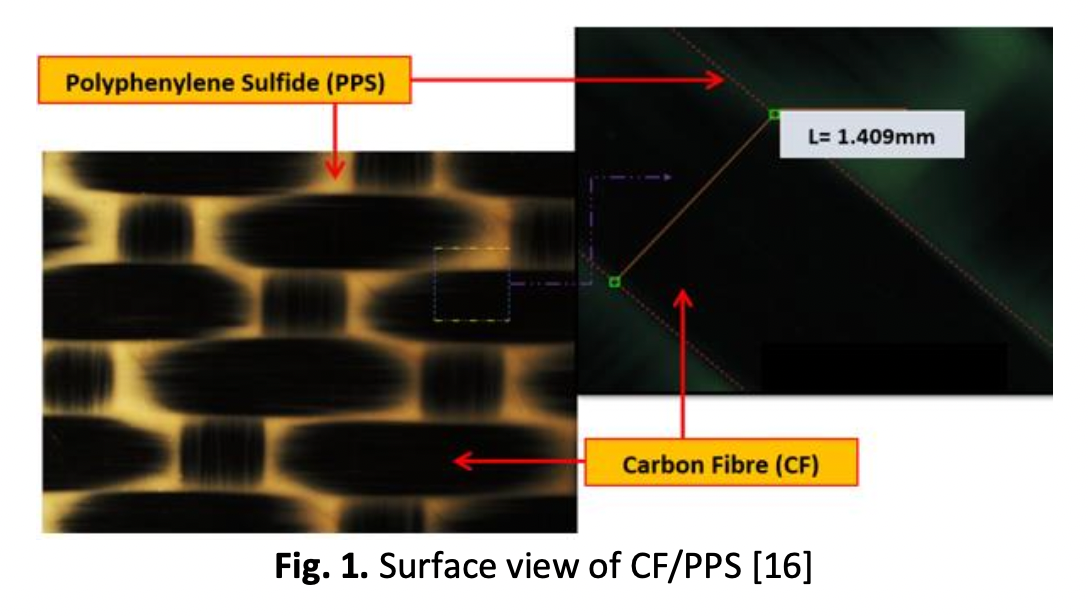

Characterization of Carbon Fibre Reinforced Polyphenylene Sulfide Composite under Interlaminar Shear Strength

DOI:

https://doi.org/10.37934/aram.102.1.19Keywords:

Thermoplastics, carbon fibre, Polyphenylene sulfide, interlaminar shear strengthAbstract

Aerospace industry is seeking thermoplastic composites materials due to several advantages over thermoset material and one of them is mechanical properties. Mechanical properties of thermoplastic composite materials are found to be superior compared to thermoset materials. High strength fibre composites parts are made of several plies with different fibre orientation with a designed balanced of lay-up sequence. Interlaminar Shear Strength (ILSS) is an essential consideration when designing laminated structures exposed to transverse stresses. It is to predict quality and strength of laminate levels of composite due to, composite failure cannot be observed directly to the propagation of single macroscopic crack when subjected to cyclic loading. This test is employed to evaluate both the interfacial adhesion of the matrix and the influence of the reinforcement on the mechanical characteristics of the composite. This study provides the understanding of ILSS test of 2 different thickness for 6 and 8 plies Carbon Fibre Reinforced Polyphenylene Sulfide (CF/PPS) according to the testing standard EN 2563. The results show that 8 plies have higher ILSS properties compared to 6 plies. The fractography of the CF/PPS composite under Scanning Electron Microscope (SEM) shows good agreement with the experimental values which was recorded 8 plies can withstand to shear strength of 79 MPa with maximum load applied was 2.738kN while, 6 plies recorded 75 MPa on shear strength with load of 1.971kN. More damage/cracks on 6 plies specimen compared to 8 plies.

Downloads