Cure Behaviour and Tensile Properties of Pineapple Leaf Fibre Reinforced Natural Rubber Composites

DOI:

https://doi.org/10.37934/aram.115.1.8897Keywords:

Tensile properties, natural rubber, pineapple leaf fibre, cure characteristics, scanning electron microscopyAbstract

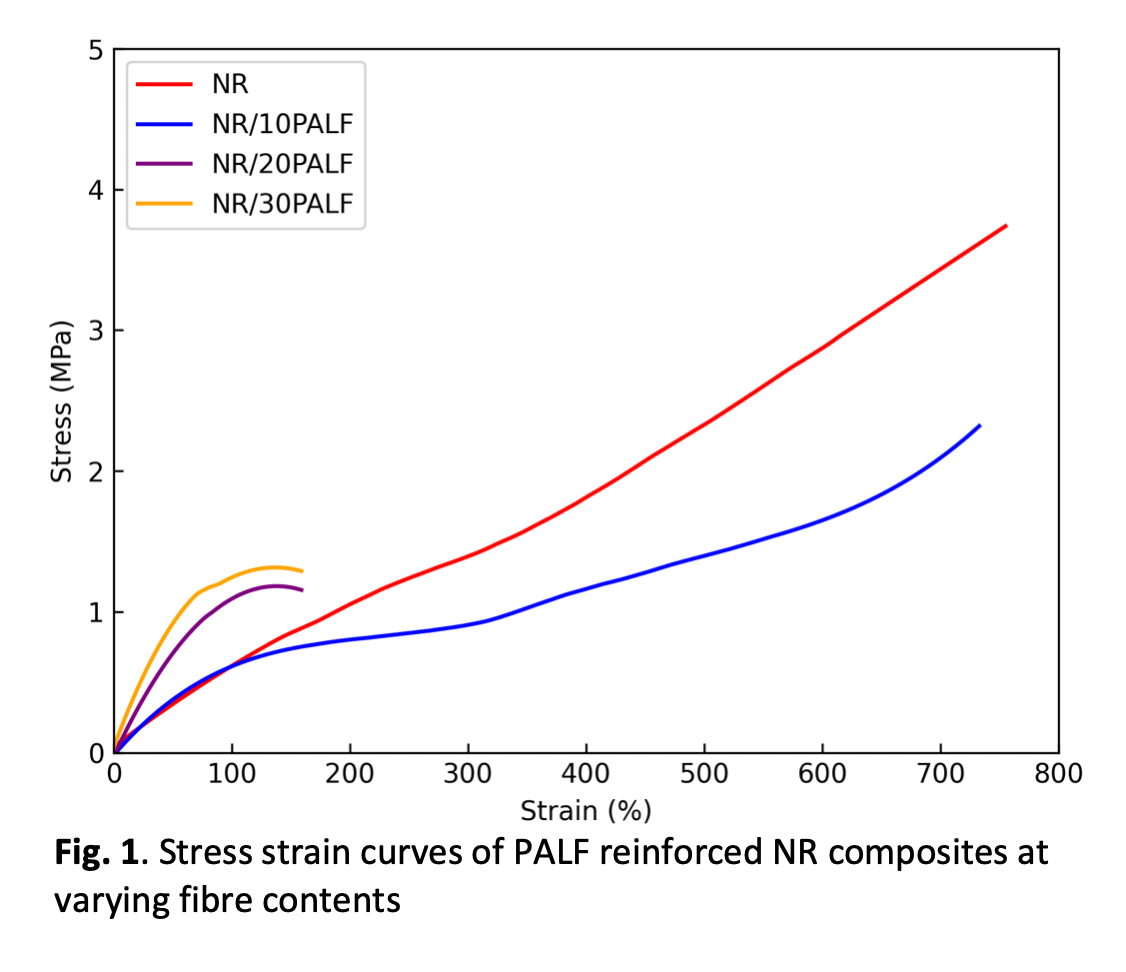

Short natural fibres replace synthetic fibres as filler in natural rubber (NR) as they are environmentally beneficial and sustainable. This study investigates the cure behaviour and tensile properties of pineapple leaf fibre (PALF) reinforced NR composites at various fibre contents. The fibre contents are varied at 0, 10, 20 and 30 parts per hundred rubber (phr). PALF reinforced NR composites are prepared using a two-roll mill. Surface morphology of tensile fractured specimens is examined using scanning electron microscopy (SEM). The results demonstrated that the optimum cure time decreases significantly with greater fibre content. The hardness value increases gradually with increasing filler content. The stress-strain graphs show an increasing trend in stress at higher fibre content particularly at low strain regions. On the contrary, the tensile strength reduces when the fibre content is increased up to 30 phr. SEM analysis reveals that the fibre-matrix adhesion is considerably poor due to the fibre pullout phenomenon observed. It is indicated that higher fibre content could be possibly reinforced to NR to achieve high deformation stress at incredibly low strain regions.

Downloads