Experimental Study on the Relation between the Energy Efficiency and Pressure Drop of Dual Inlet Cyclone Separator in Processing Indoor Farming Biomass Waste

DOI:

https://doi.org/10.37934/aram.104.1.4658Keywords:

Cyclone separator, pressure drop, energy efficiency, dual inlet cyclone, particle sizeAbstract

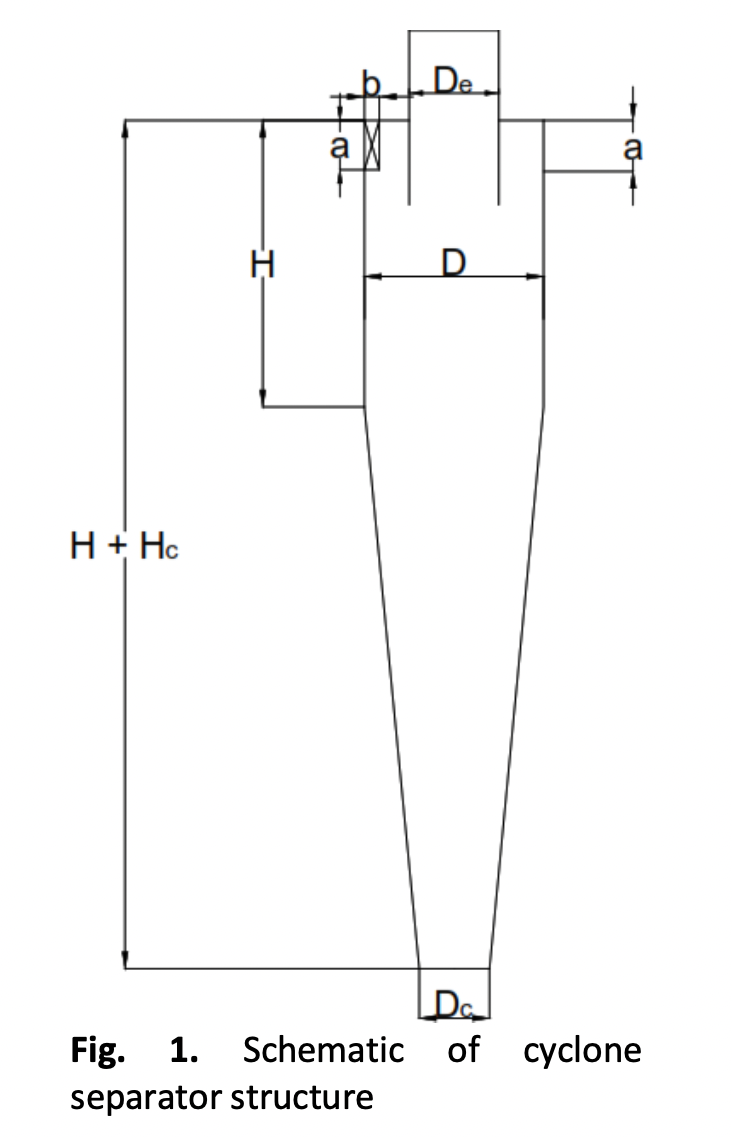

The cyclone separator is a device commonly used to separate particles from air, gas, or liquid streams. The addition of a secondary inlet is aimed at enhancing separation efficiency and productivity. This study aimed to investigate the relationship between energy efficiency and pressure drop in dual inlet cyclone separators. The cyclone separator was intended to be used in processing biomass waste from indoor farming. The experiment was conducted by varying the input velocity of the system and injecting sand particles into the cyclone separator. The results showed that energy efficiency is positively correlated with average particle size and negatively correlated with pressure drop and velocity. The highest energy efficiency was observed when using particles with a size of 624µm and an input velocity of 9 m/s. These findings suggest that optimizing particle size can lead to reduced energy usage and operational costs while minimizing environmental pollution. The present study provides a comprehensive understanding of the relationship between energy usage and efficiency in a cyclone separator, which can help industries improve their performance.

Downloads