Development of Smart Mini Manufacturing System Model for Industry 4.0 Application

DOI:

https://doi.org/10.37934/aram.114.1.94108Keywords:

Mini-smart manufacturing system, industry 4.0, physical model, remote model, wireless data collection and control, google apps script, internet of thingsAbstract

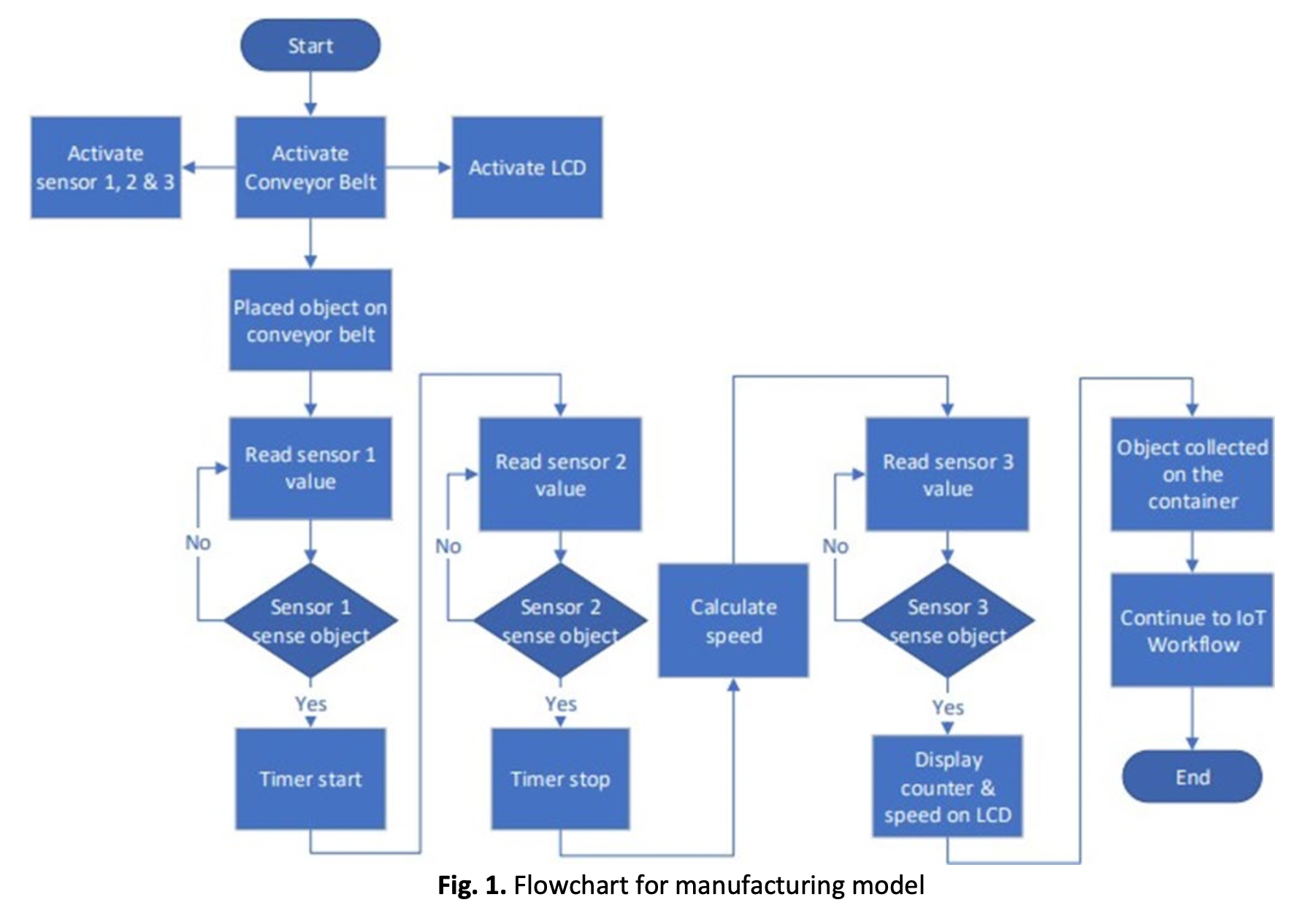

The theoretical mini-smart manufacturing system makes use of connected sensors, machines, and gadgets across the production line for real-time data collection. In several facets of the manufacturing process, such as quality control, predictive maintenance, inventory management, and supply chain optimization, it enables proactive decision-making and continuous improvement. The mini-smart manufacturing system's conceptual design transitions from a conventional to a smart manufacturing system using Industry 4.0. To illustrate the notion, the physical model and remote model are created. The NodeMCU ESP32 and sensors utilized in the physical model of a conveyor belt allow for wireless data collecting and control. The dashboard is created using Google Spreadsheets for real-time monitoring, data analysis, and control. It permits automatic data-driven decision-making based on a performance analysis algorithm that evaluates the actual result with the intended outcome. These two versions are linked together using the Google Apps Script so they may communicate wirelessly. Case studies are used to test the interoperability of physical, remote, and data-analysis methods to make sure it satisfies the requirements. Automation processes, such as data gathering, analysis, and control, demonstrate the viability and core components of the smart manufacturing system. Overall, the idea of a smart manufacturing system signifies a radical change in how industrial processes are conducted. It offers increased efficiency, productivity, and flexibility by utilizing cutting-edge technologies and data-driven decision-making. The proposed smart manufacturing system offers a plan for a manufacturing ecosystem that is prepared for the future as the manufacturing sector enters the era of Industry 4.0.

Downloads