Potential Red Algae Fibre Waste as a Raw Material for Biocomposite

DOI:

https://doi.org/10.37934/araset.30.1.303310Keywords:

Red algae, polylactic acid, biocomposite, extruderAbstract

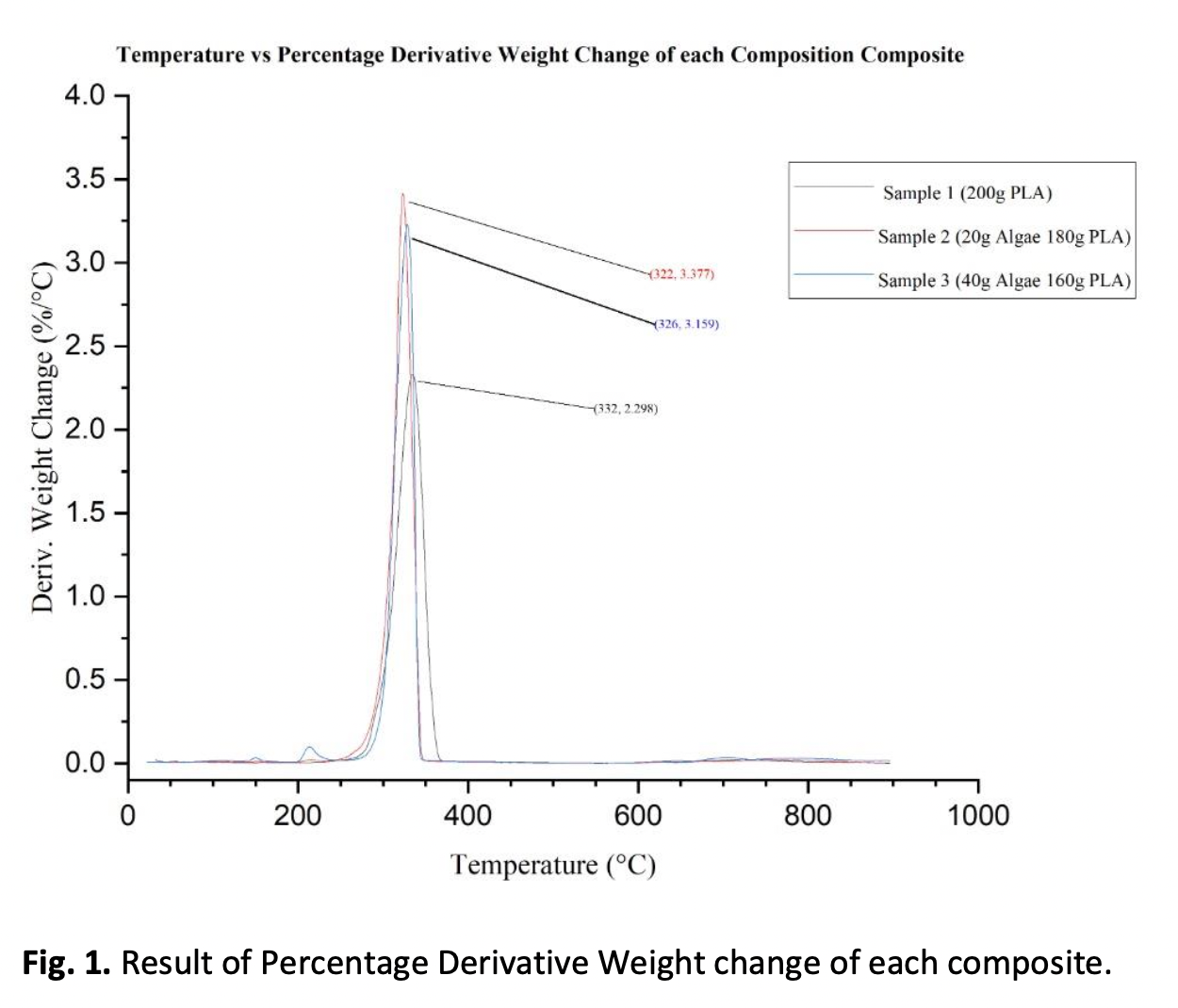

Red algae are abundant worldwide, and their exploitation for the development of agar products has developed into a significant industry in recent years. Industrial processing of red algae produces a significant amount of solid fibre waste, which contributes to substantial environmental problems. Agar from red algae is mostly used in the food, cosmetic, and pharmaceutical industries. There has been very limited research on the use of red algae in lignocellulosic composites so far. As such, this project aims to fabricate red algae reinforced with polylactic acid (PLA) as composite materials and to investigate the composite's mechanical, physical, and durability properties, as well as its characterization. The composite is fabricated using an extruder and a hydraulic hot press machine in three different composition ratios: 200:0, 180:20, and 160:40 (PLA: fibre (g)). Each sample was subjected to tensile testing for mechanical properties, melt flow index (MFI), scanning electron microscopy (SEM) testing for physical properties, and thermogravimetric analysis (TGA) testing for thermal properties. For durability testing, the samples were buried underground to determine the weight loss of composites over two weeks. The results indicate that while red algae have exceptional thermal properties, however, the strength and durability of the composite decrease with the inclusion of fibre. It is recommended that fibres be treated with an alkaline solution to improve their characteristics before being used as a composite.

Downloads