Analytical Hierarchy Process and Failure Mode and Effect Analysis on HVAC Semi-Hermetic Compressor Maintenance Strategy

DOI:

https://doi.org/10.37934/araset.32.3.256272Keywords:

Failure Mode, FMEA, Semi Hermetic Compressor, Risk Priority Number, AHPAbstract

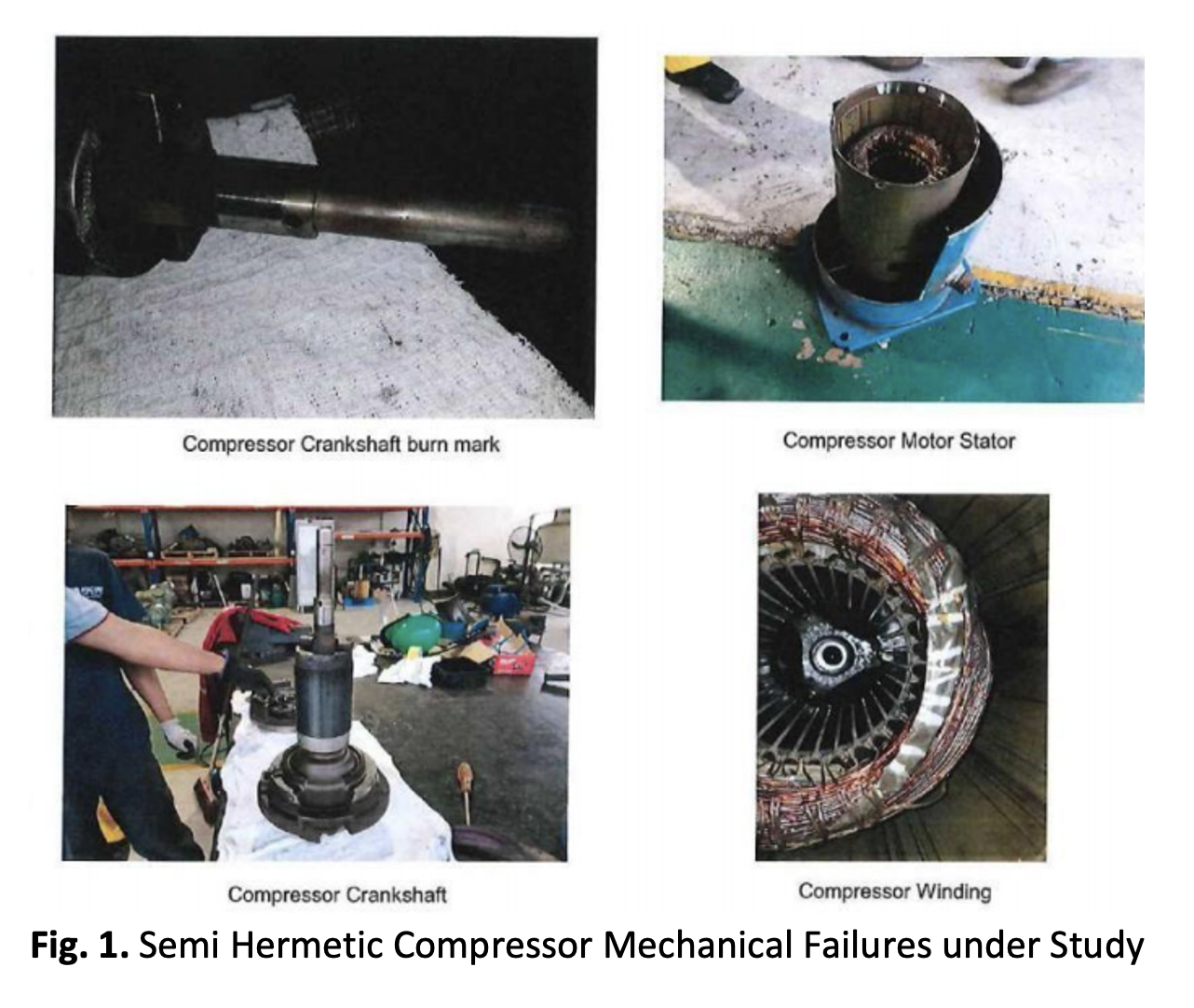

The article paper presents a strategic tool used in maintenance strategy deployment using failure mode and effect analysis method in oil and gas semi hermetic compressor perspective. This research aims to study and formulate framework of maintenance strategy using Analytical Hierarchical Process and Failure Mode and Effect Analysis of HVAC semi hermetic compressor used at the offshore oil platform. The case study has been conducted systematically at a company involved in maintenance activities at regular basis servicing HVAC equipment and parts which in this case focusing on Semi Hermetic Compressors at case studies taken from two companies, both involved in oil and gas production. The ranking of severity associated with Risk Priority Number in Failure Mode Effect Analysis table for this case study is obtained from assessment on maintenance history report lodged on Semi Hermetic Compressor serviced by the company. The severity assessment also studied based on Pareto Analysis on occurrence from maintenance history report. Based on the Failure Mode and Effect Analysis (FMEA) analysis, recommendations are made for semi hermetic compressor for maintenance strategy propositions to improve lifetime and reliability as FMEA output being used as input for synthesize using multi criteria method Analytical Hierarchical Process.

Downloads