Monitoring the Manufacturing Operation Process Data through the Cloud Database

DOI:

https://doi.org/10.37934/araset.50.1.276285Keywords:

Cloud, manufacturing operation, industrial applications, transaction controlAbstract

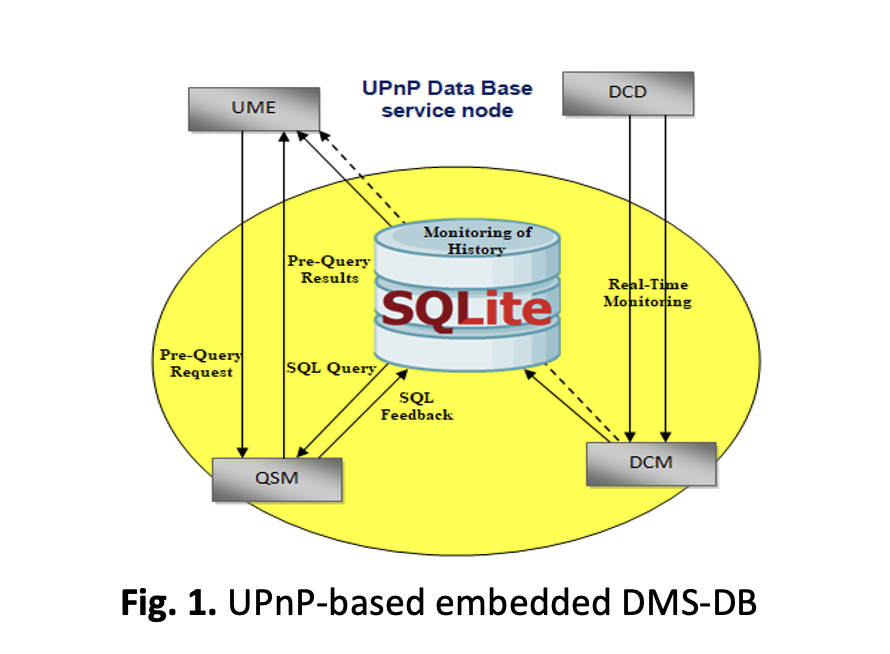

The level of service provided by disseminating industrial management was difficult to match by the customer or multivalent based on embedded data stores now in usage. An Embedded Cloud Database Service (ECDT) approach is proposed as a solution to the problems. To enhance the actual-time performance and dependability to transaction processing, ECDT architecture should be first built, and a Dual-Timing Transaction Control (DTC) mechanism was proposed. Then, a different network sniff-timing calculation method was presented to increase the effectiveness of the ECDT method, and a cloud services middleware component was built to carry out dynamic access control and real-time DB search. In comparison to MySQL and Berkeley DB, the total transaction processing time could be slashed by 45.5% and 36.7%, correspondingly. The DNS2 algorithm could also function with average demand and time change and use less energy. Finally, the results of the numerical and commercial experiments show that the DTC technique could improve the real period precision of transmission operations in a condition where reading consistency was guaranteed, and the data transfer speed could be 20 MB/s.

Downloads