Emission Characteristics and Engine Performance from Castor Oil Methyl Ester Blends in Diesel Engine under Various Injection Pressures

DOI:

https://doi.org/10.37934/arfmts.94.1.4559Keywords:

Castor oil, engine performance, fuel injection pressure, NOX emissions, CO2 emissions, PMAbstract

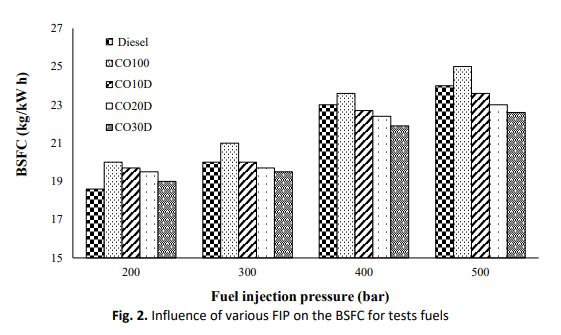

The use of fuel injection pressure and oxygenated fuels in transport sector are the considerable challenges in making environmentally clean without any modifications in engine design. Therefore, the influence of injection pressure on engine performance and exhaust emission characteristics of common-rail diesel engine has been investigated in this study. The research engine was operated with castor oil blended into the diesel in different percentages at different injection pressures (200, 300, 400 and 500 bar). The results showed that the BSFC increased by 37.2%, 26.8%, 24.53% and 20.31%, from the combustion of COD100, COD10, COD20 and COD30, respectively, and also the thermal efficiency increased from the oxygenated fuels in comparison with diesel under low and high injection pressure. Furthermore, the average reduction of CO and HC emissions was 27.4% and 21.6% from the combustion of castor oil-diesel (COD) blends under 500 bar. The NOX emissions slightly decreased by 7.3% with increasing the injection pressure up to 500 bar from all COD blends compared to the diesel. It is indicated that the CO2 emissions increased by 8.6% form the COD blends combustion compared to the diesel with increasing FIP. The PM concentrations gradually decreased with increase the injection pressures by 33.6%, 26.25%, 20.7%, and 17.4% from CO100, CO30D, CO20D and CO10D, respectively.

Downloads