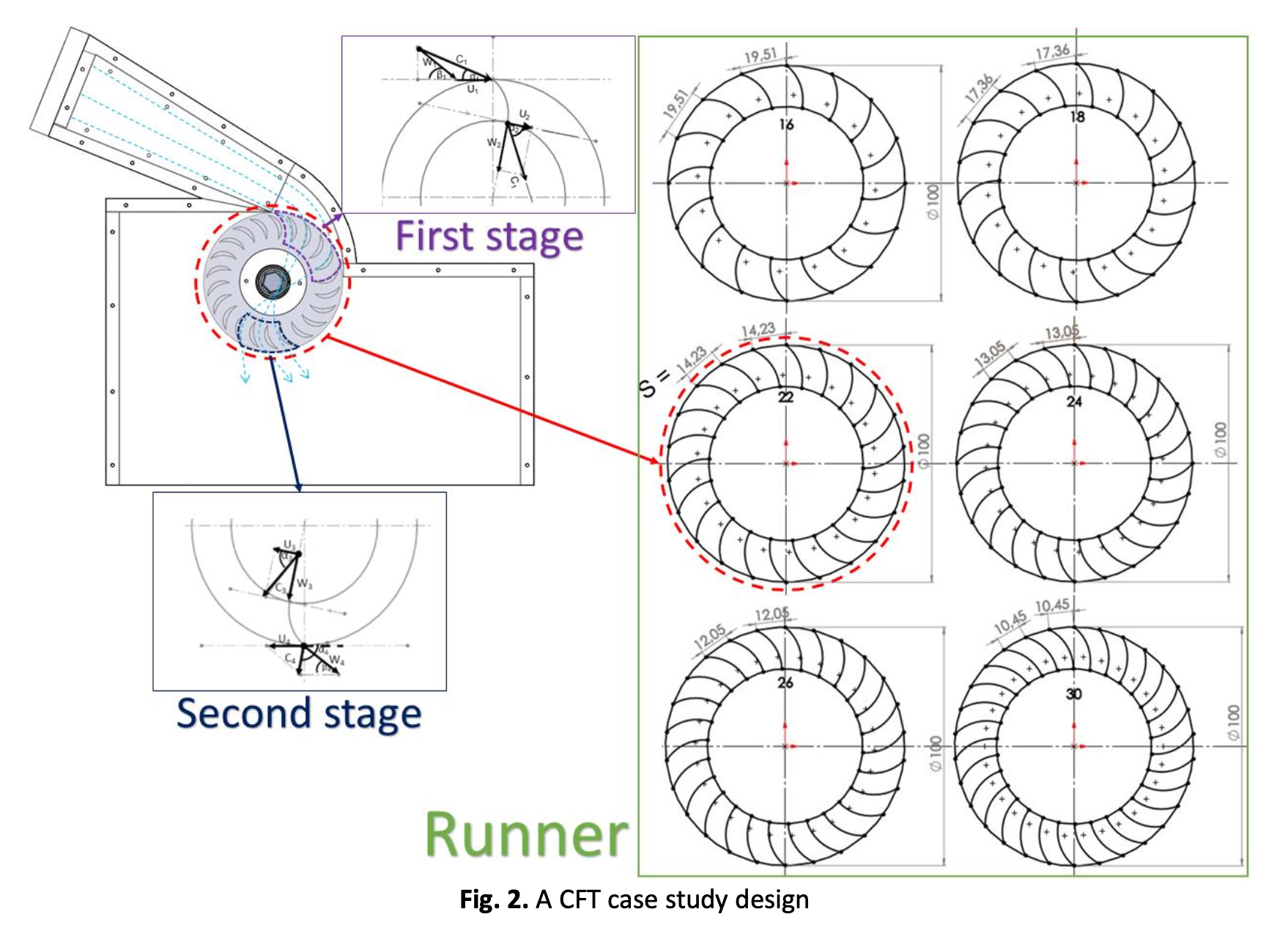

Investigation on the Blade Number of Pico-scale Crossflow Turbine for Low Head by Numerical Method

DOI:

https://doi.org/10.37934/arfmts.118.2.112Keywords:

Crossflow turbine, pico hydro, computational fluid dynamic, energy conversion, low headAbstract

Pico-scale crossflow turbines (CFT) can be an alternative solution to meet electrical energy needs, especially in remote rural areas. CFT is recommended because of its suitability in low head (< 5 m) conditions and fluctuating discharge conditions. One of the parameters that influences the performance of a CFT is the number of blades of the runner. CFT was discovered in 1903 and is still developing; however, the study of the physical phenomena of flow due to the blade number on the energy conversion process has yet to be comprehensively depicted. Therefore, this study aims to analyze the effect of the blade's number of runners on CFT performance using the computational fluid dynamics (CFD) method. The CFD method can visualize the flow field more detail than analytical and experimental. The CFD method is run with a moving mesh feature (transient) and pressure-based solver with a head condition of 3 m. The blades number studied were 16, 18, 22, 24, 26, and 30. Based on the results, the relationship of the CFT efficiency to blade number is described using a second-order multiple regression polynomial, and runner rotation is parabolic. Based on the performance curve, the CFT with 26 blades has the highest performance for low-head conditions.

Downloads