Feasibility Study of Small-Diameter Pico-Hydro Breastshot Waterwheel by Computational Method

DOI:

https://doi.org/10.37934/cfdl.15.11.169180Keywords:

Pico-hydro, Waterwheel, Breastshot, Computational MethodAbstract

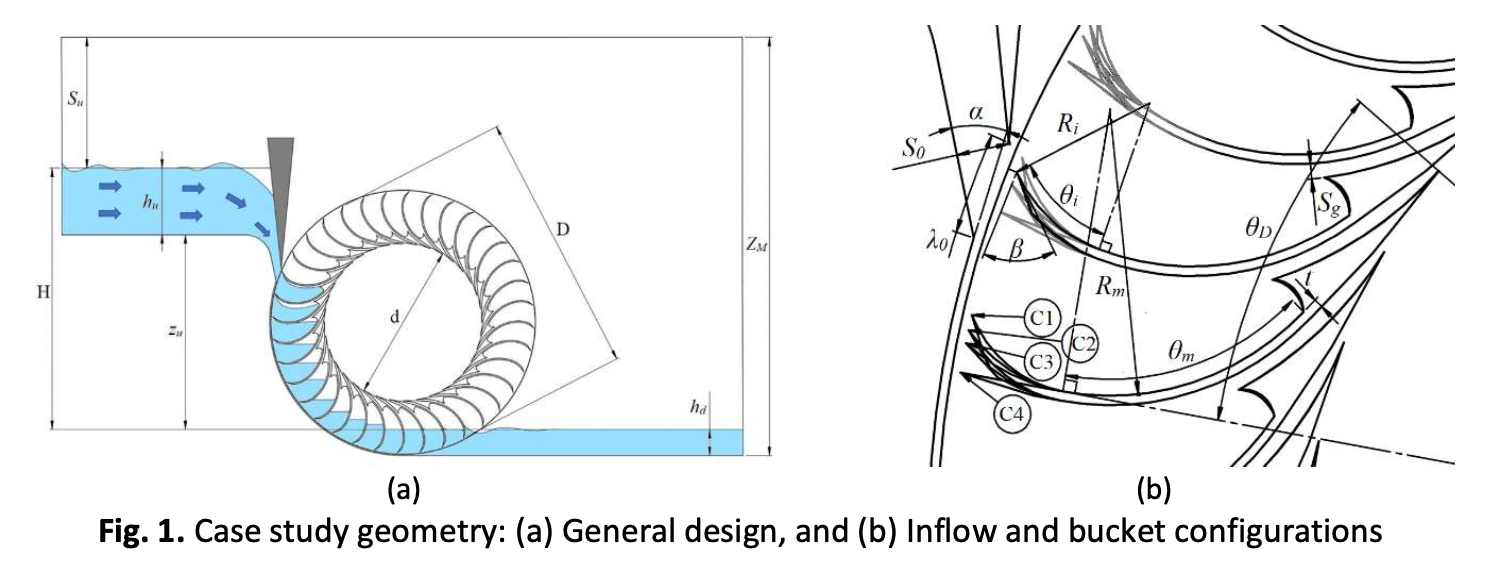

Breastshot water wheels have very good simplicity, efficiency, and low head working range which is suitable for use in tropical rainforest villages in Indonesia. One of the weaknesses of the breastshot water wheel is that it has a very slow rotational speed which makes it need a high transmission ratio to be coupled with the generator. This study investigates the performance of a breastshot water wheel at smaller diameters and modifying the bucket inlet angle (36°, 49°, 71°, and 90°) by the computational fluid dynamics (CFD) method. In this case, the breastshot waterwheel's diameter ratio is equal to the head. Based on CFD results, the new configuration (this study) allowed us to increase the rotational speed to 30 to 35 rpm, higher than typical rotational speeds of breastshot water wheels of less than 10 rpm. Then, the bucket inlet angle and wheel rotation affect the performance of the breastshot waterwheel and are expressed using empirical law. Based on the empirical law approach, the 49° bucket is recommended because it has a stable efficiency above 60% and a wide operating range; the large discharge fluctuations do not change the turbine performance significantly.

Downloads

References

Pps, Jonathan Sahat, Dendy Adanta, and Aji Putro Prakoso. "Influence of bucket shape and kinetic energy on breastshot waterwheel performance." In 2018 4th international conference on science and technology (ICST), pp. 1-6. IEEE, 2018.

Müller, Gerald, and Klemens Kauppert. "Old watermills—Britain's new source of energy?." In Proceedings of the Institution of Civil Engineers-Civil Engineering, vol. 150, no. 4, pp. 178-186. Thomas Telford Ltd, 2002. https://doi.org/10.1680/cien.2002.150.4.178

Syafriyudin, Fajar B., S. H. Winoto, and M. Facta. "Early analysis of jumping water effect on breastshot waterwheel for microhydro power plant." In J Phys Conf Ser, vol. 953, p. 12039. 2018. https://doi.org/10.1088/1742-6596/953/1/012039

Müller, Gerald, and Klemens Kauppert. "Performance characteristics of water wheels." Journal of Hydraulic Research 42, no. 5 (2004): 451-460. https://doi.org/10.1080/00221686.2004.9641215

Adanta, Dendy, Budiarso Budiarso, Warjito Warjito, Ahmad Indra Siswantara, and Aji Putro Prakoso. "Performance comparison of NACA 6509 and 6712 on pico hydro type cross-flow turbine by numerical method." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 45, no. 1 (2018): 116-127.

Helmizar, Helmizar. "Turbine wheel-a hydropower converter for head differences between 2.5 and 5 m." PhD diss., University of Southampton, 2016.

Breeze, Paul. Hydropower. Academic Press, 2018. https://doi.org/10.1016/B978-0-12-812906-7.00006-5

Müller, G., and Christian Wolter. "The breastshot waterwheel: design and model tests." In Proceedings of the Institution of Civil Engineers-Engineering Sustainability, vol. 157, no. 4, pp. 203-211. Thomas Telford Ltd, 2004. https://doi.org/10.1680/ensu.2004.157.4.203

Bach, Carl. Die Wasserräder. BoD–Books on Demand, 2013.

Quaranta, Emanuele, and Roberto Revelli. "Performance characteristics, power losses and mechanical power estimation for a breastshot water wheel." Energy 87 (2015): 315-325. https://doi.org/10.1016/j.energy.2015.04.079

Quaranta, E., and R. Revelli. "Optimization of breastshot water wheels performance using different inflow configurations." Renewable Energy 97 (2016): 243-251. https://doi.org/10.1016/j.renene.2016.05.078

Quaranta, Emanuele, and Roberto Revelli. "Hydraulic behavior and performance of breastshot water wheels for different numbers of blades." Journal of Hydraulic Engineering 143, no. 1 (2017): 04016072. https://doi.org/10.1061/(ASCE)HY.1943-7900.0001229

Adanta, Dendy, and Aji P. Prakoso. "The effect of bucketnumber on breastshot waterwheel performance." In IOP Conference Series: Earth and Environmental Science, vol. 105, no. 1, p. 012031. IOP Publishing, 2018. https://doi.org/10.1088/1755-1315/105/1/012031

Adanta, Dendy. "The effect of channel slope angle on breastshot waterwheel turbine performance by numerical method." Energy Reports 6 (2020): 606-610. https://doi.org/10.1016/j.egyr.2019.11.126

Quaranta, Emanuele, and Roberto Revelli. "Gravity water wheels as a micro hydropower energy source: A review based on historic data, design methods, efficiencies and modern optimizations." Renewable and Sustainable Energy Reviews 97 (2018): 414-427. https://doi.org/10.1016/j.rser.2018.08.033

Williamson, Sam J., Bernard H. Stark, and Julian D. Booker. "Low head pico hydro turbine selection using a multi-criteria analysis." Renewable Energy 61 (2014): 43-50. https://doi.org/10.1016/j.renene.2012.06.020

Michaelis, Klaus, Bernd‐Robert Höhn, and Michael Hinterstoißer. "Influence factors on gearbox power loss." Industrial lubrication and tribology 63, no. 1 (2011): 46-55. https://doi.org/10.1108/00368791111101830

Nelias, D., P. Sainsot, and L. Flamand. "Power loss of gearbox ball bearing under axial and radial loads©." Tribology transactions 37, no. 1 (1994): 83-90. https://doi.org/10.1080/10402009408983269

Chaudy, F. "Machines hydrauliques, Bibliothèque du conducteur de travaux publics." Vve. C. Dunod et P. Vicq (1896).

Busquet, Raymond. A manual of hydraulics. E. Arnold, 1906.

Adanta, Dendy, Mochammad Malik Ibrahim, Dewi Puspita Sari, Imam Syofii, and Muhammad Amsal Ade Saputra. "Application of the Grid Convergency Index Method and Courant Number Analysis for Propeller Turbine Simulation." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 96, no. 2 (2022): 33-41. https://doi.org/10.37934/arfmts.96.2.3341

Prakoso, Aji Putro, Dendy Adanta, and Ridho Irwansyah. "Approach for a breastshot waterwheel numerical simulation methodology using six degrees of freedom." Energy Reports 6 (2020): 611-616. https://doi.org/10.1016/j.egyr.2019.11.127

Hakim, Muhammad Luqman, Bagus Nugroho, Rey Cheng Chin, Teguh Putranto, I. Ketut Suastika, and I. Ketut Aria Pria Utama. "Drag penalty causing from the roughness of recently cleaned and painted ship hull using RANS CFD." CFD Letters 12, no. 3 (2020): 78-88. https://doi.org/10.37934/cfdl.12.3.7888

Fluent, A. N. S. Y. S. "Release 15.0, theory guide." ANSYS Inc, Canonsburg (2013).

Alfarawi, Suliman SS, Azeldin El-sawi, and Hossin Omar. "Exploring discontinuous meshing for cfd modelling of counter flow heat exchanger." Journal of Advanced Research in Numerical Heat Transfer 5, no. 1 (2021): 26-34.

Budiarso, Budiarso, Helmizar Helmizar, Warjito Warjito, Agus Nuramal, Wahyu Ramadhanu, and Dendy Adanta. "Performance of breastshot waterwheel in run of river conditions." In AIP Conference Proceedings, vol. 2227, no. 1. AIP Publishing, 2020. https://doi.org/10.1063/5.0000940