Computational Fluid Dynamics: Flow Analysis on The Effect of Different Jet Orifice Angle Multi Circular Jet for Fuel and Air Mixing

DOI:

https://doi.org/10.37934/cfdl.16.1.121137Keywords:

multiphase flow, internal flow, fuel mixing, turbulence generatorAbstract

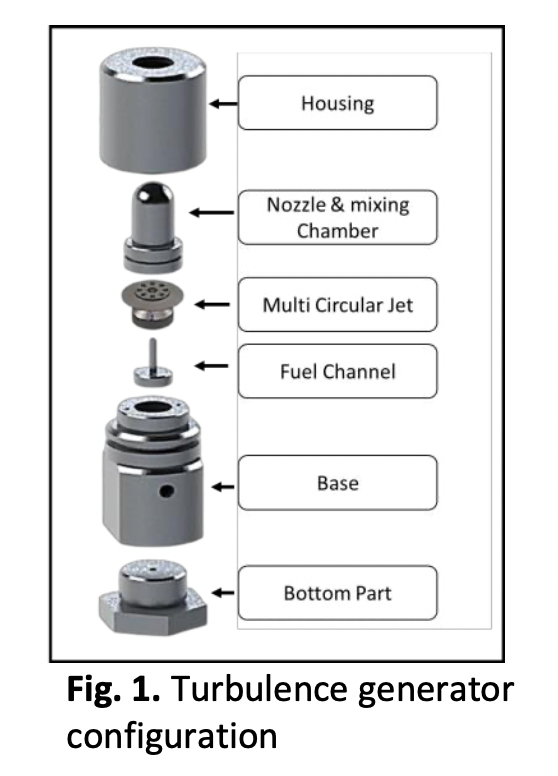

The mixing of fuel and air plays a major role in the spray and flame behavior, hence affecting the combustion performance and emissions of the internal mixing air-assisted atomizers. Air-assisted atomizers are introduced to counter the low-pressure differential of a simplex nozzle, which reduces the atomization quality. The present study aims to determine the effects of Multi Circular Jet (MCJ) plates on the geometrical configurations of internal flows in mixing chamber and the internal flow of plate 3 using different properties of fuel. In this study, the realizable k-ε turbulence model, specifically designed for strongly swirling flows, is validated through numerical simulations. The turbulence model selected is a type of Reynolds averaged Navier-Stokes (RANS) model called the k-ε model. The MCJ plates provide the primary air entrance into the mixing chamber. Additionally, it acts as a turbulence generator and can be adjusted to alter the flow of fuel and air mixtures in a mixing chamber. The study compares several MCJ geometries in terms of pressure, speed, turbulent kinetic energy, and volume fraction and compares the performances of diesel and Crude Palm Oil (CPO) B30 biodiesel fuels. The findings imply that CPO B30 biodiesel has superior atomization and mixing due to its higher density and turbulent kinetic energy. CPO B30 biodiesel was compared to Diesel in terms of maximum pressure, average speed, turbulent kinetic energy per unit mass, and volume fraction. The results indicate that CPO B30 has lower pressure and higher velocity than Diesel, suggesting better fuel atomization and mixing. The higher density of CPO B30 leads to increased turbulent kinetic energy, improving fuel-air mixing inside the combustion chamber. The study demonstrates that the use of MCJ plates can enhance mixing in a mixing chamber. In addition, MCJ plates show the ability to control the spray and atomization. The findings of this study contribute to a better understanding of the relationships between geometry and fuel-air mixing, as well as the characteristics of the internal mixing air-assisted atomizer, which will lead to future burner system improvements.

Downloads

References

Hisham Amirnordin, Shahrin, S. A. L. W. A. N. I. Ismail, Ronny Yii Shi Chin, N. O. R. A. N. I. Mansor, M. A. S. Fawzi, and A. M. I. R. Khalid. "Effects of Nozzle Diameter on the Spray Characteristics of Premix Injector in Burner System." Applied Mechanics and Materials 773 (2015): 570-574. https://doi.org/10.4028/www.scientific.net/amm.773-774.570.

Yasin, MF Mohd, R. S. Cant, C. T. Chong, and S. Hochgreb. "Discrete multicomponent model for biodiesel spray combustion simulation." Fuel 126 (2014): 44-54. https://doi.org/10.1016/j.fuel.2014.02.020.

Som, Sibendu, Anita I. Ramirez, Douglas E. Longman, and Suresh K. Aggarwal. "Effect of nozzle orifice geometry on spray, combustion, and emission characteristics under diesel engine conditions." Fuel 90, no. 3 (2011): 1267-1276. https://doi.org/10.1016/j.fuel.2010.10.048.

Yatsufusa, Tomoaki, Yoshiyuki Kidoguchi, and Daisuke Nakagawa. "Improvement of emissions and burning limits in burner combustion using an injector on the concept of fuel-water internally rapid mixing." Journal of Energy and Power Engineering 8, no. 1 (2014): 11.https://doi.org/10.17265/1934-8975/2014.01.002

Khalid, Amir, and Bukhari Manshoor. "Effect of high swirl velocity on mixture formation and combustion process of diesel spray." Applied Mechanics and Materials 229 (2012): 695-699.

https://doi.org/10.4028/www.scientific.net/AMM.229-231.695

Liu, Fengshan, Ahmet E. Karataş, Ömer L. Gülder, and Mingyan Gu. "Numerical and experimental study of the influence of CO2 and N2 dilution on soot formation in laminar coflow C2H4/air diffusion flames at pressures between 5 and 20 atm." Combustion and Flame 162, no. 5 (2015): 2231-2247. https://doi.org/10.1016/j.combustflame.2015.01.020

García, J. A., A. Lozano, J. Alconchel, E. Calvo, F. Barreras, and J. L. Santolaya. "Atomization of glycerin with a twin-fluid swirl nozzle." International Journal of Multiphase Flow 92 (2017): 150-160. https://doi.org/10.1016/j.ijmultiphaseflow.2017.03.010

Yu, Shenghao, Bifeng Yin, Weixin Deng, Hekun Jia, Ze Ye, Bin Xu, and Huaping Xu. "An experimental comparison of the elliptical and circular nozzles spray and mixing characteristics under different injection pressures." Fuel 236 (2019): 1474-1482.

Gad, H. M., E. A. Baraya, T. M. Farag, and I. A. Ibrahim. "Effect of geometric parameters on spray characteristics of air assisted pressure swirl atomizer." Alexandria Engineering Journal 61, no. 7 (2022): 5557-5571.https://doi.org/10.1016/j.aej.2021.11.010

Yatsufusa, T., T. Kumura, Y. Nakagawa, and Y. Kidoguchi. "Advantage of using water-emulsified fuel on combustion and emission characteristics." Fuel 5, no. 60 (2009).

Shriram Sathishkumar, Bommisetty Sambasiva Rao, Sidharth Pradeep, Solai Sairam R. M., Balaji Kalaiarasu, & Prabhu Selvaraj. "Modelling and Validating the Spray Characteristics of a Co-axial Twin-Fluid Atomizer Using OpenFOAM. " Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 91, no. 1 (2022): 35–45. https://doi.org/10.37934/arfmts.91.1.3545

Rasha Abdulrazzak Jasim, Qasim Hussen, W., Abdullah, M. F., & Rozli Zulkifli. "Numerical Simulation of Characterization of Hydraulic Jump Over an Obstacle in an Open Channel Flow. " Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 106, no. 1 (2023): 1–15. https://doi.org/10.37934/arfmts.106.1.115

Shu, Y., Hu, P., Adnan, I., Zhi, L., & Chen, Q. (2022). Comparison between homogeneous and separated flow models of isobutane flowing through adiabatic capillary tubes. JUSTC, 52(7), 5. https://doi.org/10.52396/JUSTC-2021-0130

Du, Zhao-bo, Wei Huang, and Li Yan. "Parametric study on mixing augmentation mechanism induced by air injection in a shock-induced combustion ramjet engine." Energy 186 (2019): 115895. https://doi.org/10.1016/j.energy.2019.115895

Zhu, Zhaoyou, Bin Qin, Shuhua Li, Yigang Liu, Xin Li, Peizhe Cui, Yinglong Wang, and Jun Gao. "Multi-dimensional analysis of turbulence models for immiscible liquid-liquid mixing in stirred tank based on numerical simulation." Separation Science and Technology 56, no. 2 (2021): 411-424. https://doi.org/10.1080/01496395.2020.1715436

Abidi, Shahim Haider, and M. M. Hasan. "Effect due to Variation in Bend Angles of Intake Manifold on Turbulent Kinetic Energy for Diesel Engine." In International Journal of Innovative Technology and Exploring Engineering (Vol. 9, Issue 5, pp. 1979–1982). Blue Eyes Intelligence Engineering and Sciences Engineering and Sciences Publication - BEIESP. https://doi.org/10.35940/ijitee.e2973.039520

Narayana Rao, K. V. L., B. V. S. S. S. Prasad, C. H. Kanna Babu, and Girish K. Degaonkar. "Influence of inlet swirl on pattern factor and pressure loss in an aero engine combustor." Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 236, no. 5 (2022): 2631-2645. https://doi.org/10.1177/09544062211027209

Eliasz, Jacek, Tomasz Osipowicz, Karol Franciszek Abramek, and Łukasz Mozga. "Model issues regarding modification of fuel injector components to improve the injection parameters of a modern compression ignition engine powered by biofuel." Applied Sciences 9, no. 24 (2019): 5479. https://doi.org/10.3390/app9245479

Sies, Mohamad Farid, Norrizal Mustaffa, Hanis Zakaria, Hamidon bin Salleh, Bukhari Manshoor, and Amir Khalid. Development of the premixing injector in burner system. Vol. 465. Trans Tech Publications Ltd, 2014. https://doi.org/10.4028/www.scientific.net/AMM.465-466.302

Amirnordin, Shahrin Hisham, Amir Khalid, Norshuhaila Mohamed Sunar, Mas Fawzi Mohd Ali, Azwan Sapit, Muhammad Ridzwan Kamaruddin, Syabillah Sulaiman, and Dr Hasan Koten. "Comparison of Spray Characteristics, Swirling Motion and Flame Development for Multi-Circular Jet and Swirl Plates." Swirling Motion and Flame Development for Multi-Circular Jet and Swirl Plates. SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4055166

Hou, Xingxia, Shaolin Wang, Pengfu Xie, Qing Gao, Chunqing Tan, and Jianwen Wang. "CFD Simulation of Combustion in Gas Turbine Engine." In 2017 5th International Conference on Frontiers of Manufacturing Science and Measuring Technology (FMSMT 2017), pp. 890-896. Atlantis Press, 2017. https://doi.org/10.2991/fmsmt-17.2017.170

Zhang, Yang, and Maarten Vanierschot. "Modeling capabilities of unsteady RANS for the simulation of turbulent swirling flow in an annular bluff-body combustor geometry." Applied Mathematical Modelling 89 (2021): 1140-1154. https://doi.org/10.1016/j.apm.2020.07.037

Wan Rosli, W. M. A., & Padzillah, M. H. "Investigation on the Flow Angle of a Mixed Flow Turbocharger Turbine Under Steady State Operating Conditions." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 99, No.1 (2022): 104–113. https://doi.org/10.37934/arfmts.99.1.104113

Du, Bingxuan, and Zhenfeng Zhao. "Numerical prediction of the spray from an air-assisted fuel injection system via Eulerian–Lagrangian approach." Energy Reports 7 (2021): 6718-6732. https://doi.org/10.1016/j.egyr.2021.09.128

Hou, Xingxia, Shaolin Wang, Pengfu Xie, Qing Gao, Chunqing Tan, and Jianwen Wang. "CFD Simulation of Combustion in Gas Turbine Engine." In 2017 5th International Conference on Frontiers of Manufacturing Science and Measuring Technology (FMSMT 2017), pp. 890-896. Atlantis Press, 2017. https://doi.org/10.2991/fmsmt-17.2017.170