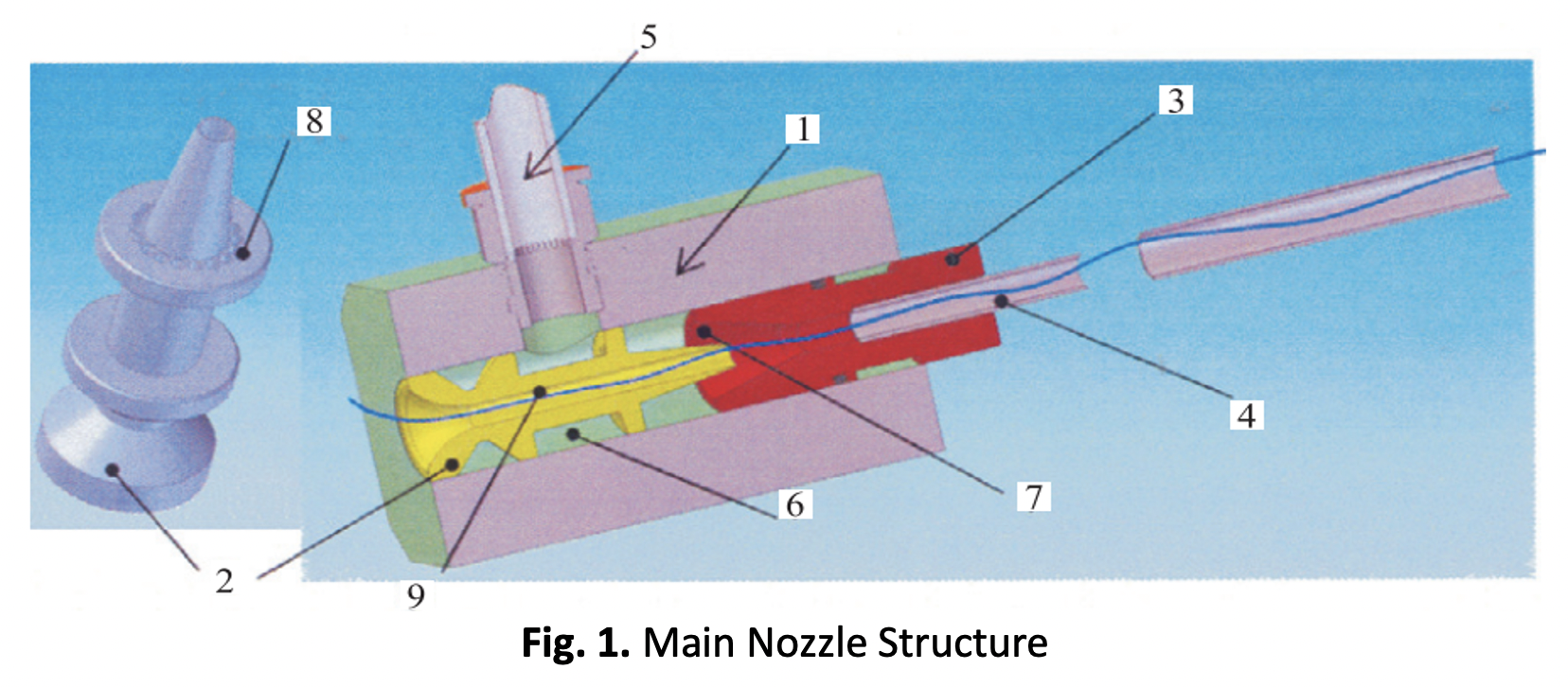

New Designed Main Nozzle of Air-Jet Weaving Machine for Optimizing Air Consumption using CFD Simulation

DOI:

https://doi.org/10.37934/cfdl.14.9.108117Keywords:

Main nozzle, Air consumption, Acceleration tube, CFD (Computational fluid dynamics), Throat, Air inletAbstract

The air-jet weaving machine is widely used in the textile industry and the main nozzle and acceleration tube is one of its key components of the machine. In this paper, the influence of some parameters, including the input air pressure with air inlet length and the structure of the nozzle core and its internal diameter, on the internal flow field of the main nozzle is analyzed to get the velocity of flow at the optimum air pressure that optimizing the air consumption. The flow field inside an air-jet loom main nozzle is studied by simulating the design of the main nozzle and acceleration tube, by means of a two-dimensional model implemented in the Ansys computational fluid dynamics (CFD) code Fluent, by designing the new main nozzle by working on the structural geometry of the main nozzle and acceleration tube. In order to determine the optimum air pressure for the required air velocity with optimum air consumption to flow weft yarn in an air-jet weaving machine.