Manufacturing Study on Different Glue Spread and Press Pressure for Glued Laminated Timber Made from Laran

DOI:

https://doi.org/10.37934/aram.107.1.2029Keywords:

Glue laminated timber, press pressure, adhesive spread rate , delamination test, block shear test, RSMAbstract

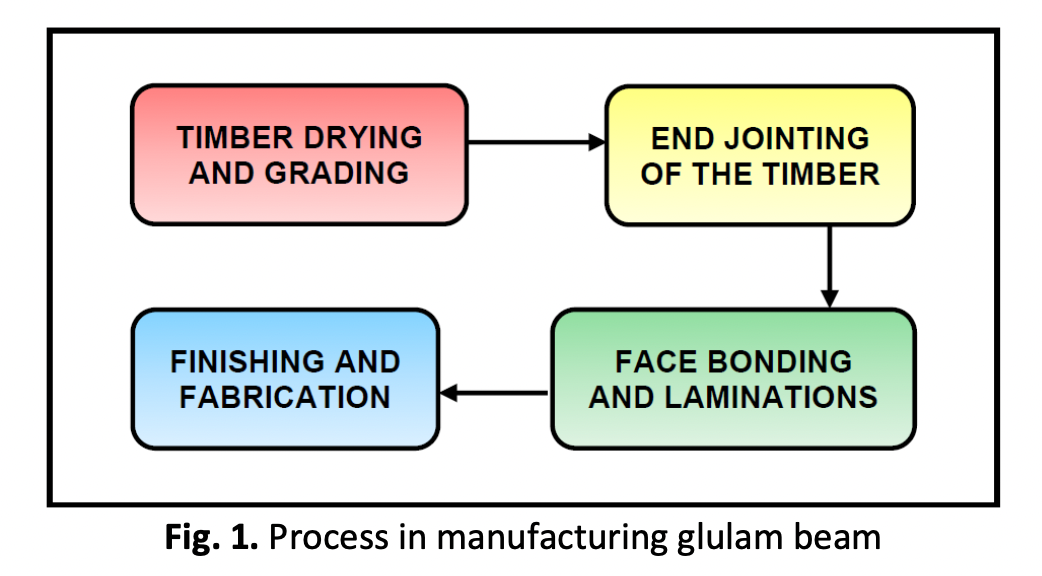

Amidst challenges such as dwindling timber log supply from natural forests, concerns about timber quality, and rising timber costs, the timber industry has increasingly turned to engineered lumber solutions, including glued laminated timber (glulam) crafted from fast-growing species. However, the performance of glulam derived from plantation trees, notably swift-growing varieties like Laran, remains an area warranting exploration. This study addresses critical aspects of glulam production, encompassing adhesive selection, spread rate, and press pressure, which collectively influence material performance. The objectives of this research encompass an assessment of the bonding integrity of glulam originating from Laran plantation species and an evaluation of the optimal adhesive spread rate and press pressure for Laran-derived glulam. Various adhesive spread rates (200 g/m2, 250 g/m2, 350 g/m2 and 400 g/m2) and press pressures (0.7, 1.0 and 1.4 MPa), utilizing Phenol-Resorcinol Formaldehyde (PRF) adhesives, were systematically investigated in alignment with the guidelines stipulated in MS 758: 2020. Bonding integrity was evaluated via block shear and cyclic delamination tests. The study reveals that these parameters indeed exert a tangible influence on the bonding efficacy of PRF adhesive with Laran species. Remarkably, an optimal adhesive spread rate of 399.78 g/m2 and press pressure of 1.18 MPa emerged as pivotal thresholds for superior bonding outcomes. Notably, the significance of adeptly designed glulam beams within wooden structural frameworks is underscored, particularly in light of the multifaceted imperatives of sustainability, economics, and environmental conscientiousness.

Downloads